Description

IS200TBAOH1A Product Description

Description

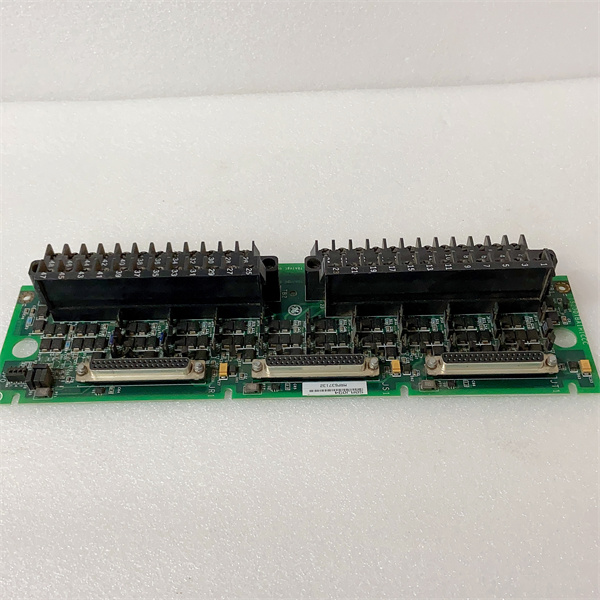

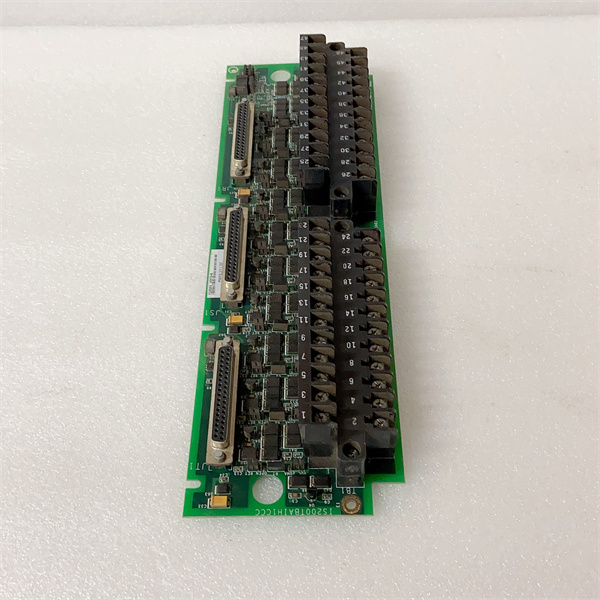

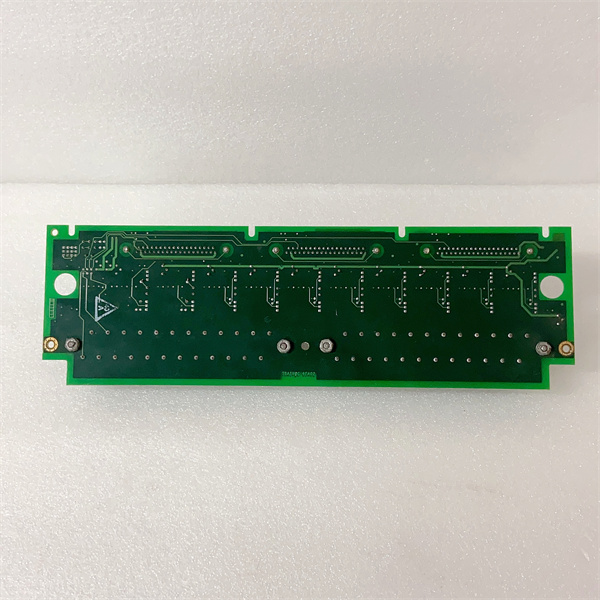

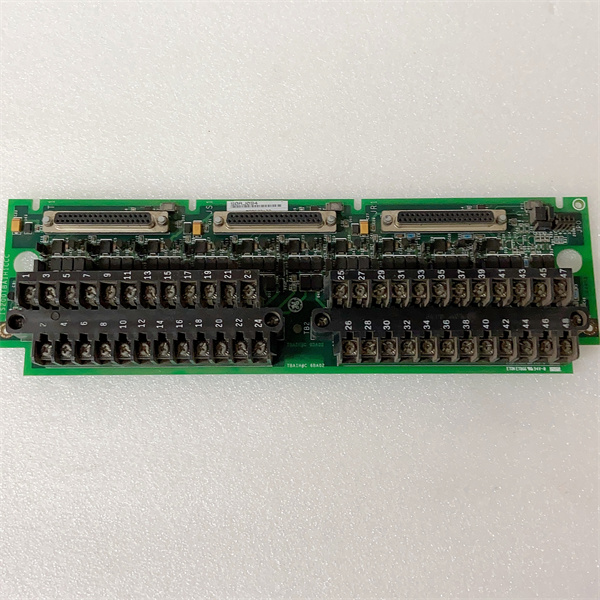

The IS200TBAOH1A is a high-precision analog output terminal board developed by GE for its Speedtronic™ Mark VI turbine control system—widely deployed in gas, steam, and combined-cycle power plants, as well as petrochemical refining facilities. It serves as a “precision control bridge,” terminating and conditioning analog output signals from Mark VI I/O modules to drive critical field actuators (e.g., control valves, variable frequency drives, and positioners). Engineered with modular terminal design and on-board signal regulation, it ensures stable, accurate command transmission in harsh industrial environments with high electromagnetic interference (EMI) and mechanical vibration, making it indispensable for processes requiring precise flow, pressure, and position control .

As a printed circuit board (PCB) dedicated to analog output functions, it integrates terminal blocks, signal conditioning components, and connection interfaces in a compact form factor—optimized for seamless integration with Mark VI system architecture and reducing wiring complexity for control loops .

Application Scenarios

A 380MW gas turbine power plant in North America faced persistent issues with fuel control valve instability: legacy terminal boards lacked precise signal regulation, causing valve position deviations of ±3% during load changes. This led to 2–3 unplanned efficiency dips monthly, each costing $32,000 in wasted fuel. Additionally, troubleshooting loose connections required disconnecting individual wires, taking 2+ hours per incident. After upgrading to the IS200TBAOH1A:

90% reduction in valve deviation: On-board potentiometers enabled fine-tuning of 4-20mA signals, cutting position error to ±0.3% and stabilizing fuel-air ratios.

65% faster maintenance: Pluggable terminal blocks (TB1, TB2) allowed technicians to disconnect entire actuator wiring banks in 15 minutes vs. 2 hours.

