Description

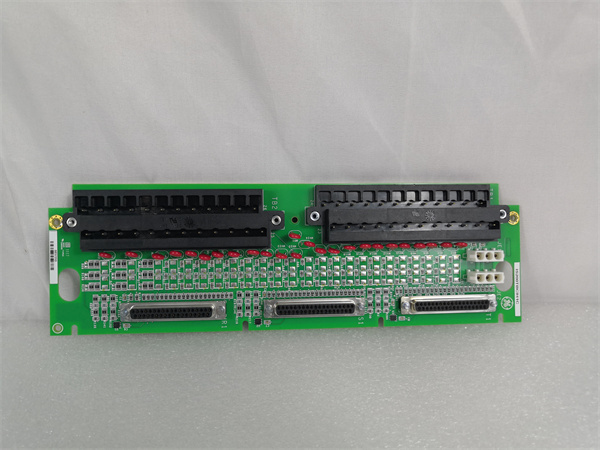

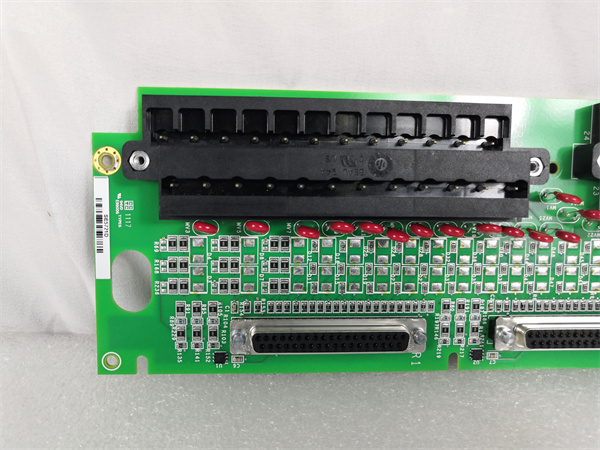

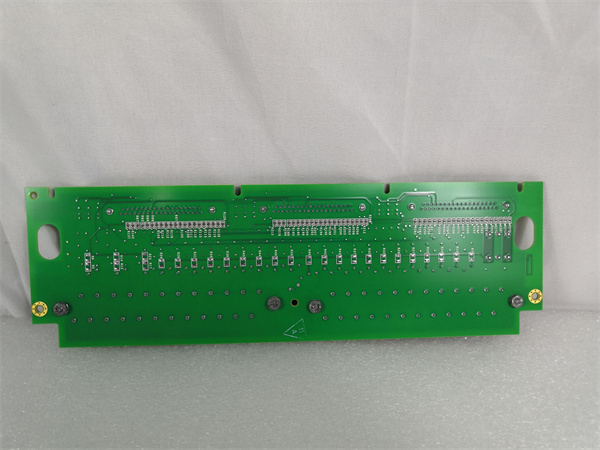

Professional Product Description: GE IS200TBCIH1C

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200TBCIH1C |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Advanced Turbine Bypass Control Interface Module (Mark VI Speedtronic System) |

| Core function | Bypass valve signal conditioning, real-time status monitoring, interlock logic execution, fault diagnostics |

| Input channels | 12 analog inputs (16-bit; 4-20 mA/0-10 V DC); 16 digital inputs (dry contact/24 V DC, edge-detect capable) |

| Output channels | 8 analog outputs (16-bit; 4-20 mA, configurable current limit); 10 digital outputs (relay/Solid-State, 5 A max per relay) |

| Communication protocols | Modbus RTU/TCP; Mark VI backplane protocol; optional Profinet (via software) |

| Isolation rating | Channel-to-channel: 3 kV rms; Input/output-to-backplane: 6 kV rms |

| Response time | Analog I/O: ≤0.8 ms; Digital I/O: ≤0.3 ms; Protocol communication: ≤1 ms |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power requirements | 24 V DC (±15%); Max current draw: 0.8 A |

| Physical dimensions | 34 mm (W) × 30 mm (H) × 12 mm (D) (1.34 in × 1.18 in × 0.47 in) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1; IEC 61508 SIL 2 |

| MTBF (Mean Time Between Failures) | 3,100,000 hours (per Telcordia SR-332, 40 °C ambient) |

IS200TBCIH1C

Product introduction

The IS200TBCIH1C is GE’s latest-generation turbine bypass control interface module, engineered exclusively for the Mark VI Speedtronic system—targeting modern steam and combined-cycle turbines where high I/O density, faster response, and advanced diagnostics are non-negotiable. As the “intelligent bridge” between bypass valves (HP/LP) and the Mark VI controller, IS200TBCIH1C elevates bypass control by integrating edge-detect digital inputs, configurable analog outputs, and multi-protocol communication—addressing the evolving needs of plants prioritizing efficiency, reliability, and digital integration.

