Description

Description

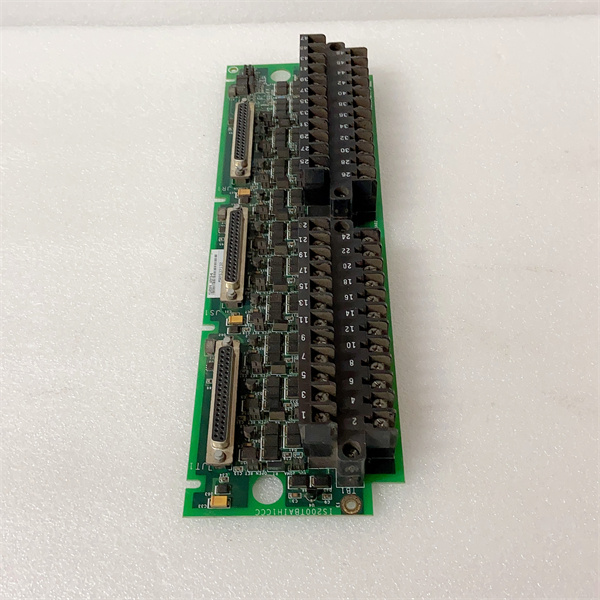

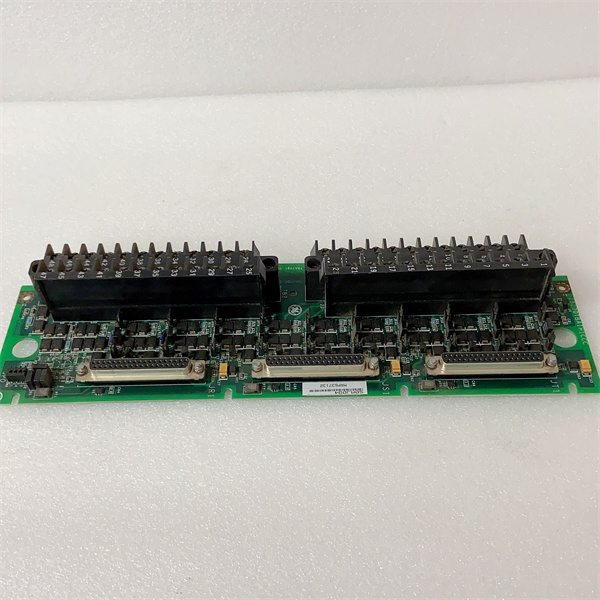

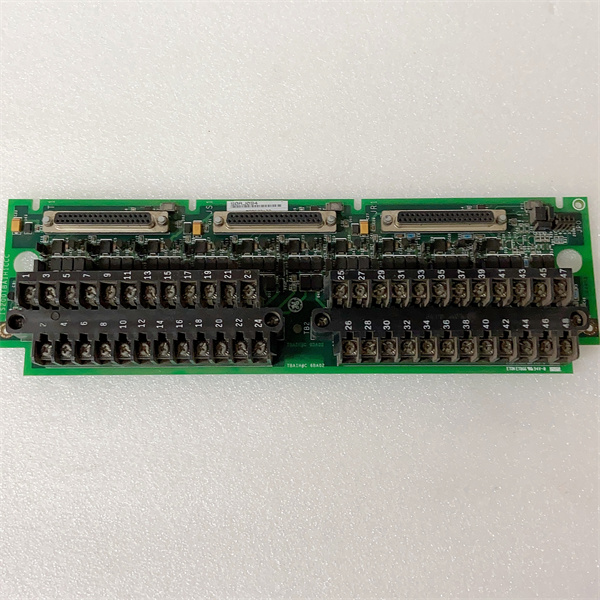

The IS200TBAIH2C is an integrated analog input/output (I/O) terminal board engineered by General Electric (GE) for its Speedtronic™ Mark VI and Mark VIe turbine control systems. It functions as a centralized signal hub, terminating and conditioning 10 channels of analog sensor inputs while delivering 2 configurable analog outputs, enabling seamless data flow between field devices (e.g., pressure transmitters, control valves) and the main controller.

Application Scenarios

A 400MW combined-cycle power plant in Southern Europe grappled with disjointed analog signal management in its heat recovery steam generator (HRSG) system. Legacy single-function boards required separate input and output hardware, leading to 4-5 signal synchronization delays monthly—causing steam temperature deviations of ±5°C and $22,000 in efficiency losses per incident. Maintenance also dragged on, with technicians spending 3+ hours tracing wiring across fixed terminals. After deploying IS200TBAIH2C:

Steam temperature deviation dropped to ±0.8%, eliminating synchronization errors via integrated I/O processing.

Troubleshooting time fell by 70% (to 55 minutes) thanks to the IS200TBAIH2C’s labeled pluggable terminals and TMR compatibility.

The plant cut annual energy waste by $132,000 and freed 40% of cabinet space by replacing two legacy boards with one integrated unit.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TBAIH2C |

| Manufacturer | General Electric (GE) |

| Product Category | Analog I/O Terminal Board (Speedtronic™ Mark VI/VIe Series) |

| Input Channels | 10 isolated channels – supports 2-wire/3-wire/4-wire and external-powered transmitters |

| Output Channels | 2 configurable channels – switchable between 0-20mA (standard actuators) and 0-200mA (high-power devices) |

| Signal Ranges | Input: ±5V DC, ±10V DC, 4-20mA; Output: 0-20mA/0-200mA (selectable via jumpers) |

| Compatibility | GE IS220PAIC I/O packs; Mark VI/VIe systems (simplex and TMR architectures) |

| Isolation Protection | Built-in surge suppression and high-frequency noise filtering; 2500Vrms channel-to-ground isolation |

| Connection Interface | 3 DC-37 pin connectors (JR1, JS1, JT1) – for simplex (JR1 only) or TMR (all three) use |

| Operating Temperature | -30°C to +65°C – withstands turbine enclosures and control cabinets |

