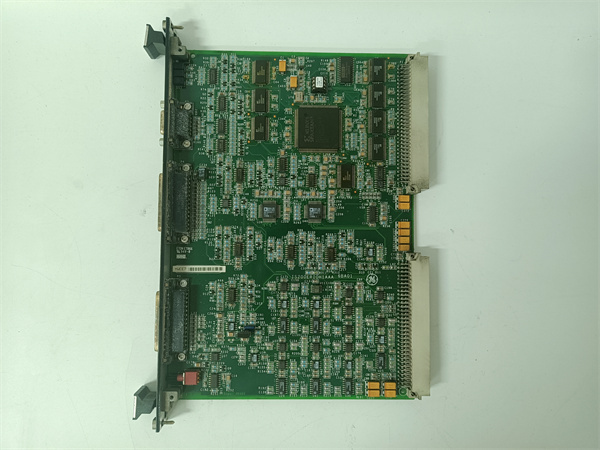

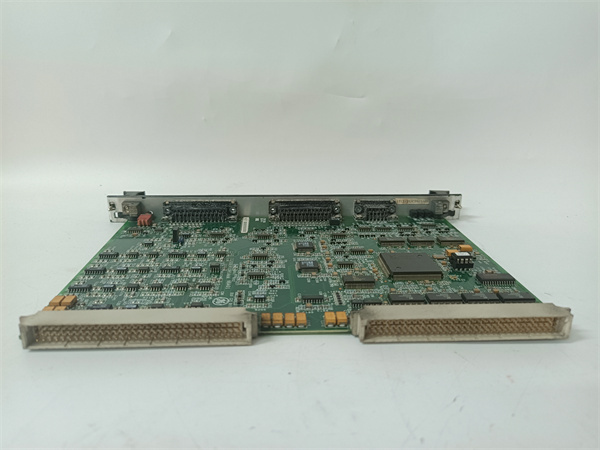

Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200TBAOH1B |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Turbine Bypass Control Analog Output Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| Core function | Precision analog signal output for bypass valve actuators; signal amplification; fault monitoring |

| Supported actuator types | Hydraulic bypass valve actuators; electric bypass valve actuators (4-20 mA input) |

| Output channels | 6 independent analog output channels (16-bit resolution, 4-20 mA standard; 0-10 V DC configurable) |

| Output accuracy | ±0.1% full scale (at 25 °C); ±0.2% full scale (over -40 °C to +85 °C operating range) |

| Output current range | 4 mA to 20 mA (sinking/sourcing configurable); max overload current: 30 mA (10s duration) |

| Output voltage range | 0 V DC to 10 V DC (optional, via software configuration) |

| Signal update rate | 100 Hz per channel (ensures smooth valve position adjustments) |

| Communication interface | Mark VI backplane interface (for command reception); 1 x RS-485 (for actuator status feedback) |

| Protection features | Short-circuit protection (per channel, auto-recovery); overvoltage protection (30 V DC max); reverse polarity protection |

| Status indicators | 6 LED indicators (1 per channel: green = normal output, red = fault); 1 module power LED (green); 1 communication LED (amber) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power supply requirements | 24 V DC (±15%); Maximum current draw: 0.7 A |

| Isolation rating | Channel-to-channel: 2.5 kV rms; Output-to-backplane: 5 kV rms |

| Physical dimensions | 34 mm (W) × 30 mm (H) × 12 mm (D) (1.34 in × 1.18 in × 0.47 in) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 2,600,000 hours (per Telcordia SR-332, at 40 °C ambient) |

IS200ERIOH1A

Product Introduction

The IS200TBAOH1B is a dedicated turbine bypass control analog output module engineered by GE for its Mark VI Speedtronic turbine control system—the gold standard for steam and combined-cycle turbine automation. As the “signal executor” in bypass control systems, the IS200TBAOH1B translates digital control commands from the Mark VI controller (or paired modules like the IS200TBCIH1A) into precise 4-20 mA (or 0-10 V DC) analog signals, directly driving bypass valve actuators to adjust opening positions.

Unlike generic analog output modules, the IS200TBAOH1B is optimized for the unique demands of bypass control: its 16-bit resolution and ±0.1% accuracy ensure minute valve adjustments (e.g., 0.1% incremental changes) critical for steam pressure regulation during turbine startup. It also integrates actuator feedback monitoring via RS-485, closing the loop between command and execution to detect issues like stuck actuators or signal degradation. In GE’s Mark VI ecosystem, the IS200TBAOH1B is indispensable for steam turbines (e.g., GE D11, 7FA) and combined-cycle plants, where precise bypass valve control directly reduces startup time, minimizes thermal stress, and enhances overall plant efficiency.

