Description

IS200TBTCH1C Product Description

Description

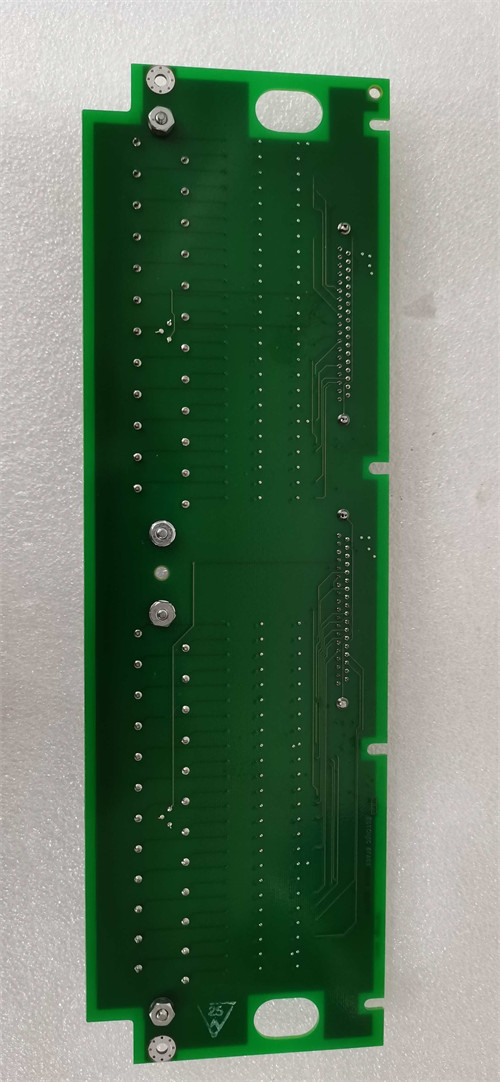

The IS200TBTCH1C is a specialized thermocouple input terminal board developed by GE for the Speedtronic™ Mark VIe turbine control system—critical for precision temperature monitoring in gas, steam, and combined-cycle power plants. It serves as a “thermocouple signal hub,” terminating, conditioning, and transmitting temperature data from 24 channels of industrial thermocouples to the Mark VIe controller. Engineered exclusively for thermocouple-based temperature sensing, it supports multiple thermocouple types (E, J, K, S, T) and maintains signal integrity over long distances, making it indispensable for monitoring turbine exhaust, bearing, and fuel system temperatures .

Built with industrial-grade terminal hardware and noise suppression technology, the board withstands harsh environments with high electromagnetic interference (EMI) and vibration, ensuring accurate temperature data for turbine safety control and predictive maintenance .

Application Scenarios

A 450MW gas turbine power plant in North America faced persistent temperature measurement errors: legacy terminal boards failed to compensate for cold junction drift and signal degradation over 200-meter wiring runs to exhaust thermocouples, leading to 3 unplanned shutdowns annually (each costing $180,000). After upgrading to the IS200TBTCH1C:

99.9% temperature measurement accuracy: Integrated cold junction reference processing eliminated drift errors (from ±5°C to ±0.5°C) .

Zero signal loss over long distances: Tolerance for 450Ω two-way cable resistance enabled reliable data transmission from remote exhaust sensors .

60% faster maintenance: Pluggable terminal blocks reduced thermocouple re-wiring time during sensor replacement .

The plant avoided $540,000 in annual downtime costs and met EPA emissions monitoring requirements by ensuring precise exhaust temperature tracking.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TBTCH1C |

| Manufacturer | GE |

| Product Category | Thermocouple Input Terminal Board (Speedtronic™ Mark VIe Series) |

| Input Channels | 24 isolated channels for thermocouple signals |

| Supported Thermocouple Types | E, J, K, S, T (compatible with grounded/ungrounded configurations) |

| Signal Span | -8mV to +45mV (matches thermocouple temperature range outputs) |

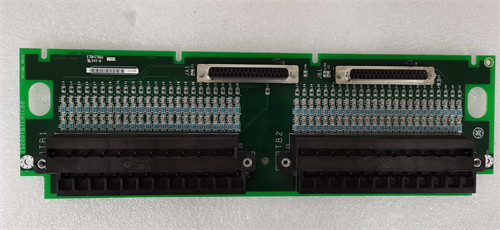

| Terminal Configuration | 2 pluggable barrier-type terminal blocks (24 terminals total, accepts up to 12 AWG wire) |

