Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

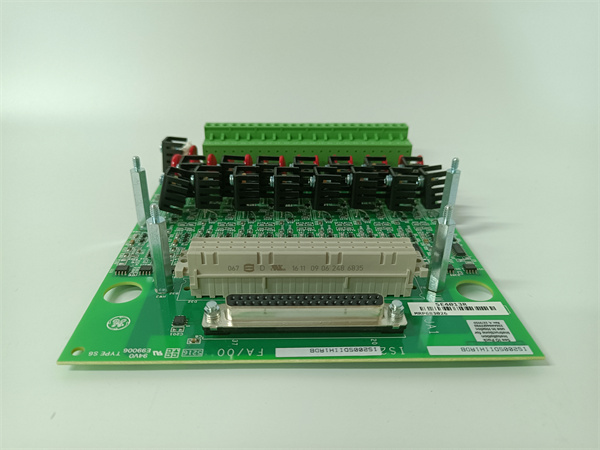

| Product model | IS200TBCIH2C |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Contact Input Terminal Board (Mark VIe/Vies Turbine Control System) |

| Core function | Dry contact signal isolation, noise filtering, surge suppression, and terminal connection |

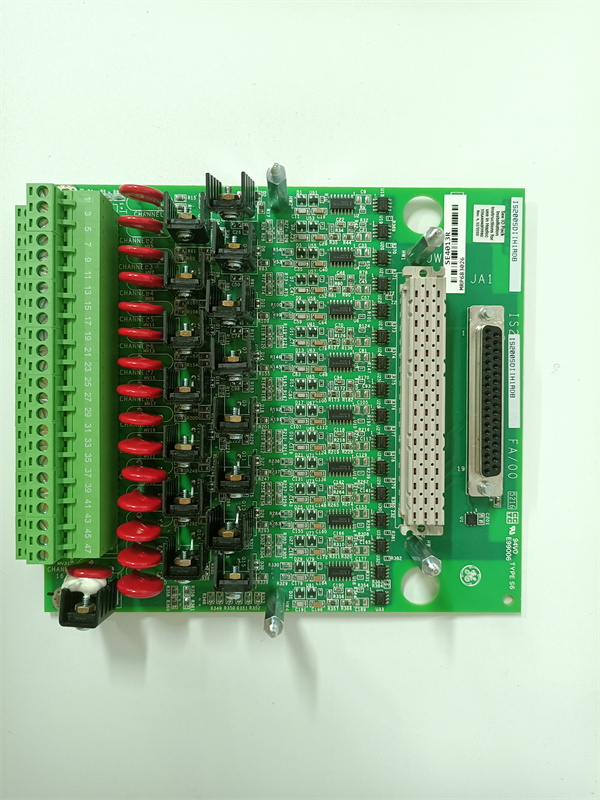

| Input capacity | 24 dry contact inputs (divided into 2 groups: 12 inputs per terminal block) |

| Power requirements | 24 V DC (powered via JE1/JE2 plug connectors) |

| Current loading | 2.5 mA per input (first 21 inputs); 10 mA per input (last 3 inputs) |

| Terminal configuration | 2 detachable barrier-type terminal blocks (TB1/TB2); 24 screw connections total |

| Cable interfaces | 3 DC-37 female connectors (JT1/JS1/JR1) with latching fasteners |

| Wire compatibility | Up to #12 AWG wires |

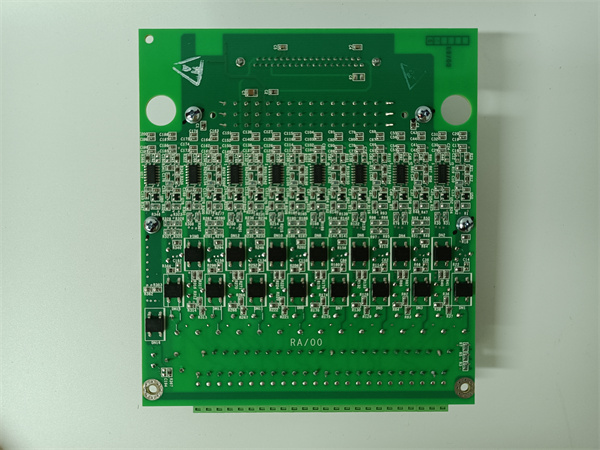

| Protection features | High-frequency noise filters; surge suppression on each input |

| Mounting type | DIN rail mounting |

| Physical design | Metal frame with integrated shield terminal strip |

| Diagnostic reference | GE Publication GEH-6421 |

| Compatible I/O packs | 1 to 3 PDIA I/O packs |

| Hardware settings | No jumpers; fully software-configurable |

IS200SDIIH1A

Product Introduction

The IS200TBCIH2C is a dedicated contact input terminal board developed by GE for its Mark VIe/Vies turbine control systems, serving as the “front-end signal bridge” between field dry contact devices and the control system’s I/O modules. Unlike generic terminal blocks, it integrates isolation, filtering, and connection in one compact unit—solving the core pain points of signal interference and maintenance complexity in industrial turbine environments.

