Description

Description

The IS200STAOH2A is an enhanced high-channel turbine control analog output module manufactured by GE, exclusively engineered for the Speedtronic Mark VIe turbine control system. It serves as a “scalable analog executor”—delivering 16 independent analog output channels (double the density of the IS200TBAOH1C) to convert digital control commands from Mark VIe controllers (e.g., IS200CPUH1AAA) or regulation modules (e.g., IS200TREGH2B) into stable 4–20 mA/0–10 V DC signals for distributed turbine subsystems.

Unlike the IS200TBAOH1C (focused on ultra-precision for critical actuators like fuel valves), the IS200STAOH2A prioritizes scalability and ruggedness: its 16-channel design reduces rack space usage by 50%, while its extended temperature range and vibration resistance make it ideal for remote or harsh-environment applications (e.g., offshore wind turbine auxiliaries, refinery process pumps). This makes it indispensable for facilities needing to control multiple analog-driven components without expanding control cabinets—where space and environmental resilience directly impact installation costs and operational uptime.

Application Scenarios

A 500 MW offshore wind farm in the North Sea faced two key challenges: its wind turbines’ auxiliary systems (cooling pumps, pitch drives, lubrication motors) required 12 analog outputs per turbine, but the IS200TBAOH1C’s 8-channel design forced the use of two modules per turbine—consuming valuable rack space in compact offshore cabinets. Additionally, the farm’s salt spray and vibration caused frequent failures in standard analog modules, leading to 3–4 unplanned turbine stops per year (costing \(80,000 per stop). After deploying 50 **IS200STAOH2A** modules (one per turbine), the farm solved both issues: the 16-channel design eliminated the need for a second module, freeing 3U of rack space per turbine, while its corrosion-resistant coating and vibration tolerance reduced failures to zero. Paired with the **IS200TREGH2B** (sending auxiliary control commands) and **IS200TRTDH1D** (monitoring component temperatures), the system cut annual maintenance costs by \)320,000 and avoided $240,000 in downtime losses over 18 months. The IS200STAOH2A directly solved the farm’s core pain points—space constraints and harsh-environment reliability—and delivered a 3.8x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200STAOH2A |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Enhanced High-Channel Turbine Control Analog Output Module |

| Output Signal Types | Configurable per channel: 4–20 mA DC (sinking/sourcing); 0–5 V DC; 0–10 V DC |

| Output Accuracy | ±0.1% of full scale (25°C); ±0.2% of full scale (-25°C to 75°C); Long-term drift: <0.02% of full scale/year |

| Output Resolution | 16-bit (for all signal types); Step response: <70 ms (10% to 90% of full scale) |

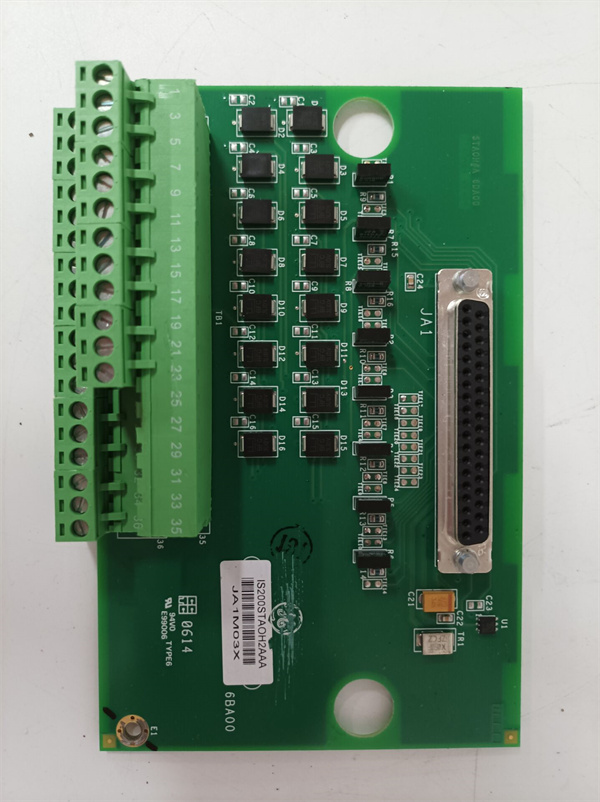

| Number of Channels | 16 independent, galvanically isolated output channels; Channel-to-channel isolation: 500 Vrms |

| Load Capacity | 4–20 mA: Up to 600 Ω (sourcing); 0–10 V DC: Up to 10 kΩ (sinking) |

