Description

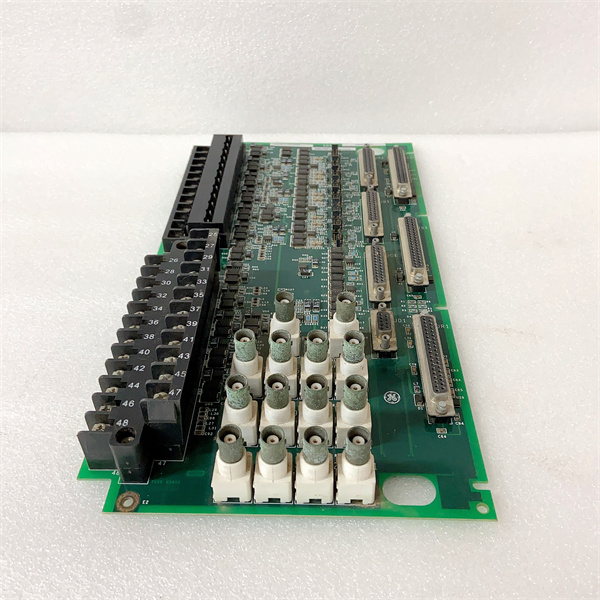

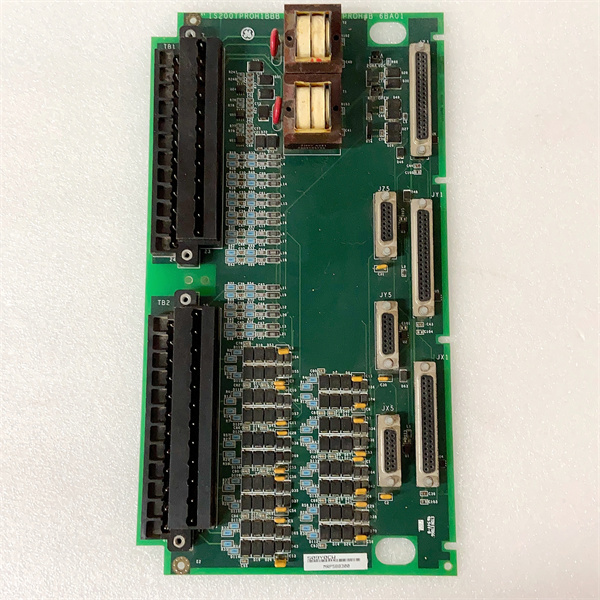

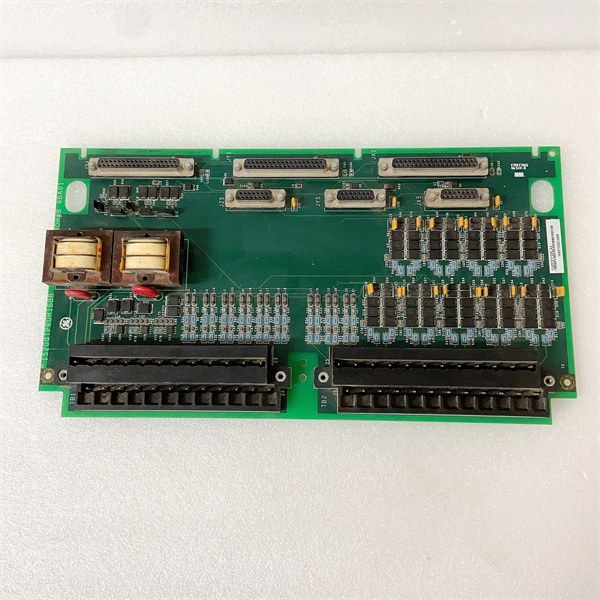

IS200TCATH1ABA: High-Precision Analog I/O Module for Gas Turbine Control

The IS200TCATH1ABA is a critical component of GE’s Mark V and Mark VIe Speedtronic gas turbine control systems, designed to monitor and manage temperature, vibration, and process signals with exceptional accuracy and reliability. This module serves as the interface between the turbine’s field sensors (e.g., thermocouples, LVDTs) and the central control system, ensuring safe and efficient operation in power generation, oil & gas, and industrial applications.

