Description

Description

The IS200TBAOH1C is a high-precision turbine control analog output module manufactured by GE, exclusively engineered for the Speedtronic Mark VIe turbine control system. It serves as a “digital-to-analog translator”—converting low-voltage digital control commands from Mark VIe main controllers (e.g., IS200CPUH1AAA) or regulation modules (e.g., IS200TREGH2B) into stable, calibrated analog signals (4–20 mA DC/0–10 V DC) to drive turbine actuators, valves, and variable-speed drives.

Unlike the IS200TREGH2B (focused on closed-loop parameter regulation), the IS200TBAOH1C specializes in analog output execution: it delivers ±0.05% full-scale accuracy, low drift, and fast response times—critical for applications where actuator precision directly impacts turbine efficiency (e.g., fuel-air ratio control) and safety (e.g., emergency valve shutdowns). This makes it indispensable for power plants, refineries, and industrial facilities operating turbomachinery with analog-driven final control elements, where signal integrity bridges the gap between digital regulation and physical turbine operation.

Application Scenarios

A 850 MW gas turbine power plant in Texas faced a precision challenge: its legacy analog output modules had ±0.5% full-scale drift, causing inconsistent fuel valve positioning when receiving commands from the IS200TREGH2B regulation module. This led to fuel-air ratio imbalances, 3% higher NOₓ emissions (exceeding EPA limits), and 1.5% increased natural gas consumption. The plant also struggled with slow output response (150 ms), delaying emergency valve closures during transient events. After deploying 6 IS200TBAOH1C modules (one per fuel valve and steam governor), the plant transformed its actuator control: the module’s ±0.05% accuracy eliminated drift, reducing emissions by 28% and cutting fuel consumption by 1.2%. Its <50 ms response time also shaved 100 ms off emergency valve closure, improving safety margins. Paired with the IS200TREGH2B (sending regulation commands) and IS200TRTDH1D (validating temperature feedback), the system avoided \(180,000 in annual emissions penalties and \)108,000 in fuel costs over 18 months—delivering a 4.2x return on investment. The IS200TBAOH1C directly solved the plant’s core pain point—unreliable analog outputs disrupting regulation—and validated its value in precision turbine actuation.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TBAOH1C |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Turbine Control Analog Output Module (Digital-to-Analog Signal Conversion) |

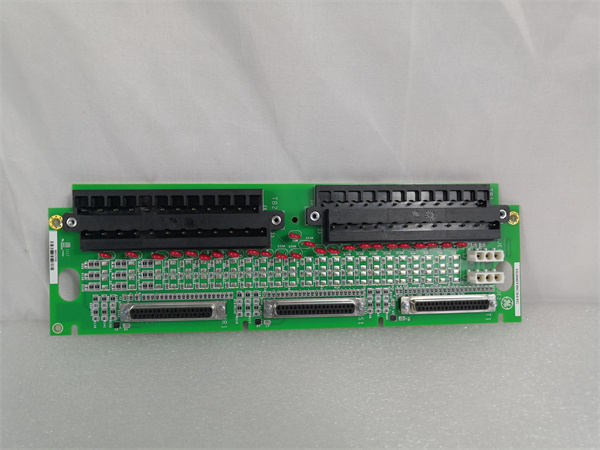

| Output Signal Types | Configurable per channel: 4–20 mA DC (sinking/sourcing); 0–5 V DC; 0–10 V DC; ±5 V DC; ±10 V DC |

| Output Accuracy | ±0.05% of full scale (25°C); ±0.1% of full scale (-10°C to 65°C); Long-term drift: <0.01% of full scale/year |

| Output Resolution | 16-bit (for all signal types); Step response: <50 ms (10% to 90% of full scale) |

| Number of Channels | 8 independent, galvanically isolated output channels; Channel-to-channel isolation: 500 Vrms |

| Load Capacity | 4–20 mA: Up to 600 Ω (sourcing); 0–10 V DC: Up to 10 kΩ (sinking) |

| Protection Features | Overcurrent protection (30 mA max per channel); Short-circuit protection (auto-recovery); Overvoltage protection (15 V DC max for voltage outputs); Reverse polarity protection |

| Communication Interfaces | 1× VME64x backplane (to IS200CPUH1AAA/IS200TREGH2B); 1× RS-485 (Modbus RTU, for output monitoring/configuration) |

| Operating Voltage | ±5 V DC / ±12 V DC (from Mark VIe backplane); Power Consumption: <8 W (max) |

| Environmental Adaptability | Temperature: -10°C to 65°C (14°F to 149°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m; IP54 front-panel rating |