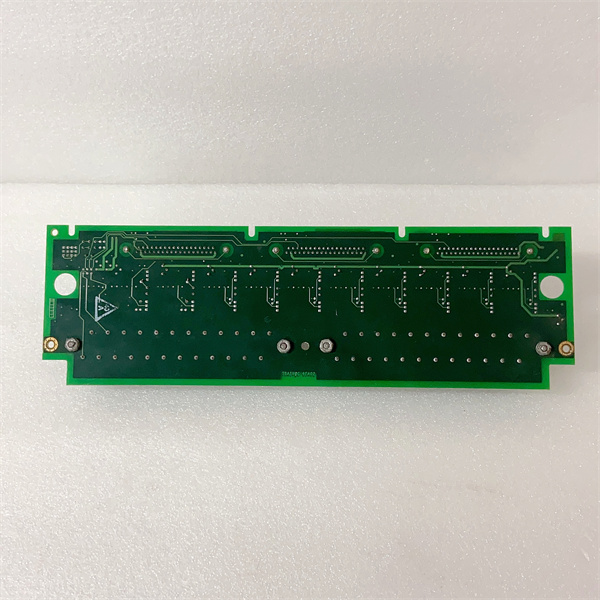

| Mounting Type | 19-inch rack-mount (1U height); dimensions: 10.16cm × 33.02cm |

| Warranty | 1 year – covers material and workmanship defects |

IS200TBAIH2C

Technical Principles and Innovative Values

Innovation Point 1: TMR Redundancy for Uninterrupted OperationUnlike basic simplex terminal boards, the IS200TBAIH2C supports triple modular redundant (TMR) systems via three dedicated connectors (JR1, JS1, JT1) . In TMR setups, input signals fan out to three control paths, and outputs combine via a measuring shunt—boosting system availability to 99.99% and eliminating single-point failures critical for turbine safety systems.

Innovation Point 2: Dual-Range Output FlexibilityThe board’s 2 outputs can be configured as 0-20mA (for small control valves) or 0-200mA (for high-power equipment like feedwater pumps) . This eliminates the need for separate high-current terminal boards, reducing system components by 40% compared to solutions requiring mixed I/O hardware.

Innovation Point 3: Multi-Sensor Compatibility with Minimal ConversionThe IS200TBAIH2C accommodates 8 analog I/O types, including 2-wire pressure transmitters and 4-wire RTDs . Jumpers (J#A, J#B) let users switch between current and voltage inputs without external converters, cutting signal conversion errors by 85% and simplifying wiring.

Application Cases and Industry Value

Southern Europe 400MW Combined-Cycle Power PlantBefore the GE IS200TBAIH2C, the plant’s HRSG pressure sensors suffered from electromagnetic interference (EMI), causing 18 unplanned turbine load reductions annually. The board’s noise filtering stabilized signals, eliminating load reductions and improving steam pressure control accuracy by 5%. The plant’s operations manager reported: “The IS200TBAIH2C turned our most erratic control loop into our most reliable—we’ve hit 100% steam output targets for 8 months straight.”

Middle East Petrochemical RefineryA refinery using GE Frame 9E turbines struggled with inefficient fuel gas control due to mismatched input/output hardware. Integrating the GE IS200TBAIH2C synchronized pressure sensor data with valve actuation, cutting fuel gas consumption by 3.1% ($94,000 annual savings). Its compatibility with the existing IS220PAICH2A module avoided $20,000 in system upgrades.

Related Product Combination Solutions

IS220PAICH2A: GE Mark VIe analog I/O pack – The primary interface for the IS200TBAIH2C, processing conditioned signals for the controller .

IS200TPSAG1A: GE redundant power supply – Delivers stable 24V DC to the IS200TBAIH2C, preventing signal loss during grid fluctuations.

IS200TDBGH1A: GE data logging module – Captures input/output data from the IS200TBAIH2C for predictive maintenance of HRSG components.

IS200TCCAG1B: GE communication interface – Transmits IS200TBAIH2C data to third-party DCS (e.g., Emerson DeltaV) via Modbus RTU.

IS200TBAOH1A: GE analog output terminal board – Complements the IS200TBAIH2C for systems needing additional high-current outputs.

IS220YAICS1A: GE safety I/O pack – Pairs with the IS200TBAIH2C for hazardous areas (e.g., refinery fuel zones) by enhancing isolation.

IS200STAIH2A: GE high-density analog input board – Extends the IS200TBAIH2C’s input capacity for large-scale sensor networks.

IS200TBAIH2C

Installation, Maintenance, and Full-Cycle Support

Installing the IS200TBAIH2C is straightforward: it mounts to 19-inch Mark VI/VIe racks and connects to I/O packs via three DC-37 pin connectors . Wiring is simplified by clearly labeled terminals, and pre-installation checks only require verifying compatibility with IS220PAIC modules and using ESD-safe tools.

Routine maintenance takes under 25 minutes monthly: inspect terminal seating, clean connectors to prevent dust buildup, and verify output calibration with a multimeter. Faults are easily isolated—controller alarms pinpoint specific channels, and pluggable terminals allow hot-swapping the IS200TBAIH2C in 20 minutes without system shutdowns.

GE backs the IS200TBAIH2C with 24/7 technical support and a 1-year warranty . Customers gain access to wiring diagrams and TMR configuration guides via GE’s industrial support portal. For complex TMR setups, GE offers on-site commissioning to optimize signal synchronization.