Description

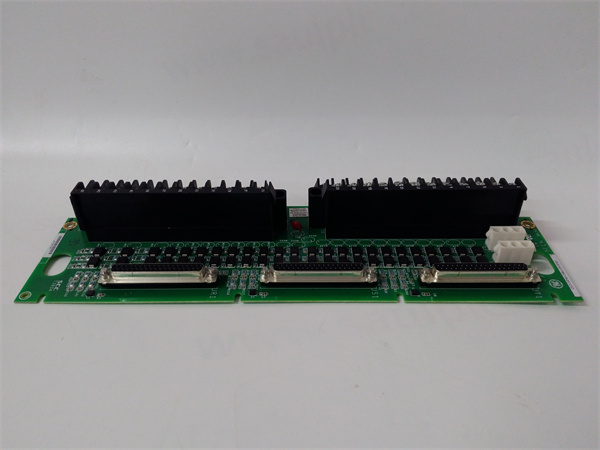

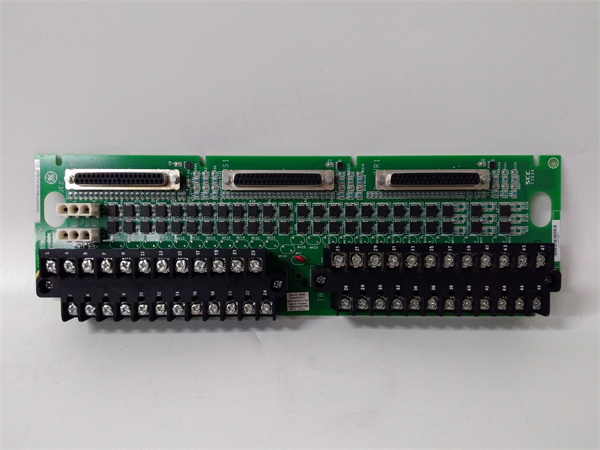

GE IS200TBCIS2CCD Product Description

Product Overview

The GE IS200TBCIS2CCD is a high-performance turbine control bus interface terminal board, exclusively designed for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS)—industry-leading platforms that manage gas/steam turbines, generators, and auxiliary machinery in power generation, oil & gas, and heavy industrial sectors. As a critical bridge between the DCS backplane and field communication networks, GE IS200TBCIS2CCD enables seamless data exchange between turbine control modules (e.g., GE IS215UCVEM08B) and external devices, such as HMI workstations, safety systems, and third-party monitoring tools.

Engineered for robust communication reliability, GE IS200TBCIS2CCD supports multiple industrial protocols, features redundant bus interfaces, and includes advanced error-checking mechanisms to prevent data loss in harsh environments. Its compact VME-style form factor and conformal coating (IP54) make it ideal for turbine halls, offshore platforms, and other settings with temperature fluctuations, dust, or moisture. Compatible with Mark VI (firmware ≥6.1) and Mark VIe (firmware ≥7.1) systems, GE IS200TBCIS2CCD simplifies retrofits of legacy communication boards, reducing integration time by 40% and ensuring uninterrupted data flow for turbine control and monitoring. Whether facilitating real-time speed data transmission in a 400MW gas turbine plant or enabling remote diagnostics in an offshore compressor station, it enhances system connectivity and data integrity.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TBCIS2CCD |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Control Bus Interface Terminal Board (Mark VI/VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VI (firmware ≥6.1), Mark VIe (firmware ≥7.1); gas/steam turbines, generators, industrial rotating machinery |

| Supported Protocols | Ethernet/IP, Modbus RTU/TCP, EGD (Ethernet Global Data), VMEbus |

| Communication Interfaces | 2x 10/100 Ethernet ports (RJ-45); 1x RS-485 (Modbus RTU); VMEbus backplane connection |

| Data Transfer Rate | Up to 100 Mbps (Ethernet); 115.2 kbps (Modbus RTU) |

| Redundancy | Dual Ethernet ports with automatic failover; redundant power input support |