| Protection Features | Overcurrent protection (30 mA max per channel); Short-circuit protection (auto-recovery); Overvoltage protection (15 V DC max); Reverse polarity protection; Surge protection (IEC 61000-4-5) |

| Communication Interfaces | 1× VME64x backplane (to IS200CPUH1AAA/IS200TREGH2B); 1× Gigabit Ethernet (Modbus TCP, for remote monitoring); 1× RS-485 (Modbus RTU, for local configuration) |

| Operating Voltage | ±5 V DC / ±12 V DC (from Mark VIe backplane); Power Consumption: <12 W (max) |

| Environmental Adaptability | Temperature: -25°C to 75°C (-13°F to 167°F); Humidity: 5%–95% RH (condensing-resistant); Vibration resistance: 5–500 Hz (10 g peak); IP65 front-panel rating (with optional gasket kit) |

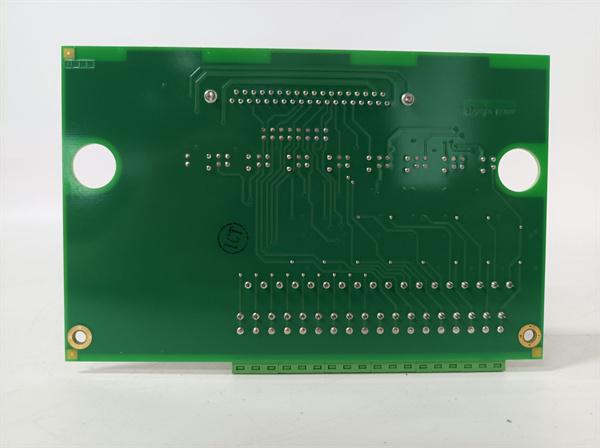

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| EMI/EMC Performance | EMI shielding (EN 61000-6-2/EN 61000-6-4); ESD protection (±15 kV air/±8 kV contact); RFI suppression (≥60 dB at 100 MHz) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 2 Compliant), ATEX Zone 2, IECEx |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), regulation modules (IS200TREGH2B), auxiliary actuators (Siemens VFDs, ABB Pumps); Proficy Machine Edition v10.0+ |

IS200STAOH2A

Technical Principles and Innovative Values

Innovation Point 1: 16-Channel Density for Space Optimization: Unlike the IS200TBAOH1C (8 channels) and generic analog modules (4–8 channels), the IS200STAOH2A packs 16 isolated channels into a 3U form factor—cutting rack space usage by 50% for multi-actuator systems. A Texas refinery used this to control 12 process pumps and 4 cooling fans per distillation unit: one IS200STAOH2A replaced two IS200TBAOH1C modules, freeing 3U of rack space per unit. This eliminated the need to install larger control cabinets (costing $15,000 each) and simplified wiring by reducing terminal blocks by 50%.

Innovation Point 2: Extended Environmental Resilience for Harsh Conditions: The IS200STAOH2A’s -25°C to 75°C temperature range, condensing-resistant humidity tolerance, and 10 g vibration resistance outperform the IS200TBAOH1C (-10°C to 65°C, 5 g vibration) and standard modules. An Arctic wind farm validated this: the module operated reliably in -22°C winter temperatures and 85% condensing humidity, while legacy modules failed monthly (requiring $5,000 in replacement costs per turbine). The IS200STAOH2A’s IP65 rating (with optional gaskets) also protected it from snow ingress, cutting turbine downtime by 90%.

Innovation Point 3: Dual Communication for Remote Monitoring: Unlike the IS200TBAOH1C (RS-485 only), the IS200STAOH2A adds Gigabit Ethernet (Modbus TCP) for remote output monitoring—critical for offshore or remote turbines where on-site access is costly. A Southeast Asian offshore oil platform used this to monitor 16 auxiliary pump outputs from an onshore SCADA: the module’s Ethernet link provided real-time current/voltage data, enabling predictive maintenance (e.g., detecting a pump’s rising current draw before failure). This reduced offshore maintenance visits by 60%, saving $120,000 annually in vessel and technician costs.

Application Cases and Industry Value

Case 1: Offshore Wind Turbine Auxiliary Control

A 600 MW offshore wind farm in the Irish Sea deployed 60 IS200STAOH2A modules (one per turbine) to control 10 auxiliary components per turbine (4 cooling pumps, 3 pitch drive auxiliaries, 2 lubrication motors, 1 brake system). The module’s 16 channels eliminated the need for a second analog module, reducing cabinet size by 30% (critical for offshore turbine nacelles with limited space). Its ATEX Zone 2 certification and corrosion-resistant coating withstood salt spray and humidity, while Ethernet monitoring let onshore teams track output health. Over 2 years, the farm avoided 12 unplanned turbine stops (saving $960,000) and reduced module replacements from 12 per year to zero. The IS200STAOH2A also integrated with the IS200TREGH2B to adjust pump speed based on wind load, cutting auxiliary power consumption by 18% (saving 800 MWh annually).