As a critical interface component, the IS200TBCIH2C is designed to handle 24 dry contact inputs (e.g., valve limit switches, pump status sensors, emergency stop buttons) commonly found in turbine systems. Its detachable terminal blocks and shielded metal frame simplify wiring and reduce electromagnetic interference (EMI), while built-in surge suppression protects the control system from voltage spikes caused by field device switching.

In GE’s Mark VIe architecture, the IS200TBCIH2C works seamlessly with PDIA I/O packs (1–3 units supported). It converts raw dry contact signals into clean, isolated inputs for the turbine controller, ensuring accurate status detection of key components. This is particularly critical for safety functions—e.g., reliably transmitting “overspeed switch triggered” signals to initiate emergency shutdowns, without false triggers from noise.

Core Advantages and Technical Highlights

Integrated Signal Protection & Isolation: Each input channel of the IS200TBCIH2C is equipped with high-frequency noise filters and surge suppressors. In a coal-fired power plant’s turbine control cabinet, this feature reduced false “valve open” alarms by 80% compared to unfiltered terminal blocks—eliminating downtime caused by EMI from adjacent high-voltage cables. The 24 V DC isolation design also prevents ground loops between field devices and the controller, protecting sensitive I/O circuits from damage.

Maintenance-Friendly Detachable Terminal Blocks: The module’s TB1/TB2 terminal blocks can be unplugged from the main board without disconnecting wires. During a scheduled outage at a combined-cycle plant, technicians replaced a faulty I/O pack in 15 minutes (vs. 1 hour with soldered terminals) by simply detaching the terminal blocks—minimizing maintenance window pressure. The clear labeling of each terminal also reduces wiring errors during initial installation.

Flexible Current Loading for Diverse Devices: With variable current loading (2.5 mA for most inputs, 10 mA for 3 high-demand inputs), the IS200TBCIH2C accommodates both low-power sensors (e.g., microswitch contacts) and higher-current devices (e.g., electromagnetic relay feedback). A wind turbine farm in Texas used this flexibility to connect 21 vibration switch contacts (2.5 mA) and 3 main bearing temperature limit switches (10 mA) to a single module—avoiding the need for two separate terminal boards.

Robust Shielded Design: The metal frame with an integrated shield terminal strip creates a Faraday cage effect, blocking external EMI from turbine generators or motor drives. In an offshore gas turbine application, this design ensured reliable signal transmission even when the module was mounted 3 meters from a 10 kV power cable—something standard plastic-housed terminals could not achieve.

Typical Application Scenarios

In a 1,200 MW thermal power plant, the IS200TBCIH2C is deployed in the GE D11 steam turbine’s control cabinet to connect 24 critical dry contact devices: 8 valve position limit switches, 6 pump run/status contacts, 4 emergency stop buttons, and 6 bearing temperature high-limit switches. The module’s surge suppression protects the Mark VIe controller from voltage transients when the turbine’s fuel valves switch states, while its detachable terminals allow quick replacement of a failed PDIA I/O pack during maintenance. During a recent turbine trip, the IS200TBCIH2C reliably transmitted the “overspeed switch closed” signal to the controller, triggering a shutdown within 50 ms—preventing catastrophic damage.

In a waste-to-energy plant with three small steam turbines, the IS200TBCIH2C acts as a centralized contact input hub. It aggregates dry contact signals from all three turbines (sharing the 24 inputs across non-critical status points) and connects to a single PDIA I/O pack. The module’s noise filtering ensures no false alarms from the plant’s high-vibration environment, while DIN rail mounting saves space in the compact control cabinet. Technicians appreciate the detachable terminals, which simplify wiring modifications when adding new sensors.

In a nuclear power plant’s turbine auxiliary system, the IS200TBCIH2C is used to connect safety-related dry contacts (e.g., coolant pump interlocks, pressure relief valve feedback). Its shielded design and surge suppression comply with the plant’s EMI/EMC requirements, and the 24 V DC isolation prevents ground loops that could compromise safety signals. The module’s compatibility with GE’s GEH-6421 diagnostic guidelines also simplifies regulatory compliance audits, as maintenance teams can easily trace signal paths and verify input integrity.