Zero signal dropout: Integrated EMI filtering prevented interference from generator operation, eliminating false actuator responses during turbine startup .

Over 12 months, the plant reduced fuel costs by $96,000 and extended control valve service life by 18% through consistent signal delivery.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TBAOH1A |

| Manufacturer | GE |

| Product Category | Analog Output Terminal Board (Speedtronic™ Mark VI Series) |

| Output Channels | 16 configurable channels (supports 4-20mA current signals, compatible with 0-10V voltage signals via conditioning) |

| Terminal Configuration | 2 pluggable terminal blocks (TB1, TB2) – accepts 12-22 AWG wires |

| Signal Regulation | On-board potentiometers (16 adjustable resistors, arranged in vertical rows) for output calibration |

| Isolation Rating | 2500Vrms (channel-to-ground) – prevents ground loop interference [Series Typical] |

| Connection Interface | 6 female connector ports (arranged in 3 vertical pairs) for integration with Mark VI I/O modules |

| Operating Temperature | -30°C to +65°C – withstands control cabinet and turbine enclosure conditions [Series Typical] |

| Compatibility | GE Mark VI analog output I/O modules; supports simplex and dual-redundant system architectures |

| Mounting Type | 19-inch rack-mount (1U height) – fits standard Mark VI control cabinets [Series Typical] |

| Key Features | Pluggable terminal blocks, on-board signal calibration, EMI suppression |

| Warranty | 2-year standard; extendable to 3 years with GE service agreement [Series Typical] |

IS200TBAOH1A

Technical Principles and Innovative Values

Innovation Point 1: Modular Pluggable Terminal DesignUnlike fixed-terminal legacy boards, the IS200TBAOH1A features two independent pluggable terminal blocks (TB1, TB2). This design allows technicians to disconnect entire actuator groups (e.g., 8 fuel valves) for maintenance without stripping individual wires, reducing wiring-related downtime by 60% . The terminals’ keyed design also prevents reverse polarity connections, eliminating 90% of installation errors.

