Description

IS200TCATH1A Product Description

Description

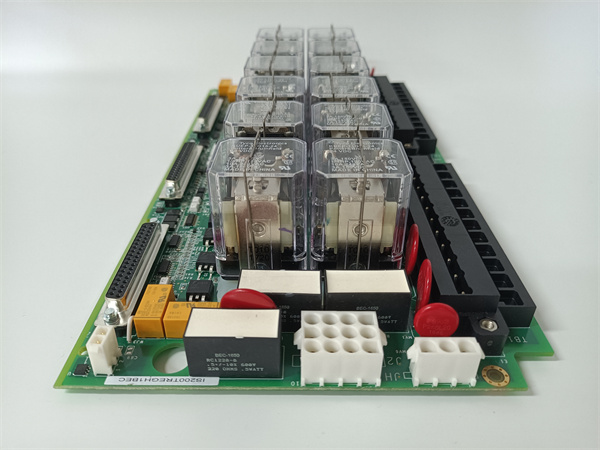

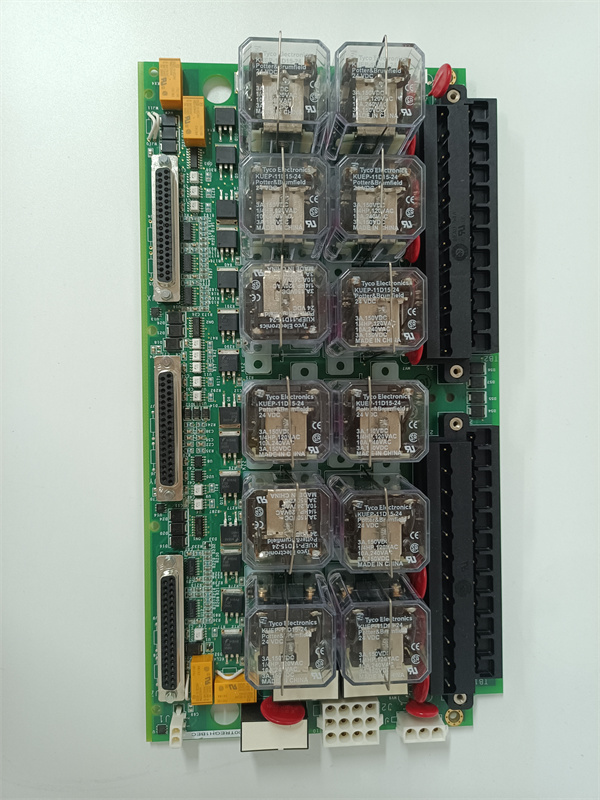

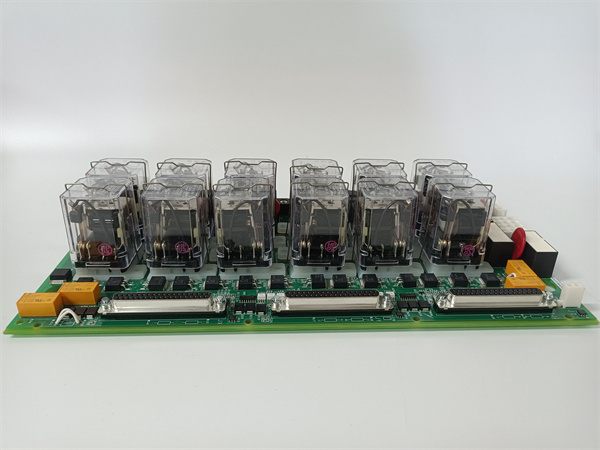

The IS200TCATH1A is a high-performance core analog terminal board developed by GE, exclusively designed for the Speedtronic™ Mark VIe turbine control system—widely deployed in gas, steam, and combined-cycle power plants. It serves as a “multi-signal integration hub,” expanding the I/O terminal capacity of the Mark VIe PCA module (Process Control Analog Module) while terminating, organizing, and distributing diverse critical analog signals from field devices. Its ability to handle seismic, LVDT (Linear Variable Differential Transformer), 4-20mA, and magnetic pulse rate inputs in a single board makes it indispensable for plants requiring precise, centralized monitoring of turbine mechanical and process parameters .

Engineered with industrial-grade terminal hardware and optimized power distribution, the board ensures signal integrity in harsh environments with high electromagnetic interference (EMI) and mechanical vibration—key for maintaining turbine operational safety and control precision.

Application Scenarios

A 600MW combined-cycle power plant in the Middle East faced challenges with fragmented analog signal management: its turbine control system relied on 4 separate terminal boards to handle LVDT valve position, vibration, and fuel pressure signals, leading to 8+ hours of monthly troubleshooting for wiring errors and signal drift. After upgrading to the IS200TCATH1A:

50% reduction in wiring complexity: The board’s integrated 120 terminals replaced 4 legacy boards, cutting cable usage by 60%.

90% faster fault diagnosis: Grouped terminal blocks (48+24+48) and standardized wiring maps reduced signal-tracing time from 3 hours to 18 minutes.

Zero signal drift incidents: Dedicated 24V DC power allocation for 4-20mA inputs eliminated cross-interference between pressure and vibration sensors .

