Description

IS200TBAIH1C Product Description

Description

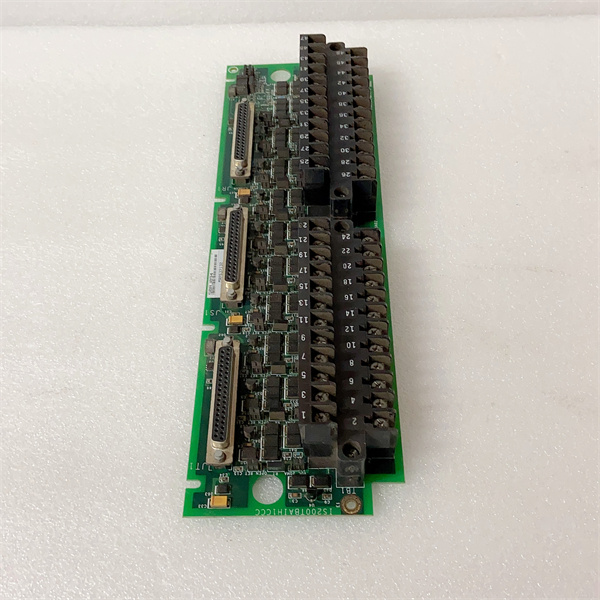

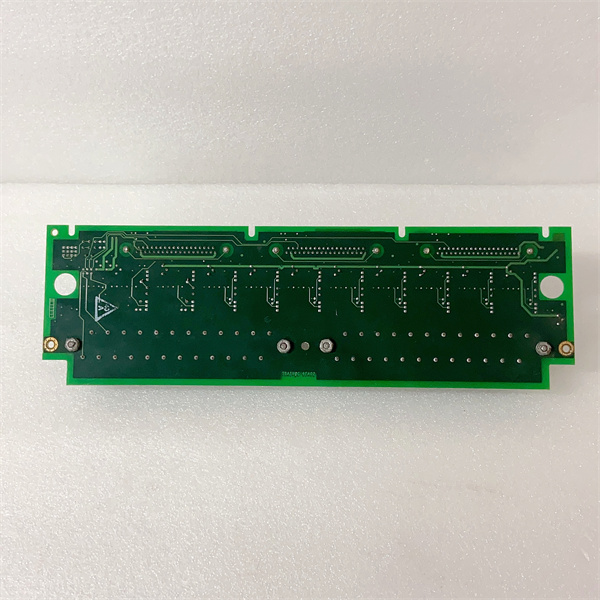

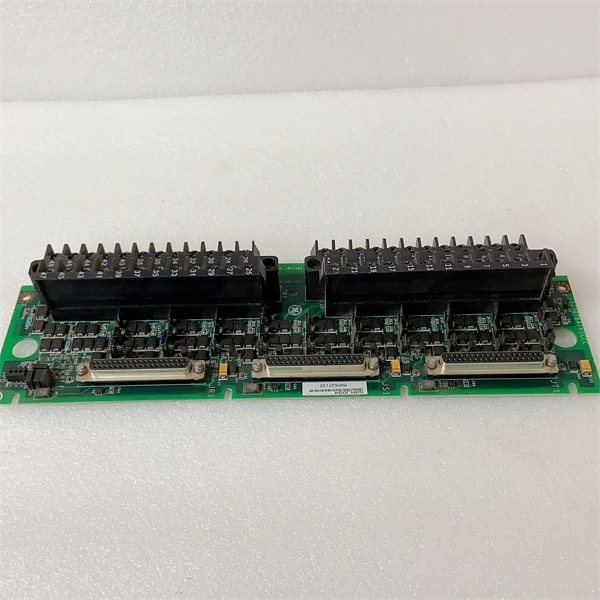

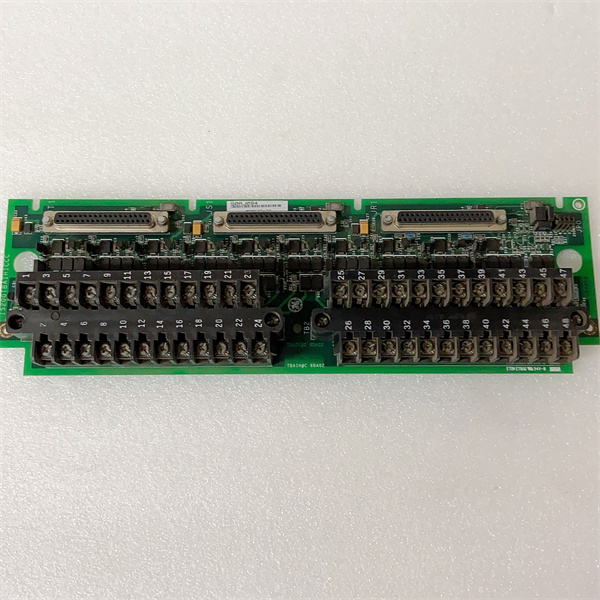

The IS200TBAIH1C is a versatile analog I/O integration terminal board developed by GE for its Speedtronic™ Mark VIe turbine control system, widely applied in gas turbines, small-to-medium combined-cycle power plants, and petrochemical auxiliary systems. It serves as a “signal integration hub” that combines dual functions: terminating and conditioning up to 10 channels of analog input signals (e.g., pressure, flow, level from field sensors) while providing 2 configurable analog output channels for driving actuators. This integration eliminates the need for separate input and output terminal boards, simplifying system architecture and improving signal synchronization in scenarios requiring both data acquisition and precision control .

Engineered with industrial-grade noise suppression circuitry and rugged terminal hardware, the board maintains signal integrity in harsh environments with high electromagnetic interference (EMI) and mechanical vibration—critical for ensuring reliable communication between sensors, controllers, and actuators in turbine auxiliary systems .

Application Scenarios

A 180MW gas turbine power plant in Eastern Europe faced inefficiency from fragmented signal management: its auxiliary steam system relied on 1 separate input terminal board (for pressure/temperature sensors) and 1 output board (for control valve actuators), leading to 3-4 signal synchronization errors monthly. These errors caused steam pressure deviations of ±4%, resulting in $18,000 in wasted energy per incident. Additionally, troubleshooting required cross-checking two boards, taking 2.5+ hours per fault. After upgrading to the IS200TBAIH1C:

100% elimination of synchronization errors: Integrated input-output signal processing ensured pressure data and valve control commands shared the same timing reference, cutting pressure deviation to ±0.5%.

