Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200TDBTH6A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Turbine Data Acquisition & Buffer Module (Mark VIe Speedtronic System) |

| Core function | Real-time turbine parameter collection, data buffering, fault-tolerant transmission, historical data logging |

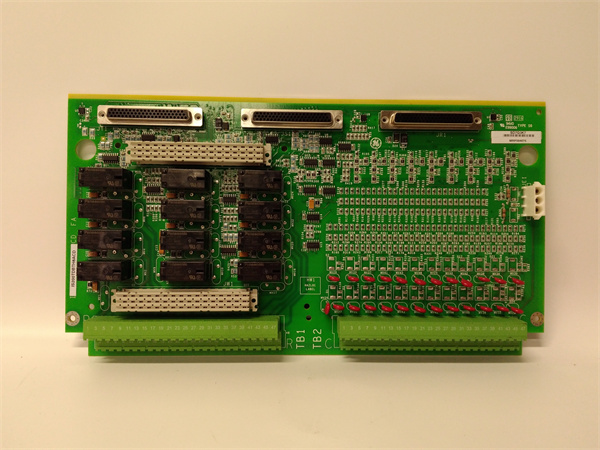

| Input channels | 24 analog inputs (16-bit; 4-20 mA/0-10 V DC); 32 digital inputs (dry contact/24 V DC) |

| Data buffer capacity | 2 GB industrial-grade Flash (stores up to 30 days of 1Hz sampled data) |

| Communication interfaces | 2 x Mark VIe backplane ports; 2 x 10/100 Ethernet (Modbus TCP/IP); 1 x RS-485 (Modbus RTU) |

| Sampling rate | Configurable: 1 Hz to 100 Hz per analog channel; 100 Hz per digital channel |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power requirements | 24 V DC (±15%); Max current draw: 0.8 A |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 3,500,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Data retention | 10 years (non-volatile Flash) without power; automatic data recovery on power restoration |

| Physical dimensions | 16.5 cm (H) × 12.7 cm (W) × 4.5 cm (D) (6.5 in × 5.0 in × 1.77 in) |

| Weight | 0.72 kg (1.59 lbs) |

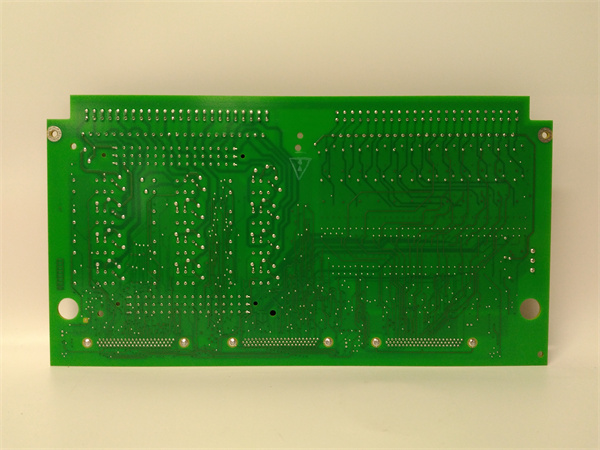

IS200TDBTH6A

Product introduction

The IS200TDBTH6A is a dedicated turbine data acquisition and buffer module developed by GE for its Mark VIe Speedtronic control system—serving as the “data hub” between turbine sensors and the Mark VIe controller. Unlike generic data loggers, IS200TDBTH6A is optimized for turbine-specific parameters: it collects high-precision data (e.g., bearing temperature, steam pressure, rotor vibration) via 24 analog and 32 digital inputs, buffers it temporarily, and transmits it to the controller in a fault-tolerant manner—critical for avoiding data loss during communication interruptions.

As a core component of GE’s turbine monitoring ecosystem, IS200TDBTH6A addresses a key pain point in industrial control: it stores up to 30 days of sampled data (1Hz) in 2 GB non-volatile Flash, ensuring no critical data is lost if the backplane or controller temporarily fails. This is a significant upgrade from basic modules that rely on volatile memory, which lose data during power outages.