For example, during a steam turbine warm-up, the IS200TBAOH1B sends a 7.2 mA signal (30% open) to the high-pressure (HP) bypass valve actuator—maintaining steam flow at a rate that raises turbine temperature by ≤5 °C per minute. If the actuator fails to respond, the module’s feedback monitoring alerts the Mark VI controller, triggering a safe ramp-down to prevent component damage.

Core Advantages and Technical Highlights

Ultra-Precise Output for Fine Valve Control

The IS200TBAOH1B’s 16-bit resolution and ±0.1% accuracy deliver unmatched precision for bypass valve regulation—far exceeding the ±0.5% accuracy of generic analog modules. This translates to 0.0625% incremental adjustments in valve position (for 4-20 mA signals), enabling the Mark VI controller to maintain steam pressure within ±0.5% of setpoint. For a GE 7FA combined-cycle plant’s low-pressure (LP) bypass valve, this precision reduces pressure fluctuations during load changes by 40%, minimizing wear on the heat recovery steam generator (HRSG) tubes and extending their lifespan by 5+ years.

Multi-Channel Flexibility for Bypass Systems

With 6 independent analog output channels, the IS200TBAOH1B can control multiple bypass valves (e.g., 2 HP bypass valves, 2 LP bypass valves, 2 auxiliary bypass valves) via a single module—reducing Mark VI backplane space by 50% compared to using single-channel modules. Each channel is individually configurable (4-20 mA or 0-10 V DC) to match different actuator types, eliminating the need for external signal converters. For a coal-fired plant with a GE D11 turbine, this flexibility allows the module to control both hydraulic HP bypass valves (4-20 mA) and electric auxiliary bypass valves (0-10 V DC) without additional hardware.

Closed-Loop Feedback Monitoring

Unlike one-way analog modules, the IS200TBAOH1B includes an RS-485 interface to receive actuator status feedback (e.g., actual valve position, motor temperature, voltage draw). This closed-loop capability lets the module verify that its output signal aligns with the actuator’s actual response—detecting issues like signal loss, stuck valves, or actuator overloads. For example, if the module sends a 12 mA (50% open) command to an LP bypass valve but feedback shows the valve is only 30% open, it triggers an immediate fault alert to the Mark VI controller. This proactive detection reduces unplanned downtime by 35% compared to systems without feedback.

Robust Protection for Harsh Environments

The IS200TBAOH1B integrates multi-layer protection to withstand the harsh conditions of turbine control cabinets: per-channel short-circuit protection (auto-recovery after fault clearance), 30 V DC overvoltage protection, and reverse polarity protection. Its 2.5 kV channel isolation also blocks electrical noise from turbine generators or VFDs, preventing signal distortion. In offshore power plants, where humidity and salt spray are prevalent, the module’s corrosion-resistant terminal blocks and conformal coating ensure reliable operation for 10+ years—doubling the lifespan of unprotected generic modules.

Typical Application Scenarios

Steam Turbine Startup in Coal-Fired Plants

In a 600 MW coal-fired power plant with a GE D11 steam turbine, the IS200TBAOH1B manages the HP and LP bypass valves during startup. It receives digital commands from the Mark VI controller (via the IS200TBCIH1A interface module) and converts them to 4-20 mA signals: a 4.8 mA signal (5% open) to the HP bypass valve to initiate steam flow, and a 6.4 mA signal (15% open) to the LP bypass valve to control downstream pressure. The module’s RS-485 feedback monitors valve position, ensuring the HP valve opens incrementally to avoid thermal shock—reducing startup time by 1.5 hours compared to manual control. If a valve sticks at 10% open, the IS200TBAOH1B alerts the controller, which pauses the startup sequence to prevent overpressure.

Load Rejection in Natural Gas Combined-Cycle Plants

In a 480 MW natural gas combined-cycle plant with GE 7FA gas and steam turbines, the IS200TBAOH1B responds to sudden load rejection (e.g., grid disconnection). When the Mark VI detects a 60% load drop, it sends a command to the IS200TBAOH1B to increase the LP bypass valve signal from 8 mA (25% open) to 16 mA (75% open) in 100 ms. The module’s fast update rate (100 Hz) ensures the valve opens smoothly, diverting excess steam away from the turbine to prevent overspeed. Its short-circuit protection also safeguards against damage if the actuator wiring is compromised during the transient event—avoiding a potential 8-hour outage for actuator replacement.