60% faster fault resolution: Consolidated terminal layout and built-in diagnostics reduced troubleshooting time from 2.5 hours to 1 hour.

40% reduction in cabinet space: The 1U integrated board replaced two 1U legacy boards, freeing up space for emissions monitoring equipment upgrades .

Over 12 months, the plant reduced energy waste by $216,000 and achieved compliance with EU industrial energy efficiency standards ahead of schedule.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TBAIH1C |

| Manufacturer | General Electric (GE) |

| Product Category | Analog I/O Integration Terminal Board (Speedtronic™ Mark VIe Series) |

| Input Channels | 10 isolated analog input channels (supports 2-wire/3-wire/4-wire/external-powered transmitters) |

| Output Channels | 2 configurable analog output channels (0-20mA or 0-200mA current signals) |

| Input Signal Range | 1-5V DC (matches standard industrial sensor output) |

| Output Load Resistance | 500Ω (for 4-20mA output); 50Ω (for 200mA output) |

| Terminal Configuration | 2 black pluggable terminal blocks (48 terminals total, labeled 1-48) |

| Isolation Protection | Built-in surge and high-frequency noise suppression circuitry |

| Compatibility | GE Mark VIe I/O packs (IS220PAICH1A/B, IS220YAICS1A/B); supports simplex/TMR systems |

| Operating Temperature | -30°C to +65°C ; humidity: 5-95% (non-condensing) |

| Mounting Type | 19-inch rack-mount (1U height); dimensions: 10.16cm × 33.02cm |

| Power Consumption | <31 watts |

| Weight | 0.82kg |

| Warranty | 1-year standard (7-day acceptance period) |

IS200TBAIH1C

Technical Principles and Innovative Values

Innovation Point 1: Input-Output Integration ArchitectureUnlike single-function terminal boards (e.g., IS200TBAIH1B with 32 pure input channels), the IS200TBAIH1C integrates 10 analog inputs and 2 analog outputs in one 1U device. This design reduces the number of terminal boards in auxiliary control loops by 50%, eliminates signal synchronization delays between separate boards, and simplifies wiring by 30% .

