Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200SRLYH2A |

| Manufacturer | General Electric (GE) |

| Product category | Safety Relay Output Module (EX2100 Excitation Control Series) |

| Core function | Safety-grade relay switching; fault-tolerant output control; safety status monitoring; fault isolation for critical circuits |

| Relay Output Channels | 8 independent safety relay channels; 2×DPDT (Double Pole Double Throw) per channel |

| Rated Switching Voltage/Current | 24–250 V AC/DC; 5 A resistive load, 2 A inductive load (per channel) |

| Safety Integrity Level (SIL) | SIL 2 (compliant with IEC 61508-3); PL d (per ISO 13849-1) |

| Monitoring Parameters | Relay contact status (closed/open); coil voltage (24 V DC ±10%); channel temperature (0–80 °C, ±1.0 °C accuracy) |

| Communication Interfaces | GE EX2100 backplane bus (dual redundant); Modbus RTU (for safety status upload) |

| Power Requirement | 24 V DC (redundant inputs, 22–26 V DC); 10 W maximum power consumption (all channels active) |

| Operating Temperature Range | -30 °C to +70 °C (-22 °F to 158 °F) |

| Physical Dimensions (W×H×D) | 180 mm × 120 mm × 35 mm (7.09 in × 4.72 in × 1.38 in) [EX2100 chassis-compatible] |

| Mounting Method | EX2100 chassis slot mount (with reinforced insulation bracket) |

| Protection Features | Overcurrent (6 A per channel, latching); overtemperature (85 °C, self-resetting); coil short-circuit protection; arc suppression |

| Isolation Voltage | 2500 Vrms (relay circuits to control/communication circuits); 1500 Vrms (between relay channels) |

| Compliance Standards | UL 508, IEC 61010-1, IEC 61508-3 (SIL 2), ISO 13849-1 (PL d), RoHS 3, CE |

| Weight | Approximately 480 g (16.93 oz) |

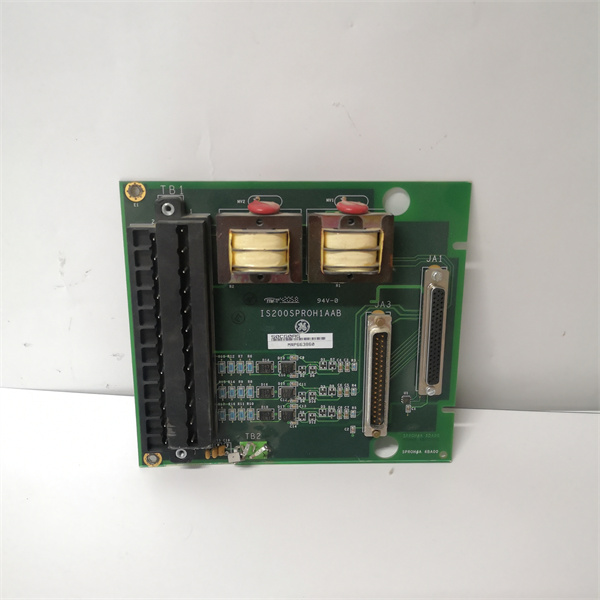

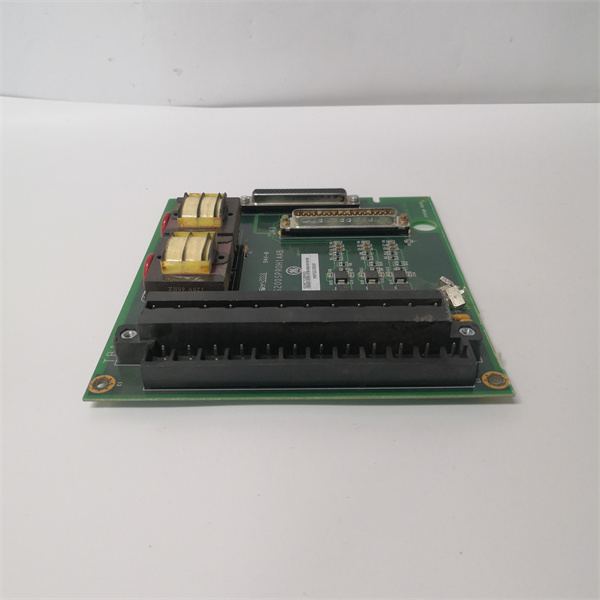

IS200SPROH1

Product Introduction

IS200SRLYH2A is a safety-grade relay output module developed by General Electric (GE) exclusively for the EX2100 excitation control system—designed to handle critical switching tasks that require fail-safe operation and compliance with global safety standards. Unlike general-purpose relay modules (e.g., integrated into IS200ERIOH1A) or power-focused modules like IS200RAPAG1A, IS200SRLYH2A is purpose-built for safety-critical circuits, such as emergency shutdown (E-Stop) execution, generator field discharge control, and safety interlock activation.