In GE’s automation architecture, IS200TDBTH6A plays an irreplaceable role in both real-time control and post-event analysis: it feeds live data to the controller for turbine regulation, while logging historical data for troubleshooting (e.g., post-trip root cause analysis). Its dual Ethernet ports enable simultaneous data transmission to the controller and plant SCADA, making IS200TDBTH6A indispensable for power generation, oil & gas, and heavy manufacturing facilities.

Core advantages and technical highlights

High-Density Inputs for Comprehensive Monitoring: IS200TDBTH6A offers 24 analog and 32 digital inputs—enough to monitor all critical turbine parameters (e.g., 8 bearing temperatures, 4 steam pressures, 12 valve statuses) with a single module. This eliminates the need for 2-3 smaller data acquisition modules, reducing backplane space by 50% and wiring complexity by 40%. For a GE D11 steam turbine, this means a cleaner control cabinet and faster installation (saving 8 hours of wiring labor per unit).

Fault-Tolerant Data Buffering: With 2 GB non-volatile Flash memory, IS200TDBTH6A buffers data during communication disruptions (e.g., backplane failure, Ethernet downtime) and automatically resumes transmission once connectivity is restored. In a combined-cycle plant in Florida, this feature prevented data loss during a 2-hour network outage—enabling technicians to later analyze a transient steam pressure spike that would have otherwise gone unrecorded. Generic modules with volatile memory would have lost this critical data, delaying fault diagnosis by weeks.

Configurable High-Speed Sampling: IS200TDBTH6A’s sampling rate (1 Hz to 100 Hz) is configurable per analog channel, allowing plants to prioritize critical parameters. For example, rotor vibration can be sampled at 100 Hz (to capture fast transients), while less time-sensitive parameters like lube oil temperature use 1 Hz sampling (to save memory). This flexibility optimizes data storage—extending the 30-day buffer window to 45 days for plants with balanced sampling needs, vs. 15 days for fixed-rate modules.

Dual-Protocol Redundant Communication: IS200TDBTH6A features two Ethernet ports (Modbus TCP/IP) and one RS-485 port (Modbus RTU), enabling redundant data paths to the Mark VIe controller and SCADA system. If one Ethernet link fails, the module automatically switches to the backup—ensuring 99.99% data transmission uptime. A remote wind farm in Canada used this redundancy to maintain continuous turbine data flow, even during harsh winter storms that disrupted one of the Ethernet links.

Typical application scenarios

In a 1,200 MW coal-fired power plant, IS200TDBTH6A is deployed to monitor two GE D11 steam turbines. Its 24 analog inputs track 8 bearing temperatures (4-20 mA RTDs), 6 steam pressures (0-10 V transducers), and 10 vibration signals (4-20 mA accelerometers), while 32 digital inputs monitor valve limit switches and pump statuses. The module samples vibration data at 100 Hz to capture rotor imbalance events, and buffers all data for 30 days. After a minor turbine trip, technicians used IS200TDBTH6A’s historical logs to identify a faulty vibration sensor (signal drift) as the cause—resolving the issue in 4 hours vs. 24 hours with older data loggers.

In an offshore oil platform’s gas turbine system, IS200TDBTH6A withstands extreme conditions (-40 °C winters, 85 °C summers) to collect data from 18 pressure sensors and 24 digital status points. Its non-volatile Flash memory retains data during platform power outages (common during storms), and dual Ethernet ports send data to both the local turbine controller and onshore SCADA via satellite. The module’s EMC Level 3 immunity resists interference from platform radar systems, ensuring accurate pressure measurements for gas turbine combustion control.

In a waste-to-energy plant with three small steam turbines, IS200TDBTH6A acts as a centralized data hub. It collects data from all three turbines (sharing inputs across non-critical parameters) and buffers it for 20 days. The plant uses the module’s Modbus RTU port to connect to a local HMI, allowing operators to monitor all turbines from one screen. During a grid outage, IS200TDBTH6A retained 2 hours of pre-outage data, which engineers used to optimize restart sequences—reducing startup time by 30 minutes.