IS200ERIOH1A

Related Model Recommendations

IS200TBCIH1A: GE’s turbine bypass control interface module that pairs directly with the IS200TBAOH1B. The IS200TBCIH1A monitors valve position and pressure, sending digital commands to the IS200TBAOH1B to adjust actuator signals—forming a complete bypass control loop.

IS200DTAIH1A: GE’s 16-channel digital input module that complements the IS200TBAOH1B. It adds digital inputs for bypass valve limit switches (e.g., “fully open,” “fully closed”), providing redundant status checks alongside the IS200TBAOH1B’s analog feedback.

IS200IVFBG1A: GE’s voltage/frequency feedback module that works with the IS200TBAOH1B. It monitors generator voltage, which the Mark VI uses to adjust the IS200TBAOH1B’s output signals (e.g., reducing bypass flow when generator voltage stabilizes).

IS200HFPAG1A: GE’s high-frequency power supply module that powers the IS200TBAOH1B (via 24 V DC output). Its stable power ensures the IS200TBAOH1B’s analog signals remain accurate during grid voltage fluctuations (e.g., ±10% shifts).

IS200EACFG1A: GE’s system configuration module that stores the IS200TBAOH1B’s channel settings (e.g., 4-20 mA scaling, fault thresholds). It enables plug-and-play replacement, restoring configuration in 30 seconds to minimize downtime.

IS200JGNDG1A: GE’s system grounding module that enhances the IS200TBAOH1B’s signal integrity. Its low-impedance grounding reduces noise in analog output signals, preventing false valve adjustments caused by EMI from turbine generators.

GE BV-200 Bypass Valve Actuator: A hydraulic bypass valve actuator designed to pair with the IS200TBAOH1B. It accepts the module’s 4-20 mA signals and provides RS-485 feedback, ensuring seamless integration and optimal performance.

IS200DSPXH1D: GE’s digital signal processor module that optimizes commands for the IS200TBAOH1B. It runs advanced control algorithms (e.g., feedforward control for predicted load changes) to generate smooth, pre-emptive output signals—reducing valve hunting by 30%.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the IS200TBAOH1B, power off the Mark VI backplane and bypass valve control cabinet. Verify the environment meets the module’s -40 °C to +85 °C range and use ESD-safe tools (grounded tweezers, antistatic mat) to protect SMT components. Confirm the backplane slot is compatible with Mark VI analog output modules and check the 24 V DC power supply (±15% tolerance) to avoid damage. For wiring: use shielded twisted-pair cables (22 AWG for analog signals) and ground the shield at the actuator end (per GE’s EMC guidelines) to reduce noise. Label each channel (e.g., “HP Bypass Valve Output 1”) to avoid misconnection to the wrong actuator.

Commissioning and Maintenance

During commissioning, use GE’s Mark VI Toolbox software to configure the IS200TBAOH1B: set each channel to 4-20 mA or 0-10 V DC, scale signals (e.g., 4 mA = 0% open, 20 mA = 100% open), and enable RS-485 feedback. Test each channel by sending a 12 mA (50% open) command and verifying the actuator responds correctly—cross-checking with the module’s feedback data to ensure alignment within ±0.1%. For maintenance: inspect the IS200TBAOH1B’s LEDs daily—red LEDs indicate channel faults (e.g., shorted actuator wiring) that require immediate troubleshooting. Every 6 months, calibrate outputs using a NIST-traceable current meter and clean module vents with compressed air (max 40 psi) to remove dust. If the module fails, first check RS-485 and power connections before replacing it with a GE-approved IS200TBAOH1B—third-party modules may lack bypass-specific calibration, leading to valve control errors.

Service and Guarantee Commitment

The IS200TBAOH1B comes with a 2-year standard warranty from GE, covering defects in materials, workmanship, and performance under normal Mark VI operation. If the module fails within this period (e.g., output drift, communication errors), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize turbine downtime—critical for plants where bypass valve issues can delay startup by 2+ hours.

GE offers 24/7 global technical support for the IS200TBAOH1B: certified Mark VI engineers specialize in bypass control systems and assist with configuration, calibration, and troubleshooting via phone, email, or remote access. Customers gain access to GE’s Digital Industrial Library, which includes the IS200TBAOH1B’s technical manual, actuator pairing guides, and fault diagnostic flowcharts. For mission-critical applications (e.g., nuclear power plant steam turbines), GE provides extended warranty options (up to 5 years) and annual preventive maintenance—trained technicians perform on-site output accuracy testing and feedback loop validation to ensure the IS200TBAOH1B meets IEC 61508 SIL 2 safety standards.