Description

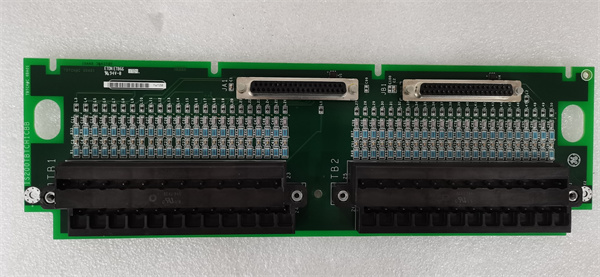

IS200TBTCH1B Product Description

Description:

The IS200TBTCH1B is a high-density terminal board developed by GE, exclusively designed for the Speedtronic™ Mark VIe turbine control system—widely used in gas, steam, and combined-cycle turbine operations. It acts as a “wiring hub” and signal termination point, organizing connections between field devices (e.g., sensors, actuators, switches) and Mark VIe I/O modules. Engineered for industrial durability and signal integrity, it simplifies wiring management, reduces interference, and speeds up troubleshooting—making it a critical component for plants aiming to enhance control system reliability and maintenance efficiency.

Application Scenarios:

A 480MW gas turbine power plant in Central Europe faced recurring issues with its turbine control wiring: unlabeled, tangled connections led to 4–5 hours of downtime per month when troubleshooting sensor signal faults. Additionally, loose terminal connections caused intermittent vibration sensor readings, leading to 2 false turbine trips in 3 months (each costing $70,000). After installing the IS200TBTCH1B to terminate wiring for 12 key I/O modules, the plant saw immediate improvements. The board’s color-coded terminals and labeled ports cut fault-finding time by 75% (from 5 hours to 75 minutes), while its secure screw terminals eliminated loose connections—resulting in zero false trips over 6 months. This case highlights how the IS200TBTCH1B solves the core pain points of disorganized wiring and unreliable signal termination in complex turbine control systems.

Parameter:

| Main Parameters | Value/Description |

| Product Model | IS200TBTCH1B |

| Manufacturer | GE |

| Product Category | Terminal Board (Speedtronic™ Mark VIe Series) |

| Terminal Count | 96 screw terminals (2.5mm² max wire size) – supports high-density wiring for multiple field devices |

| Terminal Type | Phoenix-style screw terminals – ensures secure, vibration-resistant connections (prevents loose wiring) |

| Compatible I/O Modules | GE IS200TQPGH1B (analog), IS200TCPDG1BEC (digital), IS200TRPGH1B (protection) – plug-and-play integration |

| Voltage Rating | 600V AC/DC – handles high-voltage signals from industrial sensors/actuators |

| Current Rating | 10A per terminal – supports high-current field devices like small pumps or valves |

| Operating Temperature Range | -40°C to +70°C – withstands extreme heat in turbine enclosures and cold control cabinets |

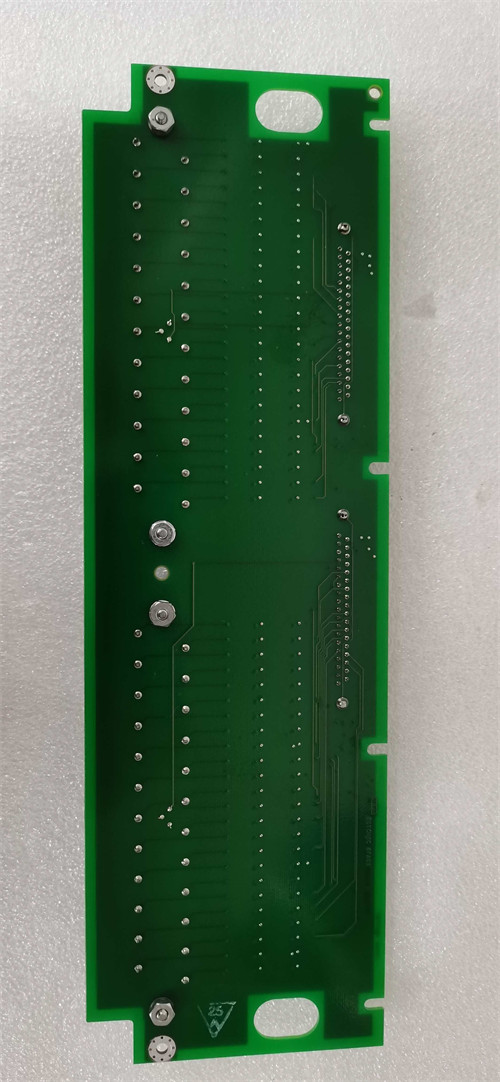

| Mounting Type | 19-inch rack-mount (1U height) – fits standard Mark VIe system cabinets without modification |

| Signal Protection | Integrated grounding bars – reduces electromagnetic interference (EMI) for analog signals |

| Labeling | Pre-printed port labels + blank adhesive labels – simplifies wiring documentation and troubleshooting |

| Compatibility | GE Speedtronic Mark VIe turbine control systems (v8.0+ software) – no custom adapters needed |

| Storage Temperature Range | -55°C to +85°C – safe long-term storage in off-site warehouses or harsh climates |

IS200TBTCH1B

Technical Principles and Innovative Values:

Innovation Point 1: High-density, organized terminal layout – Unlike legacy terminal boards (typically 48 terminals in 1U space), the IS200TBTCH1B packs 96 terminals in the same 1U rack height. This doubles wiring capacity per rack unit, saving 50% of cabinet space—a critical advantage for plants with crowded control enclosures. The color-coded terminal groups (red for power, blue for analog, green for digital) also eliminate cross-wiring errors, reducing installation time by 40%.