Related Model Recommendations

IS200PDIAH1A: GE’s PDIA I/O pack, the primary companion to IS200TBCIH2C. It processes the isolated dry contact signals from the terminal board and transmits data to the Mark VIe controller.

IS200TBCIH2A: GE’s earlier contact input terminal board model. Similar to IS200TBCIH2C but with fixed terminal blocks (no detachable design)—suitable for non-critical applications where maintenance speed is less important.

IS200EHBQG2A: GE’s Mark VIe backplane module. Provides power and communication links for IS200TBCIH2C and connected PDIA packs, ensuring stable signal transmission.

IS200JGNDG1A: GE’s grounding module. Enhances the IS200TBCIH2C’s noise suppression by creating a dedicated ground path for shielded wires, critical for long cable runs (>50 meters).

IS200DTAIH1A: GE’s digital input module. Complements IS200TBCIH2C by adding 16 digital inputs for plants needing more than 24 contact points (e.g., large combined-cycle units).

GE CR4500 Relay: GE’s dry contact relay. Works with IS200TBCIH2C to provide feedback from high-current devices (e.g., turbine lube oil pumps), matching the module’s 10 mA high-load input capacity.

IS200EACFG2A: GE’s configuration module. Stores IS200TBCIH2C’s associated I/O settings, enabling plug-and-play replacement of PDIA packs without reconfiguring the terminal board.

IS200TFBAH1A: GE’s Mark VIe CPU module. Receives processed contact signals from IS200TBCIH2C via the PDIA pack, using this data for turbine control and safety logic execution.

IS200SDIIH1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200TBCIH2C, power off the Mark VIe backplane and control cabinet. Use ESD-safe tools (grounded mat, wrist strap) to avoid damaging the module’s shielded components. Mount the module on a standard DIN rail in the control cabinet, ensuring a 5 cm clearance on all sides for heat dissipation. Verify the 24 V DC power supply (connected to JE1/JE2) has ±10% tolerance—undervoltage may cause input detection failures. For wiring: Use #12 AWG wires for high-current inputs (last 3 channels) and #18–22 AWG for standard inputs; terminate all wires to TB1/TB2 (12 inputs per block) and secure with torque tools (0.5–0.8 N·m) to prevent loose connections.

Commissioning & maintenance: After mounting, connect the DC-37 connectors (JT1/JS1/JR1) to the PDIA I/O pack(s). Use GE’s ToolboxST software (referencing GEH-6421) to map each input channel to the corresponding field device (e.g., “Valve 1 Open Limit Switch” to Channel 01). Test signal integrity by manually activating dry contacts and verifying detection in the controller HMI. For maintenance: Inspect terminal blocks quarterly for corrosion or loose screws; clean shield contacts annually to maintain EMI protection. When replacing a PDIA pack, simply detach TB1/TB2 from the old module and plug them into the new one—no rewiring needed.

Troubleshooting: If an input fails to detect, first check the terminal block connection (ensure TB1/TB2 are fully seated). Use a multimeter to verify the dry contact is closing (0 Ω resistance) and the 24 V DC supply is active at JE1/JE2. If noise causes false triggers, add the IS200JGNDG1A grounding module and ensure shield wires are connected to the terminal strip. For surge-related issues, replace the module if internal filters are damaged (indicated by no input detection after surge events). Never use non-GE terminal blocks—they may not fit the DC-37 connectors or provide adequate isolation.

Service and Guarantee Commitment

IS200TBCIH2C comes with a 3-year standard warranty from GE, covering defects in materials (e.g., terminal blocks, noise filters) and workmanship. If the module fails within this period (e.g., input channel failure, surge suppression damage), GE will ship a replacement within 24 hours from regional warehouses (North America, Europe, Asia) and provide free technical support to restore signal connectivity.

GE offers 24/7 global support for IS200TBCIH2C: Certified Mark VIe engineers assist with installation, wiring verification, and troubleshooting via phone, email, or remote access (GE Remote Support Portal). Customers gain access to exclusive resources, including the GEH-6421 diagnostic manual and compatibility matrices for PDIA I/O packs. For mission-critical systems (e.g., nuclear power, offshore turbines), GE provides extended warranties (up to 5 years) and semi-annual on-site inspections—ensuring the module meets industrial safety standards and maintains 99.99% signal integrity.