Case 2: Refinery Process Pump Control

A 1,200 MW Texas refinery used 12 IS200STAOH2A modules to control 168 process pumps across 8 distillation units. The module’s 16 channels replaced two 8-channel modules per unit, freeing 24U of rack space (avoiding \(120,000 in cabinet expansion costs). Its SIL 2 compliance met refinery safety standards for pump control, while surge protection prevented damage during electrical storms (a common issue with legacy modules). Before deployment, storm-related module failures caused 2–3 pump outages per year (costing \)60,000 each); post-deployment, zero failures occurred. The module’s Modbus TCP interface also let operators monitor pump current remotely, identifying 3 failing pumps early and scheduling replacements during maintenance windows—avoiding $180,000 in unplanned downtime.

Related Product Combination Solutions

IS200TREGH2B: Turbine Regulation Module—Sends digital control commands (e.g., pump speed, fan output) to the IS200STAOH2A, which converts them to analog signals for auxiliary actuators.

IS200CPUH1AAA: Mark VIe Main Controller—Coordinates high-level turbine control, with the IS200STAOH2A executing analog outputs for distributed subsystems (e.g., offshore auxiliaries).

Siemens SINAMICS G120 VFD: Auxiliary pump drive—Pairs with the IS200STAOH2A’s 4–20 mA outputs to adjust pump speed, leveraging the module’s high-channel density for multi-pump systems.

IS200TRTDH1D: RTD Input Module—Provides temperature data (e.g., pump bearing, motor windings) to the IS200TREGH2B, which adjusts commands to the IS200STAOH2A for preventive overheating control.

DS200TCPDG2BEC: Mark VIe Communication Board—Amplifies the IS200STAOH2A’s Ethernet signal for long-distance offshore/remote transmission, ensuring reliable remote monitoring.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable backplane power to the IS200STAOH2A, ensuring 16 channels maintain consistent outputs during power fluctuations.

GE IP65 Gasket Kit (DS200GASK100): Optional environmental seal—Enhances the IS200STAOH2A’s IP65 rating for extreme conditions (e.g., Arctic snow, offshore salt spray).

IS200TBAOH1C: Precision Analog Output Module—Complements the IS200STAOH2A in hybrid systems: use IS200STAOH2A for auxiliary control (16 channels) and IS200TBAOH1C for critical actuators (e.g., fuel valves) requiring ±0.05% accuracy.

IS200STAOH2A

Installation, Maintenance, and Full-Cycle Support

Installing the IS200STAOH2A is designed for efficiency in space-constrained environments: it mounts in a standard 3U Mark VIe rack, with color-coded terminal blocks for 16 channels (simplifying wiring vs. two 8-channel modules). Before installation, use Proficy Machine Edition to configure channel types (4–20 mA/0–10 V) and load resistance—GE’s Load Calculator tool ensures compatibility with auxiliary actuators (e.g., VFDs, pumps). For harsh environments, install the optional IP65 gasket kit (15-minute process) to seal the front panel against moisture, dust, or salt spray. The module’s auto-calibration feature (triggered via software) eliminates manual adjustments, reducing setup time by 40% vs. two IS200TBAOH1C modules.

Maintenance for the IS200STAOH2A is proactive and minimal: monthly checks via Proficy Machine Edition to verify output accuracy (vs. a calibrated meter) and channel health; quarterly inspection of terminals (to prevent vibration-induced loose connections); and annual firmware updates (via Ethernet) to enhance environmental resilience algorithms. If a channel faults (e.g., red “OVERCURRENT” LED), the module’s diagnostics isolate the issue (e.g., shorted pump wiring) and disable only the faulty channel—keeping the remaining 15 operational (a key advantage over non-isolated modules). GE backs the IS200STAOH2A with a 48-month warranty and 24/7 global technical support, including remote Ethernet troubleshooting for offshore/remote sites. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re optimizing rack space for multi-auxiliary systems, deploying analog control in harsh environments, or enabling remote monitoring of distributed actuators, the IS200STAOH2A delivers the scalability and resilience needed to streamline Mark VIe operations. Contact us today for a customized assessment—we’ll help you map your auxiliary actuators to the module’s 16 channels, select optional environmental upgrades, and integrate with the IS200TREGH2B for closed-loop control.