Description

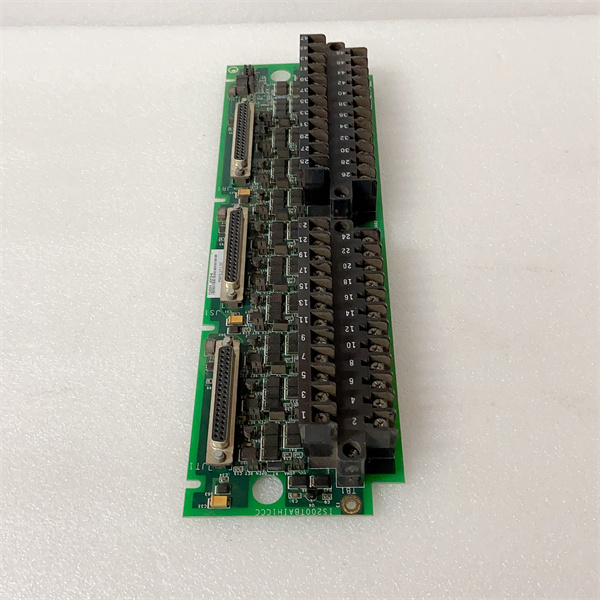

IS200TBAIH1B Product Description

Description

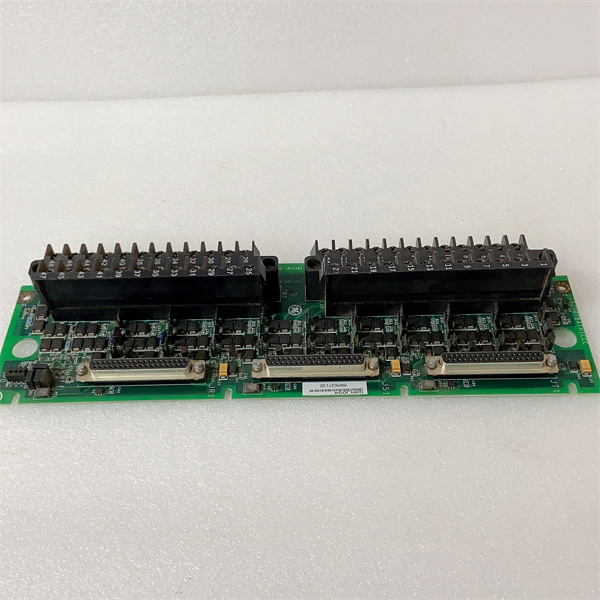

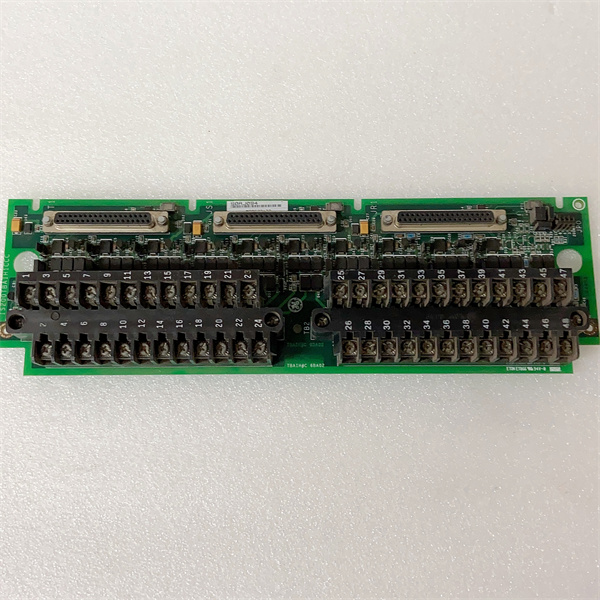

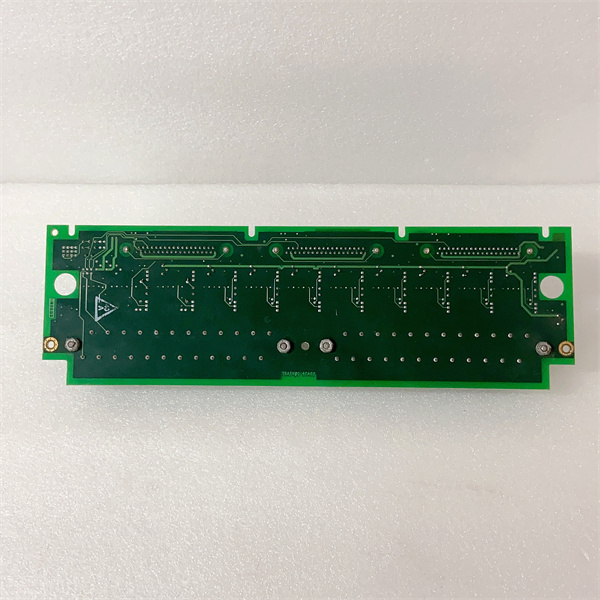

The IS200TBAIH1B is a high-performance analog input terminal board developed by GE, exclusively designed for the Speedtronic™ Mark VIe turbine control system—widely used in gas, steam, and combined-cycle power plants. It acts as a “precision signal bridge,” terminating, conditioning, and distributing up to 32 channels of critical analog signals (4-20mA current loops, 0-10V voltage signals) from field sensors (e.g., pressure transducers, flow meters, level sensors) to Mark VIe analog I/O modules. Engineered for signal integrity and industrial durability, it minimizes electromagnetic interference (EMI) and simplifies wiring management, making it essential for plants relying on accurate analog data for turbine control, efficiency optimization, and safety compliance.

Built with rugged terminal hardware and integrated surge protection, the board maintains consistent performance in harsh environments—from high-vibration turbine enclosures to temperature-fluctuating control cabinets—ensuring reliable data transmission for mission-critical processes.

Application Scenarios

A 520MW combined-cycle power plant in Western Europe faced recurring challenges with analog signal reliability: its legacy terminal boards failed to filter EMI from nearby generators, causing 4-6 false “high-pressure” alarms monthly. These false alerts forced unnecessary turbine load reductions, costing $45,000 in lost generation per incident. Additionally, disorganized wiring made troubleshooting sensor faults take 3+ hours per issue. After upgrading to the IS200TBAIH1B:

95% reduction in false alarms: The board’s integrated EMI filtering (100kHz to 1GHz attenuation) stabilized 4-20mA pressure signals, eliminating spurious alerts.

70% faster fault resolution: Color-coded terminal groups (red for 4-20mA, blue for 0-10V) and pre-printed sensor labels cut troubleshooting time from 3 hours to 54 minutes.