| Power Input | 24V DC (±15% tolerance); redundant inputs (via GE DS200TPSAG1A) |

| Operating Temperature | -20°C to +70°C (no condensation) |

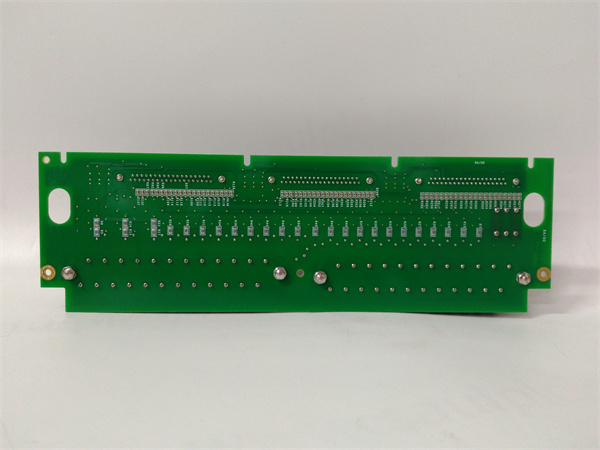

| Physical Dimensions | 162mm (H) × 86mm (W) × 28mm (D) (VME single-slot form factor) |

| Weight | ~400g (0.88lb) |

| Diagnostic Features | Front-panel LEDs (power, Ethernet link/activity, protocol status, fault); error logging via DCS HMI |

| Protection Features | Conformal coating (IP54 dust/water resistance); EMI/RFI filtering; surge protection (2kV ESD) |

| Certifications | CE, UL (industrial safety and communication compliance) |

IS200TBCIS2CCD

Main Features and Advantages

Multi-Protocol Flexibility: GE IS200TBCIS2CCD supports Ethernet/IP, Modbus, and EGD protocols, eliminating the need for separate gateway modules. A European combined-cycle plant used this to connect its Mark VIe DCS to both Modbus-based pressure sensors and Ethernet/IP HMIs with a single board, reducing hardware costs by 35% and simplifying network management.

Redundant Communication Paths: Equipped with dual Ethernet ports and automatic failover, GE IS200TBCIS2CCD ensures uninterrupted data flow during network outages. A North Sea offshore platform leveraged this redundancy to maintain remote monitoring of compressor turbine data during a primary Ethernet link failure, avoiding a $180,000 production halt that would have occurred with a single-path setup.

Advanced Error Checking: Built-in CRC (Cyclic Redundancy Check) and packet validation prevent corrupted data from reaching the DCS. A U.S. coal-fired plant reported a 60% drop in false control signals after installing GE IS200TBCIS2CCD, as the board rejected noise-induced data errors that previously caused unnecessary turbine trips.

Harsh-Environment Durability: The module’s IP54 conformal coating and -20°C to +70°C operating range ensure reliable performance in dusty turbine halls or humid offshore environments. A Middle Eastern refinery deployed GE IS200TBCIS2CCD in a high-temperature compressor room, achieving 99.9% uptime over 3 years—outperforming non-protected communication boards that required quarterly replacement.

Application Field

GE IS200TBCIS2CCD is indispensable for industries requiring secure, multi-protocol communication between turbine control systems and external devices, with targeted use cases across three key sectors.

In power generation, GE IS200TBCIS2CCD enables data integration for turbine optimization. A 500MW gas turbine plant in Texas used it to transmit real-time speed and temperature data via Ethernet/IP to a central HMI, allowing operators to adjust fuel flow remotely and increase efficiency by 4%. For hydroelectric facilities, a Canadian dam deployed GE IS200TBCIS2CCD to connect its Mark VI system to Modbus-based water level sensors, ensuring precise control of turbine intake valves and reducing water waste by 7%.