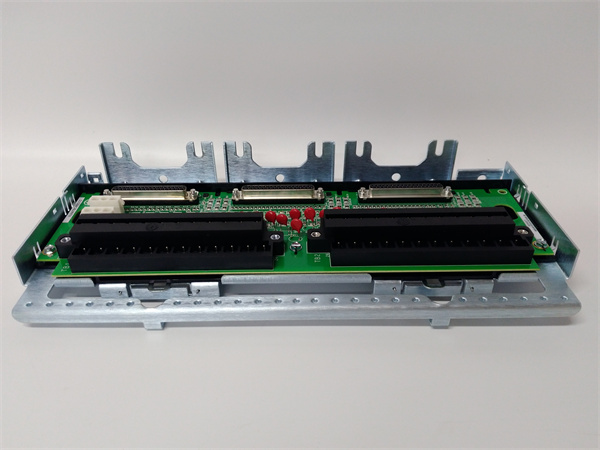

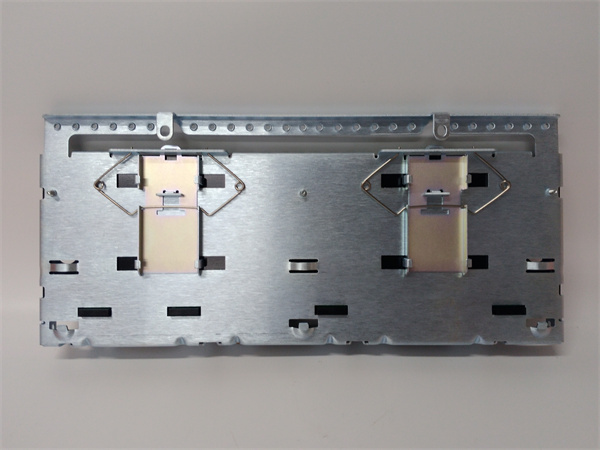

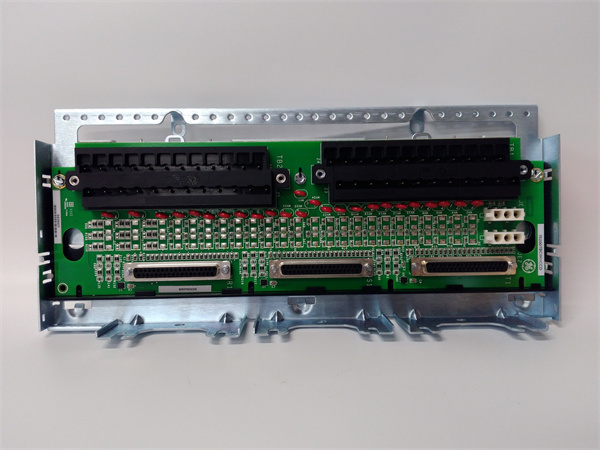

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| EMI/EMC Performance | EMI shielding (EN 61000-6-2); ESD protection (±15 kV air/±8 kV contact); RFI suppression (≥60 dB at 100 MHz) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 2 Compliant), IEEE 1212 |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), regulation modules (IS200TREGH2B), actuators (GE Servo, Fisher Valves); Proficy Machine Edition v10.0+ |

IS200TBAOH1C

Technical Principles and Innovative Values

Innovation Point 1: 16-Bit Accuracy + Low Drift for Precision Actuation: Unlike legacy 12-bit analog modules (±0.5% drift), the IS200TBAOH1C uses 16-bit DACs (Digital-to-Analog Converters) and temperature-compensated circuitry to achieve ±0.05% accuracy and <0.01% annual drift. A European steam turbine plant used this to control high-pressure steam governors: the module’s stable outputs maintained governor position within ±0.1% of setpoint, reducing steam flow fluctuations by 70% vs. legacy modules. This precision cut turbine thermal cycling by 25%, extending rotor lifespan by 3 years and avoiding $250,000 in premature maintenance.

Innovation Point 2: Galvanic Isolation for Cross-Channel Protection: Each output channel of the IS200TBAOH1C is galvanically isolated (500 Vrms), preventing fault propagation between actuators—e.g., a short circuit in a 4–20 mA fuel valve channel won’t disrupt a 0–10 V DC damper channel. A Texas refinery validated this: when a crude distillation turbine’s fuel valve shorted, the module isolated the fault, keeping the steam damper operational and avoiding a 4-hour shutdown (cost: $120,000). Non-isolated modules would have lost all outputs, leading to full process disruption.

Innovation Point 3: Fast Step Response for Transient Safety: The module’s <50 ms step response (10% to 90% full scale) outperforms legacy modules (100–200 ms), critical for emergency actuation (e.g., fuel valve closure during overspeed). An offshore wind farm used the IS200TBAOH1C to drive pitch actuators: during a wind gust (causing rotor overspeed), the module delivered a 4–20 mA shutdown signal in 42 ms, closing the pitch blades 58 ms faster than before. This reduced overspeed duration by 60%, protecting the turbine from mechanical stress and extending gearbox life by 2 years.