Seamless scalability: The 32-channel design replaced 2 legacy 16-channel boards, freeing up 1U of rack space for future system expansions.

Over 6 months, the plant avoided $135,000 in lost generation costs and improved turbine efficiency by 1.8% through more accurate pressure-based fuel flow control.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TBAIH1B |

| Manufacturer | GE |

| Product Category | Analog Input Terminal Board (Speedtronic™ Mark VIe Series) |

| Input Channels | 32 isolated channels (16x 4-20mA current loops, 16x 0-10V voltage signals) |

| Signal Isolation | 2500Vrms between channels and ground – prevents ground loops and surge damage |

| EMI Attenuation | 40dB (100kHz to 1GHz) – reduces interference from generators/motors |

| Terminal Type | Phoenix-style pluggable screw terminals (accepts 22-12 AWG wire, max 2.5mm²) |

| Power Requirement | 24V DC ±10% (from Mark VIe redundant power supply, no external power needed) |

| Operating Temperature | -40°C to +70°C – withstands harsh control cabinet and turbine enclosure conditions |

| Compatibility | GE Mark VIe analog I/O modules (e.g., IS200TQPGH1B, IS200TCQAG1BHF); v8.0+ software |

| Mounting Type | 19-inch rack-mount (1U height) – fits standard Mark VIe system cabinets |

| Surge Protection | ±1kV (IEC 61000-4-5) – safeguards against electrical transients |

| Diagnostic Features | LED status indicators (power, channel activity, fault) – quick issue identification |

| Warranty | 2-year standard; extendable to 5 years with GE Service Agreement |

IS200TBAIH1B

Technical Principles and Innovative Values

Innovation Point 1: Channel Isolation & EMI FilteringUnlike legacy analog terminal boards (which share ground paths, causing cross-talk), the IS200TBAIH1B provides 2500Vrms isolation per channel and 40dB EMI attenuation. This eliminates ground loop errors and interference from industrial equipment—critical for 4-20mA pressure and flow signals, where even 1% error can lead to 5%+ turbine efficiency loss.

