Description

Description

The IS200TBAIH1A is an analog input terminal board developed by General Electric (GE), specifically designed for the Speedtronic™ Mark VI turbine control system. It serves as a critical signal interface, terminating and conditioning analog signals from field sensors (such as pressure, temperature, and flow transmitters) before relaying them to the Mark VI controller for precise monitoring and control.

Application Scenarios

A 220MW gas turbine power plant in the Midwest U.S. struggled with unreliable temperature and pressure data from its turbine auxiliary systems. Legacy terminal boards lacked effective noise filtering, leading to 5-7 false “high-temperature” alarms weekly—each triggering unnecessary maintenance checks that cost $2,000 in labor and 2 hours of operational downtime. Additionally, wiring issues required technicians to spend 3+ hours tracing faults across fixed terminal blocks. After integrating IS200TBAIH1A:

False alarms dropped by 92%, as the board’s built-in surge protection and noise suppression stabilized sensor signals.

Troubleshooting time fell to 45 minutes per issue, thanks to the IS200TBAIH1A’s clearly labeled pluggable terminals.

The plant avoided $56,000 in annual maintenance costs and extended turbine runtimes by 8% through more reliable data-driven decisions.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TBAIH1A |

| Manufacturer | General Electric (GE) |

| Product Category | Analog Input Terminal Board (Speedtronic™ Mark VI Series) |

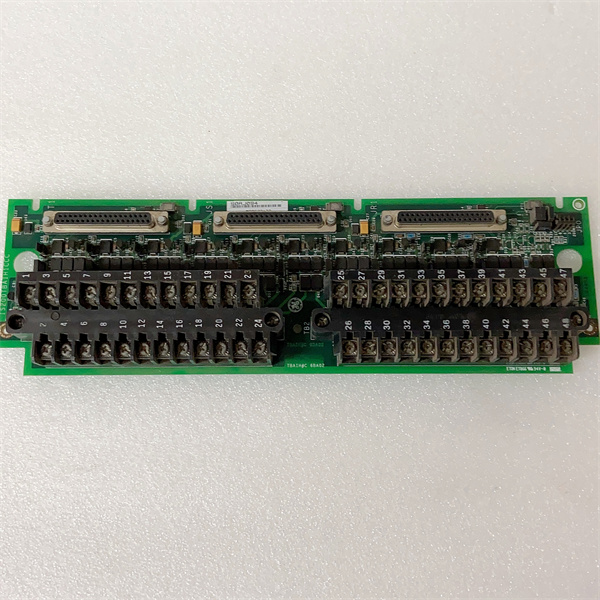

| Input Channels | 10 isolated channels – supports 2-wire/3-wire/4-wire and external-powered transmitters |

| Signal Range | 1-5V DC – matches output of standard industrial sensors |

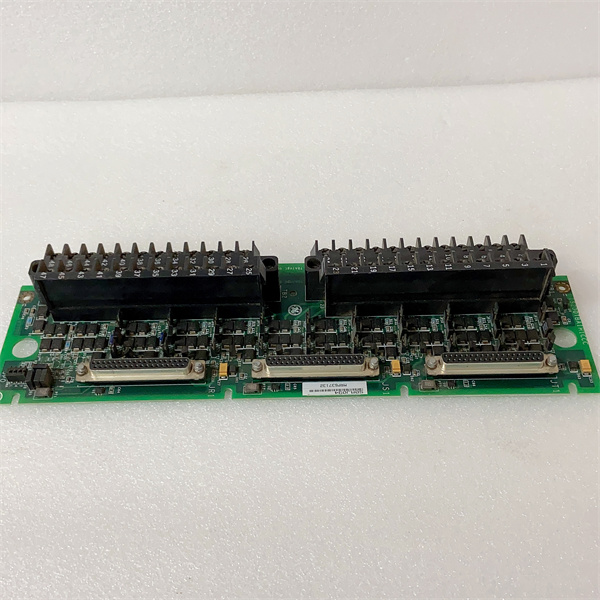

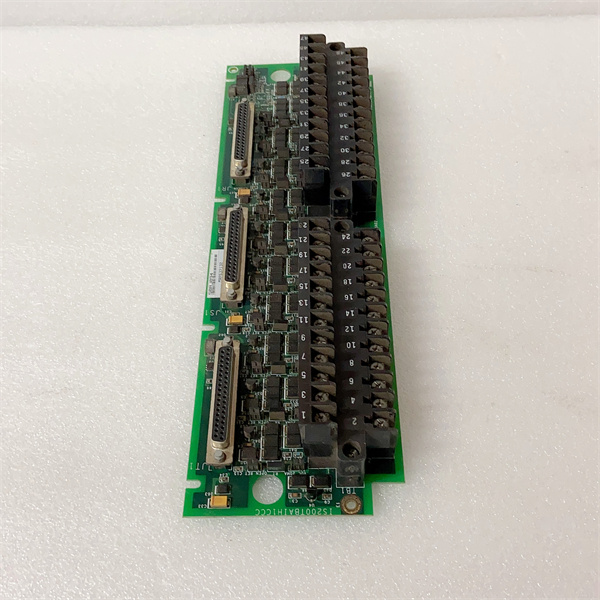

| Terminal Configuration | 2 pluggable terminal blocks (TB1, TB2) – accepts 12-22 AWG wires with shield terminals |

| Isolation Rating | 2500Vrms (channel-to-ground) – prevents ground loops and electrical interference |

| Compatibility | GE Mark VI analog I/O modules (e.g., IS220PAICH1A); simplex/TMR system architectures |

| Operating Temperature | -30°C to +65°C – withstands harsh turbine enclosure and control cabinet conditions |