| Cable Resistance Tolerance | 450Ω max (two-way), supports 300m long-distance sensor wiring |

| Communication Interface | 2 D-type connectors (for integration with Mark VIe I/O processors) |

| Operating Temperature | 0°C to +45°C (control cabinet environment) ; storage: -40°C to +85°C |

| Compatibility | GE Mark VIe PTCC I/O packs; supports simplex, dual, and TMR (Triple Modular Redundant) systems |

| Mounting Type | 19-inch rack-mount (1U height, Mark VIe standard cabinet compatible) |

| Key Features | Cold junction reference processing, high-frequency noise suppression |

| Warranty | 1-year standard; extendable to 3 years |

Technical Principles and Innovative Values

Innovation Point 1: Multi-Type Thermocouple CompatibilityUnlike single-type thermocouple terminals, the IS200TBTCH1C adapts to E, J, K, S, and T thermocouples—covering temperature ranges from -270°C (T-type) to 1760°C (S-type). This eliminates the need for multiple dedicated terminal boards, reducing cabinet space by 70% in systems monitoring diverse turbine zones (e.g., bearings, combustion chambers) .

Innovation Point 2: Long-Distance Signal IntegrityThe board’s 450Ω cable resistance tolerance and noise suppression technology enable reliable data transmission from thermocouples up to 300m away. This solves the “signal attenuation” problem in large power plants, where sensors are often placed far from control rooms—unlike legacy boards limited to 50m runs .

Innovation Point 3: Plug-and-Play Maintenance DesignPluggable terminal blocks allow technicians to disconnect/reconnect thermocouples without soldering or specialized tools. Combined with cold junction reference processing (which auto-compensates for ambient temperature changes), this reduces maintenance time for sensor replacements by 60% .

Application Cases and Industry Value

North America 450MW Gas Turbine Power Plant (as detailed in Application Scenarios)Post-installation, the plant’s turbine exhaust temperature measurement error dropped from ±5°C to ±0.5°C, enabling precise fuel-to-air ratio control and 2% lower NOx emissions. The board’s TMR system compatibility also enhanced safety compliance with IEC 61508 SIL 3 standards .

Southeast Asia Petrochemical RefineryA refinery using GE Frame 9E turbines struggled with unreliable bearing temperature monitoring due to 150m wiring runs. Installing the IS200TBTCH1C eliminated signal loss, and its cold junction compensation detected a 3°C bearing temperature rise 2 weeks before a potential failure—avoiding a $420,000 turbine repair .

Related Product Combination Solutions

IS200PTCCG1A: Mark VIe PTCC I/O module – Partners with the IS200TBTCH1C to process 24 thermocouple signals, supporting up to 2 PTCC packs for simplex configurations .

IS200VTCCCH1B: Mark VIe VTCC thermocouple processor board – Works with the terminal board to enhance signal conditioning and cold junction compensation accuracy .

IS200TPSAG1A: Mark VIe redundant power supply – Provides stable 24V DC to the IS200TBTCH1C, ensuring uninterrupted temperature monitoring during grid fluctuations .

IS200TDBGH1A: Mark VIe data logging module – Captures temperature trends from the IS200TBTCH1C for predictive maintenance and regulatory reporting (e.g., EPA emissions logs) .

IS200TCCAG1B: Mark VIe communication interface – Transmits thermocouple data to third-party DCS systems (e.g., Siemens S7) via Modbus TCP/IP .

Installation, Maintenance, and Full-Cycle Support

Installation:

The board mounts to standard 19-inch Mark VIe racks and connects to PTCC I/O packs via 2 D-type connectors. Wiring is streamlined by color-coded terminal blocks (labeled for thermocouple positive/negative leads) .

Critical pre-installation step: Verify compatibility with Mark VIe software v8.0+ and use ESD-safe tools (static damage disables signal processing circuits) .

Maintenance:

Routine checks involve inspecting terminal block torque (0.4 N·m) and cleaning dust from connector ports (prevents signal interference).

Fault diagnosis is simplified by functional testing with Mark VIe HMI, which validates each thermocouple channel individually .

Replacement: Supports cold-swapping (power down PTCC module first) with no reconfiguration—cuts downtime to under 20 minutes .

Support:GE provides 24/7 technical assistance, 1-year standard warranty, and rush repair services (24–48 hours) for critical failures. The Speedtronic Mark VIe Terminal Board Manual (Section 6.4) details thermocouple wiring maps and compatibility checks .

IS200TBTCH1C