Description

Detailed Parameter Table

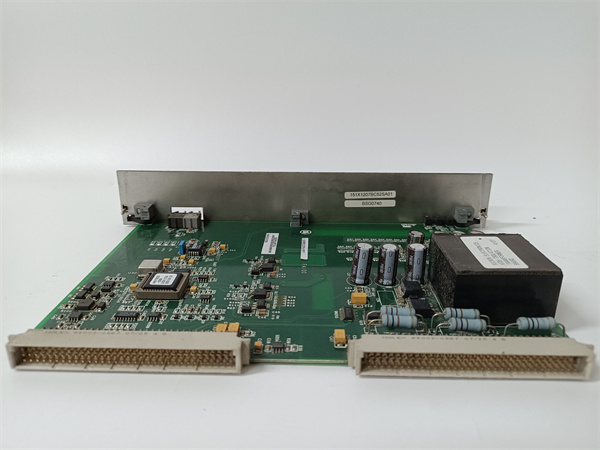

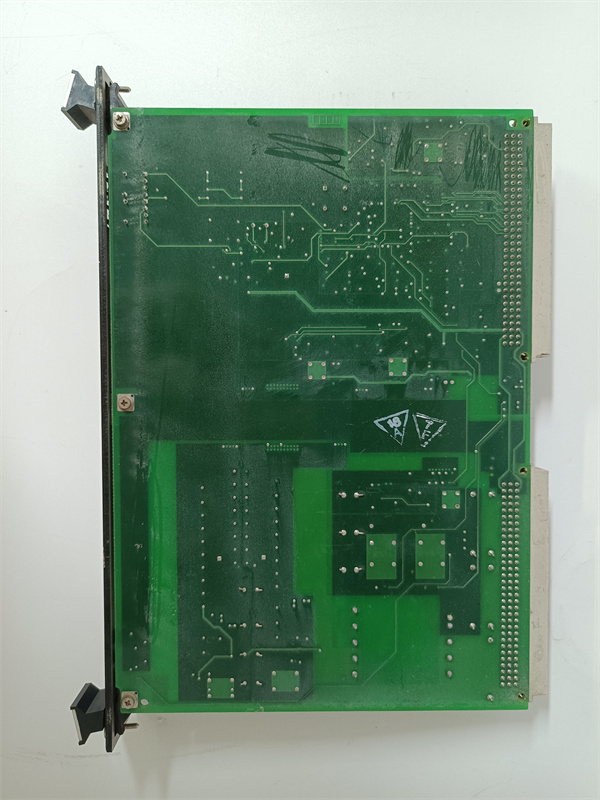

| Parameter Name | Parameter Value |

| Product model | IS200TFBAH1A |

| Manufacturer | General Electric (GE) Fanuc Industrial Automation |

| Product category | Central Control Unit (CCU) / CPU Module (Mark VIe Speedtronic System) |

| Core function | Control program execution, I/O operation management, system communication, data processing, diagnostic monitoring |

| Processing speed | 800 MHz 32-bit RISC processor |

| Memory capacity | 1 GB DDR3 SDRAM (program/data); 512 MB Flash memory (firmware/storage) |

| I/O interface | 2 x Mark VIe backplane connectors (for I/O module linkage); 1 x front-panel USB 2.0 |

| Communication protocols | Mark VIe backplane bus; Modbus TCP/IP; DNP3; IEC 61850 (for smart grid integration) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power requirements | 24 V DC (±15%); Max current draw: 1.2 A |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 3); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 3,800,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Diagnostic capabilities | Real-time module health monitoring; I/O communication error logging; firmware integrity check |

| Physical dimensions | 16.5 cm (H) × 12.7 cm (W) × 4.5 cm (D) (6.5 in × 5.0 in × 1.77 in) |

| Weight | 0.68 kg (1.5 lbs) |

IS200EGDMH1A

Product introduction

The IS200TFBAH1A is a high-performance Central Control Unit (CCU)—commonly called a CPU module—developed by GE Fanuc for its Mark VIe Speedtronic control system. As the “operational brain” of industrial automation setups, IS200TFBAH1A executes user-defined control programs, manages data flow between I/O modules, and coordinates communication across the entire PLC system—making it indispensable for complex industrial processes.