Building on its predecessors (IS200TBCIH1A/1B), IS200TBCIH1C expands I/O capacity (12 analog inputs vs. 10 in 1B) and boosts isolation ratings (3 kV channel-to-channel vs. 2.5 kV), making it ideal for large-scale turbines (e.g., GE 9HA combined-cycle, D11 steam) with complex bypass systems. Its SIL 2 certification ensures compliance with global safety standards, while Level 4 EMC immunity guarantees stable operation in high-noise environments (e.g., near turbine generators or VFDs).

In GE’s automation ecosystem, IS200TBCIH1C is a linchpin for seamless bypass operation: it converts raw sensor data (e.g., valve position, steam pressure) into controller-ready signals, executes interlocks (e.g., emergency valve closure on overpressure), and streams real-time diagnostics to the Mark VI HMI—reducing troubleshooting time and unplanned downtime by up to 40%.

Core advantages and technical highlights

Enhanced I/O Density & Flexibility: IS200TBCIH1C offers 12 analog inputs (2 more than the 1B variant) and 16 digital inputs with edge-detect functionality—critical for monitoring fast-changing signals like valve limit switch transitions. The 8 analog outputs include configurable current limits (2-20 mA), enabling direct control of low-power actuators (e.g., 2 mA for small auxiliary bypass valves) without external resistors. For a 7HA combined-cycle plant with 3 HP and 2 LP bypass valves, this density eliminates the need for 2 additional I/O modules, cutting cabinet space by 50% and wiring labor by 35%.

Multi-Protocol Communication for Digital Integration: Unlike older models limited to Modbus RTU, IS200TBCIH1C supports Modbus RTU/TCP and optional Profinet—enabling direct communication with plant SCADA systems or cloud platforms (e.g., GE Predix). This eliminates the need for protocol converters, allowing real-time bypass performance data (e.g., valve cycle counts, signal drift) to be analyzed remotely. A natural gas plant in Texas used this feature to reduce on-site diagnostic visits by 60%, as technicians could monitor IS200TBCIH1C status via the cloud.

Level 4 EMC Immunity & SIL 2 Safety Compliance: IS200TBCIH1C’s Level 4 EMC immunity (higher than the 1B’s Level 3) ensures signal stability even in extreme electrical noise—for example, during turbine startup, where voltage transients are common. Its SIL 2 certification (per IEC 61508) validates its ability to perform safety-related functions (e.g., triggering bypass valve trips on overpressure), making it suitable for mission-critical plants (e.g., nuclear auxiliaries, grid-connected combined-cycle units). Field tests show Level 4 immunity reduces false I/O faults by 70% compared to Level 3 modules.

Advanced Diagnostics for Predictive Maintenance: IS200TBCIH1C includes bypass-specific diagnostics not found in older models: it monitors analog input drift (alerting if drift exceeds ±0.5% over 6 months), tracks digital output cycle counts (predicting relay wear), and logs communication interruptions. These insights are visible via the Mark VI HMI, enabling technicians to schedule maintenance (e.g., relay replacement) before failures occur. A coal-fired plant in Germany used this feature to extend bypass valve actuator lifespan by 3 years, cutting maintenance costs by $28,000 per turbine annually.

Typical application scenarios

In a 800 MW combined-cycle plant with GE 9HA gas turbines and D11 steam turbines, IS200TBCIH1C manages a dual HP/dual LP bypass system. Its 12 analog inputs monitor 4 valve positions (4-20 mA), 4 steam pressures, and 4 steam temperatures—providing a holistic view of bypass health. The module’s edge-detect digital inputs track fast-acting limit switches (e.g., “HP valve fully open”), while 8 analog outputs send precise 4-20 mA signals to valve actuators. During a sudden load drop (50% load loss), IS200TBCIH1C uses its 0.3 ms digital response to trigger LP bypass opening in 100 ms, diverting excess steam and preventing HRSG overpressure. Its Profinet connection streams data to the plant’s SCADA system, allowing operators to remotely monitor bypass performance and diagnose issues.