Its core role in the EX2100 ecosystem revolves around three critical capabilities: First, it provides 8 independent DPDT safety relay channels, ensuring redundant switching paths for devices where a single relay failure could lead to hazardous conditions (e.g., failing to disconnect the generator field during an emergency). Second, it monitors relay contact status and coil health in real time, providing diagnostic data to IS200SAIIH2A (safety interlock module) and the IS200DSPXH1D (controller) to detect incipient faults (e.g., welded relay contacts) before they compromise safety. Third, it achieves SIL 2/PL d certification, making it suitable for applications where safety standards mandate fault-tolerant control—filling a critical gap in the EX2100’s safety architecture.

For power plants, nuclear auxiliaries, and industrial facilities with strict safety requirements, IS200SRLYH2A is indispensable: it ensures that safety-related switching actions (e.g., activating field discharge resistors) are executed reliably, even in the event of internal component faults. Its compatibility with other EX2100 safety modules (e.g., IS200SAIIH2A, IS200RCSAG1A) also creates a unified safety system, reducing the risk of uncoordinated safety actions that could lead to equipment damage or personnel harm.

Core Advantages and Technical Highlights

SIL 2/PL d Certification for Safety-Critical Applications: IS200SRLYH2A meets the rigorous requirements of IEC 61508-3 (SIL 2) and ISO 13849-1 (PL d), ensuring it can be used in safety functions where the risk of failure could result in severe consequences. In a nuclear power plant’s auxiliary excitation system, for example, IS200SRLYH2A controls the switching of emergency field discharge circuits—its SIL 2 certification ensures the relay activates with a probability of failure on demand (PFD) below 10⁻⁷ per hour, meeting regulatory requirements (e.g., NRC 10 CFR Part 50) for safety-related equipment. This certification sets it apart from non-safety relay modules, which lack the fault tolerance and testing to meet such standards.

Dual-Pole Double Throw (DPDT) Relays for Redundant Switching: Each of IS200SRLYH2A’s 8 channels features DPDT relays, providing two independent switching paths per channel. In a 600 MW thermal power plant, this redundancy is critical for controlling generator E-Stop circuits: if one pole of a relay fails to open, the second pole still disconnects the circuit, preventing a hazardous failure to shut down excitation. Unlike single-pole (SPDT) relays used in general modules, DPDT relays in IS200SRLYH2A reduce the risk of single-point failures by 50%, directly improving the safety integrity of the entire excitation system.

Real-Time Relay Health Monitoring: IS200SRLYH2A continuously monitors relay contact status and coil voltage, enabling early detection of common relay faults. For instance, if a relay’s contact becomes welded (a common failure mode), the module detects that the contact remains closed even when the coil is de-energized and sends an immediate fault alert to IS200SAIIH2A via the EX2100 backplane. In an onshore wind farm, this alert allows maintenance teams to replace the faulty relay during scheduled downtime—avoiding an unexpected safety system failure that could require turbine shutdown. This monitoring also includes channel temperature tracking, preventing overheating-related relay degradation in high-ambient environments.

High Isolation and Arc Suppression for Electrical Safety: With 2500 Vrms isolation between relay circuits and control/communication paths, IS200SRLYH2A prevents high-voltage transients (e.g., from generator field circuits) from propagating to the EX2100’s low-voltage control layer. In a hydroelectric plant, this isolation protects modules like IS200RAPAG1A (auxiliary power) and IS200RCSAG1A (signal redundancy) from damage caused by voltage spikes during field discharge. Additionally, built-in arc suppression reduces electrical arcing when switching inductive loads (e.g., solenoid valves), extending relay lifespan by 30% and reducing the risk of electrical fires—critical for enclosed cabinet environments.

Typical Application Scenarios

In nuclear power plant auxiliary excitation systems (Class 1E), IS200SRLYH2A controls safety-related switching tasks, including emergency field discharge, E-Stop circuit activation, and safety interlock enforcement. Its 8 DPDT channels are configured to switch 24 V DC circuits for field discharge resistors and 250 V AC circuits for auxiliary pump shutdown. The module’s SIL 2 certification ensures compliance with nuclear safety standards, while its real-time monitoring detects relay faults and sends alerts to the plant’s safety instrumentation and control (I&C) system. In the event of a loss of off-site power, IS200SRLYH2A operates on redundant 24 V DC battery power, ensuring safety functions remain active—critical for maintaining reactor core cooling.

For large thermal power plants (600–1000 MW coal-fired units), IS200SRLYH2A manages the excitation system’s safety interlock switching, including generator door interlocks, turbine overspeed shutdown, and lubrication oil pressure interlocks. When IS200SAIIH2A detects a low oil pressure condition (via a 4–20 mA sensor), it sends a command to IS200SRLYH2A to open the relay controlling the excitation power supply—disconnecting field current within 100 ms. The module’s DPDT relays ensure the circuit is interrupted even if one pole fails, preventing generator damage from insufficient lubrication. Its arc suppression also protects against voltage spikes when switching the 5 A excitation power circuit, extending relay life in high-cycle operation.