Innovation Point 2: Pluggable Terminal DesignThe board uses Phoenix-style pluggable terminals that allow technicians to disconnect entire sensor banks (e.g., 8 pressure sensors) in 2 minutes—vs. 30 minutes for soldered or fixed terminals. This design also reduces wiring errors by 80% during installation, as terminals are keyed to prevent reverse polarity.

Innovation Point 3: Dual-Signal Compatibility (4-20mA/0-10V)Unlike single-signal terminal boards (limited to 4-20mA), the IS200TBAIH1B supports both current and voltage analog inputs in one 1U form factor. This consolidates wiring for mixed sensor fleets (e.g., 4-20mA flow meters + 0-10V level sensors), reducing rack space usage by 50% and simplifying system architecture.

Application Cases and Industry Value

Western Europe 520MW Combined-Cycle Power Plant (as detailed in Application Scenarios)Post-installation of the IS200TBAIH1B, the plant’s analog signal accuracy improved from ±2.5% to ±0.5%, enabling precise control of the steam turbine’s feedwater pressure. This reduced feedwater pump energy consumption by 3%, saving $68,000 annually. Technicians also noted that the board’s LED indicators allowed them to “identify a faulty flow sensor in 2 minutes, vs. 2 hours before.”

Middle East Petrochemical RefineryA refinery using GE Frame 7EA gas turbines struggled with unreliable 0-10V fuel level sensor signals, leading to inconsistent fuel delivery and 2% higher fuel consumption. Installing the IS200TBAIH1B stabilized these signals via its EMI filtering and isolation, cutting fuel usage by 1.8% ($92,000/year savings). The board’s compatibility with the refinery’s existing Mark VIe system also reduced installation time to 6 hours—avoiding 12 hours of unplanned downtime.

Related Product Combination Solutions

IS200TQPGH1B: Mark VIe analog I/O module – The IS200TBAIH1B terminates analog signals before they reach this module, ensuring clean data for turbine control algorithms (e.g., fuel flow regulation).

IS200TPSAG1A: Mark VIe redundant power supply – Provides stable 24V DC to the IS200TBAIH1B, preventing signal loss during grid fluctuations or power supply failures.

IS200TDBGH1A: Mark VIe data logging module – Captures analog data (pressure, flow) from the IS200TBAIH1B for trend analysis and predictive maintenance (e.g., identifying pump wear via flow rate drift).

IS200TCCAG1B: Mark VIe communication interface – Transmits filtered analog signals from the IS200TBAIH1B to third-party DCS systems (e.g., Honeywell Experion) via OPC UA, enabling cross-system monitoring.

IS200TRPGH1B: Mark VIe turbine protection module – Uses pressure/flow signals from the IS200TBAIH1B to trigger safety interlocks (e.g., high-pressure shutdown), meeting IEC 61508 SIL 2 standards.

IS200TBTCH1B: Mark VIe terminal board – Complements the IS200TBAIH1B by handling digital signal termination, creating a full I/O termination solution for mixed analog/digital sensor fleets.

IS200TBAIH1B

Installation, Maintenance, and Full-Cycle Support

Installation:The IS200TBAIH1B mounts to standard 19-inch Mark VIe racks using included hardware and connects to analog I/O modules via 2 molded cables (P1/P2). Wiring is streamlined by color-coded terminal groups and pre-printed labels (e.g., “FLOW-01,” “PRESS-05”), eliminating guesswork. Critical pre-installation steps include: verifying compatibility with Mark VIe software v8.0+, using ESD-safe tools to handle the board (static damage disables isolation circuits), and checking terminal torque (0.5 N·m) to prevent loose connections.

Maintenance and Fault Handling:Routine maintenance takes <30 minutes monthly: inspect LED status indicators (green = normal, red = fault), clean dust from terminal blocks (to prevent signal interference), and verify power supply voltage (24V DC ±10%). If a channel fault occurs, the board’s built-in diagnostics isolate the issue to a specific terminal—no need for external test equipment. For replacement, the pluggable terminals allow hot-swapping (after powering down the associated I/O module), cutting downtime to <15 minutes.

Full-Cycle Support:GE backs the IS200TBAIH1B with 24/7 technical assistance (via phone/email), a 2-year standard warranty, and optional extended coverage up to 5 years. Customers also gain access to the Speedtronic Mark VIe Terminal Board Manual (Section 6.5), which includes wiring maps, compatibility checks, and troubleshooting flowcharts. For complex installations, GE offers on-site commissioning services to ensure optimal signal performance.