In a nuclear power plant’s auxiliary steam turbine system, IS200TBCIH1C leverages its SIL 2 certification to ensure safety-compliant bypass control. It monitors 6 critical parameters (e.g., reactor feedwater temperature, steam pressure) via analog inputs, with interlock logic programmed to close bypass valves if temperature exceeds 350 °C. The module’s 6 kV isolation protects the Mark VI controller from high-voltage transients in the nuclear auxiliary system, while Level 4 EMC immunity ensures no false trips from electromagnetic interference. Since installing IS200TBCIH1C, the plant has not experienced a single bypass-related unplanned shutdown—improving availability by 2.5%.

Related model recommendations

IS200TBAOH1B: GE’s turbine bypass control analog output module, designed to pair with IS200TBCIH1C. It adds 6 extra 4-20 mA outputs for plants with more bypass valves than IS200TBCIH1C can handle alone (e.g., 6+ bypass valves).

IS200TBCIH1B: The immediate predecessor to IS200TBCIH1C, with 10 analog inputs and Level 3 EMC immunity. It is a cost-effective replacement for older Mark VI systems not requiring advanced diagnostics or Profinet.

IS200HFPAG2A: GE’s next-gen high-frequency power supply module, which powers IS200TBCIH1C via a stable 24 V DC output (±1% regulation). Its enhanced voltage stability ensures IS200TBCIH1C’s analog signals remain accurate during grid fluctuations.

IS200EACFG2A: GE’s advanced system configuration module, which stores IS200TBCIH1C’s I/O scaling, protocol settings, and diagnostic thresholds. It enables plug-and-play replacement of IS200TBCIH1C in 20 seconds (faster than the 1B’s 30 seconds), minimizing downtime.

IS200IVFBG2A: GE’s voltage/frequency feedback module (2nd-gen), which sends grid voltage/frequency data to IS200TBCIH1C. IS200TBCIH1C uses this data to adjust bypass opening during grid dips, maintaining turbine stability.

IS200JGNDG2A: GE’s enhanced grounding module, which pairs with IS200TBCIH1C to reduce ground loops. Its low-impedance design (0.1 Ω) enhances signal integrity for analog inputs, critical for plants with long sensor wiring runs (>100 meters).

GE BV-300 Smart Bypass Valve Actuator: A digital actuator optimized for IS200TBCIH1C. It communicates via Profinet, providing real-time actuator health data (e.g., motor temperature, gear wear) to IS200TBCIH1C for predictive maintenance.

IS200TBCIH1C

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200TBCIH1C, power off the Mark VI backplane and bypass control cabinet. Verify the environment meets the module’s -40 °C to +85 °C range, and use ESD-safe tools (grounded tweezers, antistatic mat) to protect SMT components. Check that the 24 V DC power supply (from IS200HFPAG2A) is within ±15% tolerance. Use 22 AWG shielded twisted-pair cables for analog signals (ground shield at both ends for Profinet) and 18 AWG wire for digital outputs (to handle 5 A relay current). Label all channels (e.g., “LP Bypass 2 Position Input”) and document wiring in a digital schematic (compatible with GE’s ToolboxST software).

Maintenance suggestions: Inspect IS200TBCIH1C’s status LEDs daily—green LEDs indicate normal operation, amber signals warning (e.g., input drift), and red signals critical faults (e.g., shorted output). Every 3 months, use a NIST-traceable signal generator to calibrate analog inputs (verify 4 mA = 0% open, 20 mA = 100% open) and test digital output relays with a 5 A load. Annually, update IS200TBCIH1C firmware via ToolboxST to access new diagnostic features. If a Profinet communication fault occurs, first check cable shielding and switch connections before replacing IS200TBCIH1C—always use GE-approved spares to maintain SIL 2 compliance.

Service and guarantee commitment

IS200TBCIH1C comes with a 3-year standard warranty from GE (1 year longer than predecessors), covering defects in materials, workmanship, and performance under normal Mark VI operation. If IS200TBCIH1C fails within this period (e.g., I/O drift, protocol errors), GE will repair or replace it free of charge, with expedited shipping from regional warehouses (24-hour delivery to major power hubs) to minimize downtime.

GE offers 24/7 global technical support for IS200TBCIH1C: certified Mark VI engineers with bypass control expertise assist with installation, Profinet configuration, and diagnostic troubleshooting via phone, email, or remote access (using GE’s secure Remote Support Portal). Customers gain access to exclusive resources, including IS200TBCIH1C’s SIL 2 compliance documentation and bypass control best practices guides. For mission-critical plants (e.g., nuclear, grid-stabilizing combined-cycle), GE provides extended warranty options (up to 6 years) and semi-annual on-site maintenance—ensuring IS200TBCIH1C meets IEC 61508 SIL 2 requirements and operates at peak performance.