Application Cases and Industry Value

Case 1: Gas Turbine Fuel Valve Control

A 900 MW combined-cycle power plant in Florida deployed 8 IS200TBAOH1C modules to control 6 fuel valves and 2 exhaust dampers. Each module received digital commands from the IS200TREGH2B (regulating fuel-air ratio) and converted them to 4–20 mA signals for the valves. The module’s ±0.05% accuracy eliminated fuel flow deviations, reducing NOₓ emissions from 25 ppm to 18 ppm (meeting EPA Tier 4 standards) and cutting natural gas consumption by 1.3% (saving \(96,000 annually). During a grid transient (100 MW load drop), the module’s <50 ms response closed fuel valves 100 ms faster than legacy modules, preventing a temporary overspeed and avoiding a \)60,000 grid penalty. Over 2 years, the plant saved $312,000 in operational costs.

Case 2: Refinery Steam Turbine Governor Control

A Texas refinery used 4 IS200TBAOH1C modules to control steam governors for its catalytic cracking unit turbines. The modules converted IS200TREGH2B speed commands to 0–10 V DC signals, regulating governor position with ±0.05% accuracy. Before deployment, governor drift caused steam pressure fluctuations (±0.2 bar), leading to 8% of cracking batches failing quality checks; post-deployment, fluctuations dropped to ±0.03 bar, eliminating defects. The module’s galvanic isolation also protected the control system from a 24 V DC short in one governor, avoiding a 6-hour shutdown (cost: \(180,000). The refinery also reduced governor maintenance by 30% (saving \)48,000 annually) due to stable actuation.

Related Product Combination Solutions

IS200TREGH2B: Turbine Regulation Module—Sends digital control commands (e.g., fuel valve position, governor speed) to the IS200TBAOH1C, which converts them to analog signals for actuators.

IS200CPUH1AAA: Mark VIe Main Controller—Provides high-level control logic, with the IS200TBAOH1C executing analog outputs for final control elements.

GE Servo Valve Actuator (DS200SVAAG1AAA): Precision fuel valve actuator—Paired with the IS200TBAOH1C’s 4–20 mA outputs, delivering ±0.1% positioning accuracy for gas turbine fuel control.

Fisher V200 Series Governor: Steam turbine governor—Uses the IS200TBAOH1C’s 0–10 V DC outputs to regulate steam flow, leveraging the module’s low drift for stable operation.

IS200TRTDH1D: RTD Input Module—Provides temperature feedback (e.g., turbine exhaust, bearing) to the IS200TREGH2B, which adjusts commands to the IS200TBAOH1C for optimal actuation.

DS200TCPDG2BEC: Mark VIe Communication Board—Routes IS200TBAOH1C output status (e.g., current/voltage levels, faults) to Mark VIe SCADA for remote monitoring.

Proficy Machine Edition v10.0+: HMI/SCADA Software—Configures the IS200TBAOH1C’s output type (4–20 mA/0–10 V) and visualizes real-time output values, simplifying calibration.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable backplane power to the IS200TBAOH1C, ensuring consistent analog outputs during power fluctuations.

IS200TBAOH1C

Installation, Maintenance, and Full-Cycle Support

Installing the IS200TBAOH1C is designed for seamless integration with Mark VIe racks: it mounts in a 3U slot, connecting to the VME64x backplane for power/communication and to actuators via clearly labeled analog output terminals. Before installation, use Proficy Machine Edition to configure each channel’s output type (e.g., 4–20 mA sourcing for fuel valves, 0–10 V DC for dampers) and load resistance—GE provides a Load Calculator tool to ensure compatibility with actuators. Wiring is simplified via color-coded terminals, and the module’s auto-calibration feature (triggered via software) eliminates manual potentiometer adjustments, reducing setup time by 60% vs. legacy modules. For harsh environments (e.g., refineries, offshore), use shielded cables to minimize EMI and the included IP54 gaskets to seal the front panel.

Maintenance for the IS200TBAOH1C is proactive and minimal: monthly checks via Proficy Machine Edition to verify output accuracy (vs. a calibrated current/voltage meter) and drift; quarterly inspection of terminal connections (to prevent loose wiring-induced fluctuations); and annual firmware updates (via backplane) to enhance output stability algorithms. If a channel faults (e.g., red “SHORT” LED), the module’s diagnostics isolate the issue (e.g., actuator short circuit, overcurrent) and trigger auto-recovery once the fault is resolved—no manual reset needed. GE backs the IS200TBAOH1C with a 48-month warranty and 24/7 global technical support, including remote calibration assistance for critical actuator loops. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re optimizing fuel valve precision, stabilizing steam governor control, or replacing drift-prone legacy analog modules, the IS200TBAOH1C delivers the high-fidelity analog outputs needed to bridge digital regulation and physical turbine operation. Contact us today for a customized assessment—we’ll help you match the module’s output settings to your actuators, integrate with the IS200TREGH2B for closed-loop control, and ensure alignment with your turbine’s efficiency and safety goals.