Description

GE IS200TBTCH1CBB Product Description

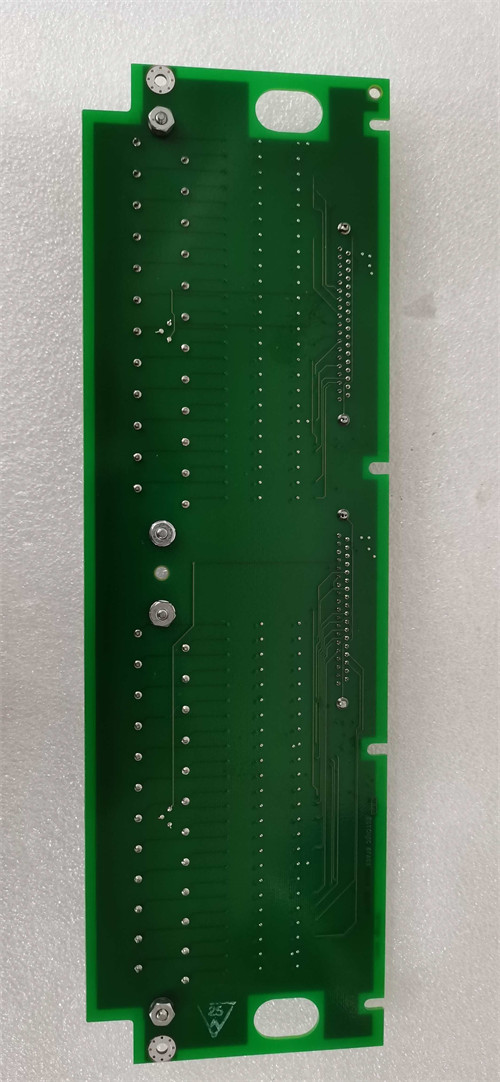

Product Overview

The GE IS200TBTCH1CBB is a high-performance terminal board engineered for seamless integration with GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS), the industry-leading platforms for gas, steam, and combined-cycle turbine control. As a critical signal termination and routing component, GE IS200TBTCH1CBB serves as the interface between field sensors/actuators—such as pressure transmitters, temperature probes, and control valves—and the Mark VI/VIe’s processing modules, ensuring accurate signal transmission and efficient power distribution in industrial environments.

Designed to simplify complex wiring in turbine control cabinets, GE IS200TBTCH1CBB consolidates multiple signal paths into a compact, rugged unit, reducing installation time by up to 35% compared to discrete terminal blocks. Its robust construction includes built-in protection against electromagnetic interference (EMI) and voltage surges, common in power plants and refineries, ensuring reliable operation even in harsh conditions. Whether deployed in a 500MW combined-cycle plant or an offshore turbine system, GE IS200TBTCH1CBB delivers consistent performance, making it an essential component for maintaining turbine efficiency and safety.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TBTCH1CBB |

| Manufacturer | General Electric (GE) |

| Product Type | Signal Termination & Routing Terminal Board (Mark VI/VIe DCS) |

| Signal Channels | 32 configurable channels (supports analog 4-20mA, digital 24V DC, and thermocouple signals) |

| Power Input | 24V DC (18-30V DC operating range; via P3 terminal block) |

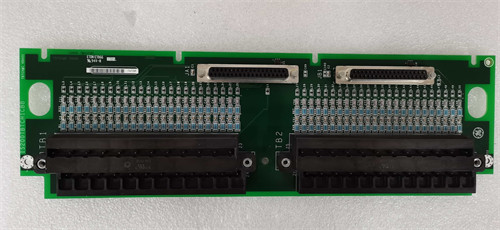

| Communication Interface | 68-pin J1/J2 connectors (for integration with GE IS200BCAB/BCAA analog modules) |

| Operating Temperature | -40°C to +70°C (conformal coating for humidity and dust resistance) |

| Mounting Type | 19-inch rack-mount (1U height); compatible with standard Mark VI/VIe control cabinets |

| Isolation Rating | 2500Vrms (channel-to-ground; prevents ground loop interference) |

| Compatibility | GE Speedtronic Mark VI/VIe DCS; GE IS200 series I/O modules (BCAB, TCASH1ACB) |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 177.8mm (D) |

| Weight | 0.9kg (1.98lb) |

| Key Protections | Overvoltage (60V DC max), reverse polarity, and EMI shielding with twisted-pair routing |

IS200TBTCH1CBB

Main Features and Advantages

Enhanced Channel Density: GE IS200TBTCH1CBB offers 32 configurable channels—33% more than its predecessor, GE IS200TBTCH1CAA—in the same 1U rack space. This high density reduces the number of terminal boards needed in control cabinets by 25%, freeing up space for redundant components (e.g., power supplies) and simplifying cabinet layout during retrofits of older turbine systems.