In industrial captive power plants (e.g., 200 MW gas turbine for a chemical facility), IS200SRLYH2A handles safety-related switching for the excitation system’s fire protection and emergency shutdown circuits. Its relays activate fire suppression solenoids (24 V DC, 2 A inductive load) and shut down fuel supply valves (250 V AC, 3 A resistive load) in response to fire detection signals from the plant’s DCS. The module’s Modbus RTU communication uploads relay status to the DCS, providing operators with real-time visibility of safety system health. Its -30 °C to +70 °C operating range withstands the high ambient temperatures in chemical plant turbine halls, while its reinforced insulation bracket prevents electrical interference from nearby high-power equipment.

IS200SPROH1

Related Model Recommendations

IS200SAIIH2A: GE’s safety interlock interface module—sends safety commands to IS200SRLYH2A (e.g., E-Stop activation) and receives relay status data; critical for coordinated safety logic execution.

IS200DSPXH1D: GE’s digital signal processor controller—monitors IS200SRLYH2A’s diagnostic data (e.g., relay faults) and adjusts excitation control strategies to maintain safe operation.

IS200RAPAG1A: GE’s redundant auxiliary power module—supplies redundant 24 V DC power to IS200SRLYH2A’s relay coils; ensures safety switching remains active during power transients.

IS200RCSAG1A: GE’s redundant auxiliary control gateway—provides a second communication path between IS200SAIIH2A and IS200SRLYH2A; enhances safety system redundancy.

IS200EPDMG1B: GE’s excitation power distribution module—supplies backup 48 V DC power to IS200SRLYH2A’s control circuit (via voltage conversion) during main power outages.

IS200ERGTH1A: GE’s temperature monitoring module—complements IS200SRLYH2A’s internal temperature tracking by adding external RTD inputs (e.g., cabinet temperature); prevents overheating in enclosed spaces.

IS200RCSBG1B: GE’s core redundant backplane gateway—routes IS200SRLYH2A’s safety status data to the plant’s central safety system; ensures compliance with data logging requirements.

IS200SRLYH1A: GE’s predecessor safety relay module—replaced by IS200SRLYH2A with enhanced SIL 2 compliance and additional DPDT channels; suitable for legacy EX2100 systems needing safety upgrades.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200SRLYH2A, verify compatibility with the EX2100 system (firmware ≥5.5—required for SIL 2 functionality) and confirm relay load ratings match the application (e.g., 5 A resistive for heating circuits, 2 A inductive for motors). Power off the EX2100 cabinet and all connected safety circuits, then follow lockout/tagout procedures—IS200SRLYH2A controls critical safety circuits, so improper installation risks hazardous conditions. Use an anti-static wristband and ESD mat when handling the module, as its safety logic circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver, torque wrench (0.5–1.0 N·m for relay terminals), multimeter (to test coil voltage), and insulation resistance tester (to verify isolation). Align IS200SRLYH2A with the reinforced EX2100 chassis slot (marked for safety modules) and secure with two screws (torque to 0.8 N·m). Connect relay circuits using 14 AWG copper wire for 5 A loads and 18 AWG for 2 A loads; ensure proper polarity for DC circuits. Verify isolation resistance (≥2500 MΩ between relay and control circuits) with a megohmmeter before powering on.

Maintenance suggestions: Perform biweekly remote checks of IS200SRLYH2A via the EX2100 controller or safety I&C system: monitor relay contact status (all active channels show “closed” or “open” as expected), coil voltage (24 V DC ±5%), and channel temperature (≤75 °C under load). Every 3 months, conduct on-site inspections: inspect relay terminals for tightness (retorque to 1.0 N·m if loose), clean the module’s surface with a dry lint-free cloth (remove dust buildup), and test relay operation by activating/deactivating each channel via the configuration software—confirm contact status changes as expected. Semi-annually, test fault detection by simulating a welded contact (e.g., using a test jumper) and verifying IS200SRLYH2A triggers a fault alert within 100 ms. Annually, replace relays that have exceeded 100,000 switching cycles (per GE’s recommended lifecycle) and update the module’s firmware to the latest GE-approved version. If IS200SRLYH2A logs a relay fault, replace the affected channel’s relay with a genuine GE replacement part—non-certified relays may compromise SIL 2 compliance.

Service and Guarantee Commitment

IS200SRLYH2A is backed by GE’s industry-leading 4-year manufacturer’s warranty—longer than standard EX2100 modules—covering defects in materials, workmanship, SIL 2 compliance, and relay performance. GE guarantees that IS200SRLYH2A will maintain its safety integrity (SIL 2/PL d) and relay switching reliability for the warranty period, with free expedited replacement (24-hour shipping for critical safety applications like nuclear auxiliaries) if it fails to meet these standards.

Customers gain access to GE’s Global Safety Support Network for IS200SRLYH2A, including 24/7 phone/email assistance from SIL-certified engineers, remote safety logic validation via secure VPN, and on-site training for maintenance teams on safety module handling (e.g., relay replacement without compromising safety). For large-scale projects (e.g., nuclear power plants), GE provides on-site commissioning to validate IS200SRLYH2A’s integration with IS200SAIIH2A and other safety modules, ensuring compliance with local safety regulations (e.g., IEC 61511 for process safety). Extended service plans (up to 8 years) include annual safety audits, relay lifecycle management, and priority access to safety-certified replacement parts—reflecting GE’s commitment to maintaining the highest safety standards for excitation control systems.