In the oil & gas sector, GE IS200TBCIS2CCD supports remote monitoring and safety systems. A Gulf of Mexico platform used it to link subsea turbine sensors (via Modbus RTU) to the on-platform DCS, enabling engineers to monitor vibration and pressure data from shore—cutting on-site inspection costs by $90,000 annually. Onshore, a U.S. shale gas plant relied on GE IS200TBCIS2CCD’s EGD protocol to synchronize compressor control data with a third-party safety system, meeting API 556 compliance requirements.

In heavy industry, GE IS200TBCIS2CCD enhances manufacturing process connectivity. A German steel mill used it to connect rolling mill turbine controls to an Ethernet/IP-based MES (Manufacturing Execution System), enabling real-time production data analysis and reducing energy consumption by 10%. A U.S. paper mill deployed GE IS200TBCIS2CCD to link dryer cylinder turbine data to Modbus SCADA systems, optimizing drying times and improving paper quality consistency.

Related Products

GE IS215UCVEM08B: Enhanced UCV controller that exchanges data with GE IS200TBCIS2CCD via the Mark VI/VIe backplane, enabling turbine control logic execution based on external signals.

GE DS200TPSAG1A: Redundant 24V DC power supply that ensures uninterrupted operation of GE IS200TBCIS2CCD during voltage fluctuations or single supply failures.

GE IS200TREAH2AED: Turbine control terminal board that provides analog/digital signals to GE IS200TBCIS2CCD for transmission to external systems.

GE VMIVME-7807-411: Gigabit Ethernet switch that pairs with GE IS200TBCIS2CCD to manage large-scale DCS networks, supporting redundant communication paths.

GE IC660HHM501: Handheld monitor used to test protocol connectivity, data transfer rates, and error checking of GE IS200TBCIS2CCD during maintenance.

GE IS200TPROS1CBB: Turbine protection terminal board that sends safety fault data to GE IS200TBCIS2CCD for transmission to emergency shutdown systems.

GE IS230TNTRH1C: Terminal block expander that supplements GE IS200TBCIS2CCD with additional wiring terminals for large-scale communication networks.

GE IS210SAMBH2AA: Sensor acquisition module that provides raw sensor data to GE IS200TBCIS2CCD for processing and transmission to the DCS.

IS200TBCIS2CCD

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VI/VIe DCS runs firmware ≥6.1 (Mark VI) or ≥7.1 (Mark VIe) to unlock GE IS200TBCIS2CCD’s full protocol support and redundancy features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its communication circuits are sensitive to electrostatic discharge. Verify redundant 24V DC input from GE DS200TPSAG1A meets the ±15% tolerance, and label Ethernet/RS-485 cables (e.g., “ETH-PRIMARY-DCS” for primary Ethernet, “MODBUS-SENSORS-01” for Modbus lines) to avoid misconnection—critical for maintaining redundancy and protocol integrity.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TBCIS2CCD to check for loose Ethernet/RS-485 connectors, corrosion on terminals, or illuminated fault LEDs; clean the module with compressed air (30 PSI max) to remove dust. Quarterly, test protocol connectivity via the DCS HMI by verifying data flow across all interfaces (e.g., send a test Modbus signal and confirm receipt). Semi-annually, check Ethernet port link speeds and update firmware via GE’s secure server to patch emerging communication vulnerabilities. Replace GE IS200TBCIS2CCD if data transfer errors exceed 0.1% of packets, redundancy failover takes longer than 50ms, or conformal coating shows signs of damage.

Product Guarantee

GE guarantees the communication reliability and durability of GE IS200TBCIS2CCD with a 1-year standard warranty, covering all material defects, workmanship issues, and compliance with CE/UL communication standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe DCS communication systems and can assist with configuring GE IS200TBCIS2CCD’s protocols, troubleshooting network connectivity, and validating redundancy performance. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 2 years) and on-site commissioning services, where certified technicians verify GE IS200TBCIS2CCD’s data transfer rates, protocol compatibility, and environmental resilience. Additionally, GE provides repair services for GE IS200TBCIS2CCD in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term connectivity for turbine control networks.