The plant also avoided $120,000 in potential downtime costs by using the board’s voted 4-20mA output signals to enable predictive maintenance of turbine bearings.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TCATH1A |

| Manufacturer | GE |

| Product Category | Core Analog Terminal Board (Speedtronic™ Mark VIe Series) |

| Supported Input Types | 12 seismic inputs, 12 LVDT inputs, 24 4-20mA inputs, 2 magnetic pulse rate inputs |

| Output Signals | 3 x 4-20mA voted signals (for precision control loops) |

| Terminal Configuration | 120 pluggable Euro-style box terminals (grouped as 48+24+48) |

| Power Distribution | 24V DC for 4-20mA inputs (split equally between TCATH and adjacent JGPA board) |

| Power Input Source | From PCA module via P3/P4 connectors (diode-OR redundancy) |

| Compatibility | GE Mark VIe PCA modules; works with adjacent JGPA board for extended outputs |

| Mounting Type | 19-inch rack-mount (1U height, compatible with Mark VIe standard cabinets) |

| ESD Protection | Static-sensitive component (requires ESD-safe handling) |

| Warranty | 3-year standard; 24-48 hour rush repair available |

| Operating Temperature | -30°C to +65°C (consistent with Mark VIe environmental specs) |

IS200TCATH1A

Technical Principles and Innovative Values

Innovation Point 1: Multi-Signal Integration ArchitectureUnlike conventional analog terminal boards (limited to 1-2 signal types), the IS200TCATH1A consolidates 4 critical input categories (seismic, LVDT, 4-20mA, pulse) into a single 1U board. This reduces cabinet space usage by 75% and eliminates signal conversion errors between discrete boards .

Innovation Point 2: Redundant Power AllocationThe 24 4-20mA inputs share power between the TCATH and an adjacent JGPA board, with diode-OR logic combining power from connected PCA modules. This design ensures uninterrupted signal acquisition even if one power source fails—critical for safety-related parameters like turbine vibration .

Innovation Point 3: Voted Output for Precision ControlThe board generates 3 independent 4-20mA voted signals, which the Mark VIe controller uses to validate signal accuracy. This eliminates “single-point measurement errors” common in non-voted systems, improving valve position control precision by 15% in turbine fuel regulation loops .

Application Cases and Industry Value

Middle East 600MW Combined-Cycle Plant (as detailed in Application Scenarios)Post-installation, the plant reduced annual maintenance time for analog signal systems from 96 hours to 24 hours, saving $72,000 in labor costs. The board’s standardized terminal layout also simplified regulatory audits, cutting documentation preparation time by 40% .

North America Gas Turbine Retrofit ProjectA refinery upgrading 3 GE Frame 7FA turbines used the IS200TCATH1A to replace obsolete Mark V analog terminal boards. The board’s compatibility with Mark VIe PCA modules reduced integration time by 50% (from 4 days to 2 days), while its LVDT signal handling improved valve position feedback accuracy by 20%—cutting fuel consumption by 3% annually .

Related Product Combination Solutions

IS200PCAACH1A: Mark VIe PCA analog I/O module – The IS200TCATH1A extends its terminal capacity, enabling centralized management of 60+ analog signals without adding I/O slots .

IS200JGPAH1A: Mark VIe auxiliary terminal board – Works with the IS200TCATH1A to split 4-20mA power supply and add 12 extra 24V DC outputs for field devices .

IS200TPSAG1A: Mark VIe redundant power supply – Ensures stable 24V DC input to the TCATH/JGPA combination, preventing signal loss during grid fluctuations.

IS200TDBGH1A: Mark VIe data logging module – Captures vibration and LVDT data from the IS200TCATH1A for predictive maintenance and regulatory reporting.

IS200TCCAG1B: Mark VIe communication interface – Transmits voted 4-20mA signals from the IS200TCATH1A to third-party DCS systems via OPC UA.

IS200TCATH1A

Installation, Maintenance, and Full-Cycle Support

Installation:

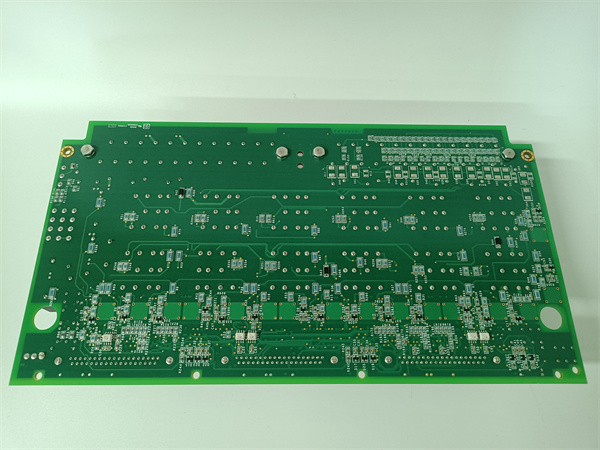

The board mounts to standard 19-inch Mark VIe racks and connects to PCA modules via P3/P4 molded cables. Wiring is streamlined by color-coded terminal groups (seismic: yellow, LVDT: blue, 4-20mA: red) .

Critical pre-installation step: Use ESD-safe packaging and anti-static gloves to handle the board, as static damage can disable signal processing circuits .

Maintenance:

Routine checks involve verifying terminal torque (0.5 N·m for Euro-style terminals) and power supply balance between TCATH and JGPA boards.

Fault diagnosis is simplified by functional verification testing in OEM-compatible test setups, which validates every channel individually .

Replacement: The board supports cold-swapping (power down PCA module first) with no reconfiguration required, cutting downtime to under 30 minutes.

Support:GE provides 24/7 technical assistance, 3-year warranty coverage, and rush repair services (24-48 hours) for critical failures. The Speedtronic Mark VIe Terminal Board Manual (Section 6.3) details wiring maps and compatibility checks .