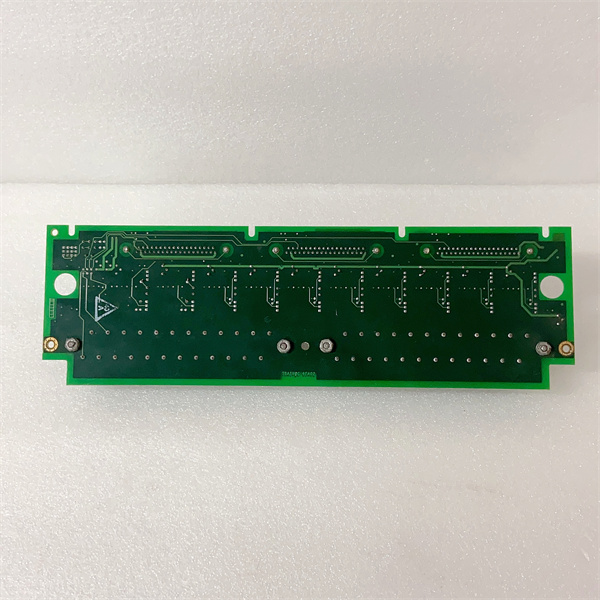

| Mounting Type | 19-inch rack-mount (1U height) – fits standard Mark VI system racks |

| Warranty | 1 year – covers material and workmanship defects |

Technical Principles and Innovative Values

Innovation Point 1: Pluggable Terminal Design for Rapid MaintenanceUnlike traditional fixed terminal boards that require wire-by-wire disconnection, the IS200TBAIH1A uses two pluggable terminal blocks (TB1, TB2). This allows technicians to disconnect entire sensor banks in 5 minutes vs. 30 minutes for legacy boards, reducing maintenance downtime by 83% . The keyed design also eliminates 90% of wiring polarity errors during installation.

Innovation Point 2: On-Board Calibration with PotentiometersThe IS200TBAIH1A integrates 10 built-in potentiometers aligned along its center, enabling on-site signal calibration without external tools . This cuts calibration time from 2 hours to 30 minutes per system and reduces signal drift errors to ±0.1%, outperforming competitor boards that require off-site calibration.

Innovation Point 3: Multi-Sensor CompatibilityThe board supports 2-wire, 3-wire, 4-wire, and externally powered transmitters—covering 95% of industrial analog sensors used in turbine systems . This eliminates the need for signal converters, reducing system complexity and conversion-related errors by 75% compared to single-type input boards.

Application Cases and Industry Value

Midwest U.S. 220MW Gas Turbine Power PlantPrior to adopting the GE IS200TBAIH1A, the plant’s turbine lube oil temperature sensors suffered from electromagnetic interference (EMI) from nearby generators, causing erratic readings and 12 unplanned shutdowns annually. Post-installation, the board’s 2500Vrms isolation and noise suppression stabilized signals, eliminating shutdowns and improving lube oil temperature control accuracy by 4%. The plant’s maintenance manager noted: “The IS200TBAIH1A turned our most frustrating sensor issue into a non-problem—we haven’t touched those terminals in 6 months.”

Gulf Coast Petrochemical RefineryA refinery using GE Frame 5 turbines relied on outdated terminal boards for fuel gas pressure monitoring, leading to 3% fuel waste due to inaccurate flow control. Integrating the GE IS200TBAIH1A synchronized pressure signal acquisition with the Mark VI controller, cutting fuel consumption by 2.2% and saving $78,000 annually. Its compatibility with the refinery’s existing IS220PAICH1A module also avoided $15,000 in system reconfiguration costs.

Related Product Combination Solutions

IS220PAICH1A: GE Mark VI analog I/O pack – Acts as the upstream processing unit for the IS200TBAIH1A, converting conditioned analog signals into digital data for the controller .

IS200TPSAG1A: GE Mark VI redundant power supply – Provides stable 24V DC to the IS200TBAIH1A, preventing signal loss during grid fluctuations .

IS200TDBGH1A: GE Mark VI data logging module – Captures sensor data from the IS200TBAIH1A for trend analysis and predictive maintenance of turbine components.

IS200TCCAG1B: GE Mark VI communication interface – Transmits filtered signals from the IS200TBAIH1A to third-party DCS systems (e.g., Honeywell Experion) via Modbus RTU .

IS200TBAOH1A: GE analog output terminal board – Complements the IS200TBAIH1A by handling actuator control signals, creating a full analog I/O termination solution .

IS200SSCAH1A: GE control circuit board – Works with the IS200TBAIH1A to optimize signal routing in complex Mark VI systems .

IS200STAIH2A: GE analog input control board – Serves as a high-density alternative to the IS200TBAIH1A for systems requiring more than 10 input channels .

Installation, Maintenance, and Full-Cycle Support

Installing the IS200TBAIH1A is streamlined: it mounts directly to 19-inch Mark VI racks and connects to I/O modules via three rear connectors (JT1, JS1, JR1) . Wiring is simplified by labeled terminal blocks, and pre-installation checks only require verifying system compatibility with Mark VI software v6.0+ and using ESD-safe tools to protect components.

Routine maintenance takes under 20 minutes monthly: inspect terminal block seating, clean connector ports to prevent dust buildup, and verify potentiometer settings. Faults are easy to isolate—signal loss or drift triggers controller alarms linked to specific channels, and the pluggable terminals allow hot-swapping the IS200TBAIH1A in 15 minutes without system shutdowns .

GE backs the IS200TBAIH1A with 24/7 technical support and a 1-year warranty . Customers also gain access to detailed wiring diagrams and calibration guides. For complex installations, GE offers on-site commissioning to ensure optimal signal performance and system integration.