Key Functions & Features

Multi-Signal Processing

Temperature Monitoring: Supports up to 16 thermocouple inputs (types J, K, T, E) for real-time temperature tracking of critical components like combustion chambers and bearings.

Analog I/O: Processes 4–20 mA signals for fuel flow, pressure, and compressor stall detection, with configurable current ranges (20 mA or 200 mA) via hardware jumpers (J5/J6).

Vibration & Position Sensing: Integrates ±10 V DC inputs for vibration analysis and LVDT (linear variable differential transformer) signals to monitor shaft position.

Alarm & Trip Handling

Threshold Detection: Generates alarms when parameters exceed safe limits (e.g., high-temperature warnings) and initiates emergency trips to shut down the turbine if critical thresholds are breached.

Redundant Protection: Features dual-channel signal processing and self-diagnostic capabilities to ensure fail-safe operation in harsh environments.

Communication & Integration

Bus Connectivity: Communicates with the Mark V/VIe system via the COREBUS (3PL connector) and interfaces with other modules like TCQA (analog signal conditioning) and TBQC (terminal boards).

Modular Design: Mounts directly onto the turbine’s I/O rack, simplifying integration with existing GE control infrastructure.

Technical Specifications

| Parameter | Value/Description |

| Manufacturer | General Electric (GE) |

| Series | Mark V/Mark VIe |

| Input Types | Thermocouples (J/K/T/E), 4–20 mA, LVDT, ±10 V DC vibration signals |

| Output Types | 4–20 mA analog outputs, digital relay trips, and alarm signals |

| Power Supply | 24V DC (±10%) |

| Operating Temperature | -40°C to +70°C (with conformal coating for harsh environments) |

| Resolution | 12-bit for analog signals |

| Communication | Proprietary GE COREBUS protocol |

| Dimensions | 150 mm × 240 mm × 350 mm (compact DIN rail or rack-mounted design) |

IS200TCATH1ABA

Applications & Industry Impact

Power Generation

Case Study: A 500 MW combined-cycle power plant in the Middle East reduced unplanned downtime by 30% after upgrading to the IS200TCATH1ABA. The module’s precise temperature monitoring eliminated thermal stress-related failures in the combustion chamber, improving overall system efficiency by 1.2%.

Oil & Gas

Case Study: An offshore platform using GE’s Mark VIe system integrated the IS200TCATH1ABA to monitor compressor vibration. The module’s real-time analysis reduced maintenance costs by $250,000 annually by detecting bearing wear before catastrophic failure.

Industrial Processes

Steel Manufacturing: In a blast furnace application, the IS200TCATH1ABA stabilized temperature control, cutting energy consumption by 8% and extending the lifespan of refractory linings.

Installation & Maintenance

Setup

Mounting: Install on a DIN rail or turbine control rack using M3 screws (torque to 0.5 N·m).

Wiring: Use twisted-pair cables for analog signals and shielded cables for thermocouples to minimize noise interference. Connect to the COREBUS via the 3PL connector and terminal boards (e.g., TBQA, TBQC).

Configuration

Jumpers: Configure current ranges (J5/J6) and enable diagnostic testing (J7 for RS232 port access).

Software: Calibrate signals and set thresholds using GE’s Proficy Machine Edition or Mark VIe programming tools.

Maintenance

Routine Checks: Inspect connectors for corrosion and verify signal integrity using the module’s LED status indicators.

Repairs: Replace faulty modules with factory-calibrated units or utilize GE’s repair services, which include functional testing in an OEM system setup.

IS200TCATH1ABA

Compatibility & Redundancy

Modules: Works seamlessly with TCQA (analog signal conditioning), TBQB (terminal boards), and STCA (system timing and communication).

Redundancy: Pair with IS200BSM120 bus switching modules to create dual-bus architectures, ensuring uninterrupted operation during maintenance or component failure.

Conclusion

The IS200TCATH1ABA is a cornerstone of GE’s gas turbine control systems, delivering precision, reliability, and flexibility for mission-critical applications. Its ability to process diverse analog signals, enforce safety protocols, and integrate with GE’s ecosystem makes it indispensable for optimizing turbine performance, reducing downtime, and enhancing operational efficiency. For advanced power generation and industrial processes, the IS200TCATH1ABA ensures that temperature, vibration, and process parameters are managed with unmatched accuracy.