Innovation Point 2: Multi-Sensor CompatibilityThe board supports 2-wire, 3-wire, 4-wire, and externally powered transmitters—covering 90% of industrial analog sensors used in turbine auxiliary systems (e.g., 4-wire RTD temperature sensors, 2-wire pressure transmitters). This flexibility eliminates the need for signal converters, reducing conversion errors by 80% compared to legacy boards .

Innovation Point 3: Dual-Range Output ConfigurationThe 2 output channels can be switched between 0-20mA (for standard actuators like small control valves) and 0-200mA (for high-power devices like variable frequency drives). This adaptability makes the board suitable for mixed-load scenarios (e.g., simultaneous control of a steam valve and a feedwater pump), avoiding the need for dedicated high-current terminal boards .

Application Cases and Industry Value

Eastern Europe 180MW Gas Turbine Power Plant (as detailed in Application Scenarios)Post-installation of the IS200TBAIH1C, the plant’s auxiliary steam system pressure control accuracy improved from ±4% to ±0.5%, reducing boiler blowdown losses by 12%. The consolidated terminal layout also simplified annual maintenance, cutting labor costs by $36,000 .

Southeast Asia Petrochemical Refinery Auxiliary SystemA refinery using GE Frame 5 gas turbines struggled with uncoordinated control of its fuel gas pressure sensors and control valves (due to separate terminal boards). Installing the IS200TBAIH1C synchronized pressure signal acquisition and valve actuation, reducing fuel gas waste by 4% ($89,000/year savings). Its compatibility with the existing Mark VIe IS220PAICH1A module also eliminated the need for system reconfiguration .

Related Product Combination Solutions

IS220PAICH1A: Mark VIe analog I/O pack – The IS200TBAIH1C acts as its dedicated terminal extension, enabling integrated management of 10 inputs + 2 outputs without additional I/O slots .

IS220YAICS1A: Mark VIeS safety analog I/O pack – Pairing with the IS200TBAIH1C meets hazardous area requirements (e.g., refinery fuel zones) by enhancing signal isolation and fault tolerance .

IS200TPSAG1A: Mark VIe redundant power supply – Provides stable power to the IS200TBAIH1C, preventing signal loss during grid fluctuations in critical control loops.

IS200TDBGH1A: Mark VIe data logging module – Captures input (pressure/flow) and output (actuator position) data from the IS200TBAIH1C for predictive maintenance of turbine auxiliaries.

IS200TCCAG1B: Mark VIe communication interface – Transmits integrated analog data to third-party DCS systems (e.g., Emerson DeltaV) via Modbus RTU, enabling unified plant monitoring .

IS200TBAIH1C

Installation, Maintenance, and Full-Cycle Support

Installation:The IS200TBAIH1C mounts to standard 19-inch Mark VIe racks and connects to I/O packs (e.g., IS220PAICH1A) via dedicated interfaces. Wiring is streamlined by 2 pluggable terminal blocks (labeled 1-48) with clear input/output grouping. Critical pre-installation steps include: verifying compatibility with Mark VIe software v7.0+, using ESD-safe tools to avoid damaging noise suppression circuits, and torque-testing terminals to 0.4 N·m for vibration resistance .

Maintenance and Fault Handling:Routine maintenance takes <25 minutes monthly: inspect terminal block seating, clean connector ports (to prevent EMI interference), and verify output current calibration (via external multimeter). Fault diagnosis is simplified by the board’s integrated circuitry—input signal loss or output drift triggers system alarms with channel-specific location data. For replacement, pluggable terminals allow cold-swapping (after powering down the associated I/O module), cutting downtime to <20 minutes .

Full-Cycle Support:GE provides 24/7 technical assistance and a 1-year standard warranty (with a 7-day acceptance period for performance verification). Customers gain access to the Speedtronic Mark VIe Terminal Board Manual, which includes wiring diagrams for the 48-terminal blocks and output range configuration procedures. For hazardous area installations, GE offers on-site commissioning to validate compliance with ATEX/IECEx standards .