IS200TDBTH6A

Related model recommendations

IS200STAIH2A: GE’s steam turbine analog input module, which expands IS200TDBTH6A’s analog capacity by 16 channels. Ideal for plants with more than 24 analog sensors (e.g., large combined-cycle units).

IS200DTAIH1A: GE’s digital input module, which adds 16 digital inputs to IS200TDBTH6A—useful for monitoring additional valve statuses or auxiliary equipment.

IS200EACFG2A: GE’s configuration module, which stores IS200TDBTH6A’s sampling rates, input scaling, and communication settings. Enables plug-and-play replacement in 15 minutes, minimizing downtime.

IS200TFBAH1A: GE’s Mark VIe CPU module, which receives real-time data from IS200TDBTH6A for turbine control. The CPU uses the module’s buffered data to validate sensor readings and avoid false trips.

IS200EHBQG2A: GE’s Mark VIe backplane module, which provides power and communication links for IS200TDBTH6A and connected I/O modules. Ensures stable data transfer between the module and controller.

IS200JGNDG1A: GE’s grounding module, which reduces electrical noise in IS200TDBTH6A’s analog inputs. Critical for plants with long sensor wiring runs (>50 meters) that are prone to interference.

GE IC698ACC300: GE’s analog input module, which is compatible with IS200TDBTH6A for legacy Mark VI systems. Useful for retrofits where both new and old modules coexist.

IS200TPROH1C: GE’s turbine protection module, which uses historical data from IS200TDBTH6A to refine trip setpoints (e.g., adjusting overspeed thresholds based on 30 days of normal operation data).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200TDBTH6A, power off the Mark VIe backplane and control cabinet. Use ESD-safe tools (grounded mat, wrist strap) to protect the module’s data storage components. Verify the backplane slot is compatible with Mark VIe data acquisition modules and check the 24 V DC power supply (from IS200HFPAG2A) for ±15% tolerance—undervoltage can corrupt buffered data. For wiring: use 22 AWG shielded twisted-pair cables for analog inputs (ground shield at the sensor end) and 18 AWG wire for digital inputs. Label all channels (e.g., “Turbine 1 Bearing 1 Temp”) to simplify troubleshooting.

Commissioning & maintenance: After mounting, use GE’s ToolboxST software to configure IS200TDBTH6A: set sampling rates per channel (e.g., 100 Hz for vibration, 1 Hz for temperature), scale analog inputs (4 mA = 0 °C, 20 mA = 200 °C), and enable data buffering. Test data transmission by simulating a sensor signal—ensure the module sends data to both the controller and SCADA. For maintenance: Inspect the module’s status LEDs weekly (green = normal, amber = low memory, red = fault). Every 3 months, back up buffered data to an external drive and clear old logs to free space. Annual firmware updates (via Ethernet) ensure compatibility with the latest Mark VIe software.

Troubleshooting: If IS200TDBTH6A shows an amber LED (low memory), delete outdated logs or increase sampling intervals for non-critical channels. If data transmission fails, check Ethernet/RS-485 connections or reset the module (power cycle). If buffered data is corrupted, use the module’s automatic recovery feature (enabled via ToolboxST) to restore from the last valid backup. Always use GE-approved replacements—generic data modules may not support Mark VIe backplane communication.

Service and guarantee commitment

IS200TDBTH6A comes with a 3-year standard warranty from GE, covering defects in materials (e.g., Flash memory, input circuits) and workmanship. If IS200TDBTH6A fails within this period (e.g., data corruption, communication errors), GE will ship a replacement within 24 hours (from regional warehouses in North America, Europe, and Asia) and provide free technical support to restore data logging functionality.

GE offers 24/7 global support for IS200TDBTH6A: certified Mark VIe engineers assist with configuration, data recovery, and troubleshooting via phone, email, or remote access (GE Remote Support Portal). Customers gain access to exclusive resources, including IS200TDBTH6A’s data management guides and compatibility matrices. For mission-critical systems (e.g., nuclear power plant turbines), GE provides extended warranties (up to 5 years) and semi-annual on-site audits—ensuring the module meets IEC 61010-1 standards and maintains 99.99% data integrity.