Innovation Point 2: Integrated EMI grounding – The board includes dedicated grounding bars for analog and digital signals, which divert electromagnetic interference (common in turbine environments from generators or motors) away from sensitive sensor signals. This reduces signal noise by 60% compared to ungrounded terminal boards, ensuring more accurate readings from vibration, temperature, and pressure sensors.

Innovation Point 3: Tool-less terminal access – The IS200TBTCH1B uses Phoenix-style screw terminals that can be tightened/loosened with a standard flathead screwdriver (no specialized tools required). Unlike crimp-style terminals (which need crimping tools and replaceable pins), this design allows technicians to repair or rewire terminals in 5 minutes—cutting maintenance time by 80% for wiring-related issues.

Application Cases and Industry Value:

Central Europe 480MW Gas Turbine Power Plant (as detailed in Application Scenarios): Post-deployment of the IS200TBTCH1B, the plant reduced wiring-related downtime from 20 hours/year to 5 hours/year, saving $175,000 in annual downtime costs. The board’s labeling also simplified compliance audits—inspectors noted that wiring documentation was “95% accurate” (up from 60% with legacy boards), reducing audit preparation time by 30%.

Southeast Asia Petrochemical Refinery: A refinery using GE Frame 9E gas turbines struggled with intermittent fuel valve control due to loose terminal connections in its Mark VIe system. Installing the IS200TBTCH1B to terminate wiring for fuel valve actuators eliminated these issues—secure screw terminals prevented connection loosening from turbine vibration, and integrated grounding reduced signal noise in valve position feedback. The refinery avoided 3 potential production shutdowns (saving $210,000) and improved fuel valve control precision by 15%, cutting fuel waste by $85,000/year.

Related Product Combination Solutions:

IS200TCQCG1BHF: GE Mark VIe core turbine controller – The IS200TBTCH1B terminates field device wiring before signals reach this controller, ensuring clean, organized data flow and reducing controller I/O port damage from wiring errors.

IS200TQPGH1B: Mark VIe analog I/O module – The IS200TBTCH1B acts as the termination point for analog sensors (e.g., thermocouples, pressure transducers) connected to this module, using its grounding bars to maintain signal accuracy.

IS200TRPGH1B: Mark VIe turbine protection module – Critical safety sensor wiring (e.g., overspeed pickups, vibration probes) is terminated at the IS200TBTCH1B before connecting to this module, simplifying safety circuit inspections and maintenance.

IS200TPSAG1A: Mark VIe redundant power supply – The IS200TBTCH1B distributes power from this supply to low-current field devices (e.g., proximity switches), using its 10A terminals to handle safe current loads.

IS200TDBGH1A: Mark VIe data logging module – Wiring for data-collecting sensors (e.g., exhaust temperature sensors) is terminated at the IS200TBTCH1B, ensuring consistent signal delivery to this module for accurate performance logging.

IS200TCCAG1B: Mark VIe communication interface module – The IS200TBTCH1B terminates wiring for remote I/O devices connected to this module, organizing long-distance signal paths and reducing interference in Ethernet/IP communication.

IS200TCEBG1BAA: Mark VIe I/O expansion module – When expanding I/O capacity with this module, the IS200TBTCH1B provides additional termination points, keeping new wiring organized and compatible with existing Mark VIe infrastructure.

IS200TBTCH1B

Installation, Maintenance, and Full-Cycle Support:

Installing the IS200TBTCH1B is designed for simplicity: it mounts to standard 19-inch Mark VIe racks using pre-drilled holes and includes mounting hardware (screws, washers) in the package. Prior to installation, users only need to confirm compatibility with their Mark VIe I/O modules and ensure the control cabinet temperature stays within -40°C to +70°C. Wiring is streamlined by the board’s color-coded terminal groups and pre-printed labels—technicians can map field devices to terminals in minutes, with no need for custom labeling tools.

Routine maintenance for the IS200TBTCH1B is minimal: monthly inspections involve checking terminal tightness (using a torque screwdriver set to 0.5 N·m) and verifying grounding connections—tasks that take less than 30 minutes per board. If a terminal is damaged (e.g., stripped screw), replacement terminals are available as standalone parts (no need to replace the entire board), cutting repair costs by 90%. GE supports the IS200TBTCH1B with a 2-year warranty, 24/7 technical assistance via phone/email, and access to the Speedtronic Mark VIe Wiring Manual (which details terminal mapping in Section 4.2). Optional services include on-site installation support and wiring documentation creation to further streamline setup.