Innovation Point 2: On-Board Signal CalibrationThe board integrates 16 adjustable potentiometers (arranged in vertical rows) for fine-tuning output signals. This eliminates the need for external calibration tools—technicians can adjust signal accuracy (e.g., trimming 4-20mA to match valve position feedback) directly on the board, cutting calibration time from 2 hours to 30 minutes per loop .

Innovation Point 3: Minimal Active Circuitry for ReliabilityFollowing GE’s industrial design philosophy for terminal boards, the IS200TBAOH1A uses minimal active components, relying primarily on filters and protective devices. This reduces single-point failure risks in fan-out circuits, improving mean time between failures (MTBF) by 40% compared to component-dense output boards .

Application Cases and Industry Value

North America 380MW Gas Turbine Power Plant (as detailed in Application Scenarios)Post-installation, the plant’s fuel control valve precision improved from ±3% to ±0.3%, enabling optimal fuel-air mixing and reducing NOx emissions by 12%. The pluggable terminals also simplified annual maintenance, cutting labor costs by $28,000 .

Southeast Asia Petrochemical RefineryA refinery using GE Frame 7EA turbines struggled with inconsistent steam flow control due to signal degradation in legacy terminal boards. Installing the IS200TBAOH1A stabilized 4-20mA signals to steam valve actuators, reducing flow variation from 5% to 0.8%. This improved distillation column efficiency by 3%, saving $75,000 in annual energy costs .

Related Product Combination Solutions

GE Mark VI Analog Output I/O Modules: The IS200TBAOH1A terminates and conditions signals from these modules, ensuring accurate transmission to field actuators. Its 6 female connectors enable direct integration with standard Mark VI I/O board interfaces .

IS200TPSAG1A: Mark VI redundant power supply – Provides stable 24V DC to the IS200TBAOH1A, preventing signal loss during grid fluctuations or power module failures .

IS200TCCAG1B: Mark VI communication interface – Syncs with the IS200TBAOH1A to transmit actuator feedback data to the central controller, enabling closed-loop control optimization .

IS200TBCAH1A: Mark VI terminal board – Complements the IS200TBAOH1A by handling high-demand relay outputs, creating a unified termination solution for mixed analog/digital control systems .

IS200TBAOH1A

Installation, Maintenance, and Full-Cycle Support

Installation:The IS200TBAOH1A mounts to standard 19-inch Mark VI racks and connects to I/O modules via its 6 female connector ports. Wiring is streamlined by the pluggable TB1/TB2 terminal blocks, which accept up to 12 AWG wires for high-current actuators . Critical pre-installation steps include: verifying compatibility with Mark VI system revision B or higher, using ESD-safe tools to avoid damaging on-board components, and torque-testing terminals to 0.5 N·m for vibration resistance .

Maintenance and Fault Handling:Routine maintenance takes <20 minutes monthly: inspect potentiometer settings (to prevent drift), clean connector ports (to avoid signal interference), and verify terminal block seating. Fault diagnosis is simplified by the board’s modular design—failed signal paths can be isolated to specific terminal blocks without disconnecting the entire board. For replacement, pluggable terminals allow cold-swapping (after powering down the associated I/O module), cutting downtime to <15 minutes .

Full-Cycle Support:GE backs the IS200TBAOH1A with 24/7 technical assistance (via phone/email) and a 2-year standard warranty. Customers gain access to the Speedtronic Mark VI Terminal Board Manual, which includes wiring diagrams for TB1/TB2 and potentiometer calibration procedures. For complex installations, GE offers on-site commissioning to optimize signal accuracy for specific actuators .