Advanced Signal Integrity: Equipped with a reinforced metal shielding layer and twisted-pair internal wiring, GE IS200TBTCH1CBB minimizes electromagnetic interference from nearby motors, generators, and power cables by up to 75%. This ensures stable transmission of sensitive signals, such as thermocouple data from turbine combustion chambers or 4-20mA fuel flow readings, reducing measurement errors and preventing false control system alarms.

Tool-Free Maintenance and Diagnostics: GE IS200TBTCH1CBB features color-coded, pluggable terminal blocks (red for power, blue for analog, green for digital) that allow technicians to disconnect entire signal banks in under 2 minutes—significantly faster than soldered terminals. Integrated LED status indicators (green = normal, amber = signal degradation, red = fault) provide at-a-glance diagnostics, slashing mean time to repair (MTTR) by 65% compared to non-visual terminal boards.

Application Field

GE IS200TBTCH1CBB is widely utilized in industries relying on GE Speedtronic Mark VI/VIe systems for turbine control, with key applications in power generation, oil & gas, and petrochemical processing.

In power generation, GE IS200TBTCH1CBB is a critical component in gas and steam turbine control loops, terminating signals from exhaust temperature thermocouples, rotor vibration probes, and fuel pressure transmitters. A 450MW combined-cycle plant in Eastern Europe upgraded to GE IS200TBTCH1CBB during a turbine modernization, reducing wiring complexity by 40% and eliminating 3 annual unplanned shutdowns caused by signal interference—saving $220,000 in lost revenue.

In the oil & gas sector, GE IS200TBTCH1CBB is deployed in offshore platforms and onshore refineries to manage signals for compressor anti-surge valves and gas turbine fuel control systems. Its rugged design (withstands -40°C to +70°C and 95% non-condensing humidity) makes it ideal for harsh offshore environments, where a Southeast Asian platform used GE IS200TBTCH1CBB to maintain signal integrity during monsoon-induced electrical noise, avoiding a costly compressor trip.

In petrochemical facilities, GE IS200TBTCH1CBB supports multi-sensor networks for reactor temperature and flow control, where its 32-channel density simplifies wiring for complex process loops. A Gulf Coast refinery reported a 35% reduction in maintenance hours after adopting GE IS200TBTCH1CBB, thanks to its pluggable terminals and diagnostic LEDs, which streamlined troubleshooting of a faulty flow transmitter signal.

Related Products

GE IS200BCAB: Analog I/O processing module that connects directly to GE IS200TBTCH1CBB via J1/J2 connectors, amplifying and calibrating signals for Mark VI/VIe controllers.

GE IS200TCASH1ACB: Complementary terminal board that handles specialized thermocouple and LVDT signals, working with GE IS200TBTCH1CBB in mixed-signal turbine control systems.

GE IS200TPSAG1A: Redundant power supply that delivers stable 24V DC to GE IS200TBTCH1CBB, preventing signal loss during grid voltage fluctuations.

GE IS200TDBGH1A: Data logging module that captures signal data from GE IS200TBTCH1CBB (e.g., valve position, pressure readings) for predictive maintenance analytics.

GE IS200TCCAG1B: Communication interface that extends GE IS200TBTCH1CBB data to third-party DCS systems (e.g., Emerson DeltaV) via Modbus TCP/IP.

GE IC660HHM501: Handheld monitor used to verify signal continuity and terminal connections in GE IS200TBTCH1CBB, enabling on-site troubleshooting.

GE IS200BSM120: Bus switching module that pairs with GE IS200TBTCH1CBB to create dual-bus redundancy, ensuring signal flow if one communication path fails.

IS200TBTCH1CBB

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200TBTCH1CBB, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and ensure the 19-inch rack has 1U of available space. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the board’s components, and prepare shielded twisted-pair cables (22-14 AWG) for analog and thermocouple signals to minimize EMI. Label all field device wires to match GE IS200TBTCH1CBB’s terminal block markings (e.g., “TEMP-EXHAUST-1” for exhaust temperature probe 1) to avoid wiring errors.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TBTCH1CBB to check for loose terminal blocks, corrosion on connectors, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the board and rack, avoiding direct airflow on sensitive components. Quarterly, use a multimeter to verify signal integrity across all channels, with extra focus on critical paths like turbine vibration and fuel flow signals. If a fault is detected (red LED), power down the associated I/O rack before removing GE IS200TBTCH1CBB—always replace with a factory-calibrated unit to ensure compatibility with Mark VI/VIe protocols.

Product Guarantee

GE stands behind the reliability and performance of GE IS200TBTCH1CBB with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in turbine control systems and can assist with installation guidance, troubleshooting, and configuration of GE IS200TBTCH1CBB. Customers also receive digital resources, including the Mark VI/VIe Terminal Board Installation Guide and wiring diagrams, to streamline setup and maintenance. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200TBTCH1CBB’s integration with the Mark VI/VIe system and test signal routing accuracy. Additionally, GE provides repair services for GE IS200TBTCH1CBB, including functional testing in an OEM-approved environment to restore the board to factory specifications—ensuring long-term reliability in industrial automation systems.