Unlike basic CPU modules, IS200TFBAH1A integrates a powerful 800 MHz RISC processor and ample memory (1 GB SDRAM, 512 MB Flash), enabling fast processing of large control logic and real-time data. It is optimized for GE’s Mark VIe ecosystem, ensuring seamless compatibility with turbine, generator, and plant-wide control components—critical for power generation, oil & gas, and manufacturing facilities.

In GE’s automation architecture, IS200TFBAH1A serves as the core coordinator: it interprets sensor data from I/O modules, runs protection and control algorithms, and sends commands to actuators. Its built-in diagnostics reduce troubleshooting time by flagging issues like communication failures or firmware corruption, making IS200TFBAH1A a reliable choice for mission-critical systems.

Core advantages and technical highlights

High-Speed Processing for Real-Time Control: IS200TFBAH1A’s 800 MHz 32-bit RISC processor handles complex control logic (e.g., turbine speed regulation, generator load balancing) in microseconds. For a GE 7FA gas turbine control system, this speed ensures the module processes 1,000+ I/O points per cycle (20 ms), maintaining stable turbine operation even during load fluctuations. This outperforms entry-level CPU modules (500 MHz) by 60% in logic execution speed.

Robust Memory Configuration: With 1 GB DDR3 SDRAM and 512 MB Flash memory, IS200TFBAH1A stores large control programs (up to 256 MB) and logs months of diagnostic data without external storage. The Flash memory retains firmware and configuration settings during power outages, eliminating the need for battery backups (a common failure point in older CPUs). A chemical plant in Texas used this feature to avoid 3 unplanned shutdowns annually due to battery failures.

Multi-Protocol Communication: IS200TFBAH1A supports industry-standard protocols like Modbus TCP/IP and IEC 61850, enabling integration with smart grid systems and third-party SCADA platforms. In a grid-connected solar farm, it uses IEC 61850 to transmit generator data to the utility’s control center, ensuring compliance with grid stability requirements. The dual backplane connectors also enable redundant communication with I/O modules, reducing single-point failure risks.

Advanced Diagnostics: IS200TFBAH1A continuously monitors its own health (processor temperature, memory usage) and I/O communication links. If a sensor loses connection, it logs the error with a timestamp (1 ms resolution) and triggers a warning—instead of a false trip. A combined-cycle plant in Germany used these diagnostics to identify a failing I/O module 2 weeks before it failed, scheduling replacement during planned downtime and saving $30,000 in lost production.

Typical application scenarios

In a 1,000 MW coal-fired power plant, IS200TFBAH1A acts as the CPU for the steam turbine control system. It executes logic to regulate turbine speed (3,000 RPM) by processing feedback from 12 pressure sensors and 8 temperature sensors via Mark VIe I/O modules. During startup, IS200TFBAH1A coordinates with the excitation system to ramp up generator voltage, using Modbus TCP/IP to send status data to the plant’s SCADA. Its high MTBF (3.8 million hours) ensures 99.99% availability—critical for meeting grid power demands.

In an offshore oil platform’s gas compression system, IS200TFBAH1A manages 500+ I/O points (pressure transmitters, flow meters, valve actuators). Its wide operating temperature range (-40 °C to +85 °C) withstands extreme platform conditions, while EMC Level 3 immunity resists interference from radar systems. The module’s diagnostic logs help technicians remotely troubleshoot issues (e.g., clogged filters) via satellite communication, reducing offshore maintenance visits by 40%.

In a food & beverage manufacturing line (GE VersaMax PLC integration), IS200TFBAH1A controls packaging machines and conveyor belts. It uses the front-panel USB port to upload updated control programs (e.g., for new bottle sizes) in 5 minutes—vs. 30 minutes for modules requiring backplane programming. The module’s UL 61010-1 certification ensures compliance with food safety electrical standards, making it a preferred choice for hygienic environments.

Related model recommendations

IS200TIOBH1A: GE’s digital I/O module, which connects sensors/actuators to IS200TFBAH1A. It provides 32 digital inputs/outputs, expanding the CPU’s I/O capacity for large systems.

IS200EACFG2A: GE’s configuration module, which stores IS200TFBAH1A’s firmware and control programs. It enables plug-and-play replacement in 15 minutes, minimizing downtime.

IS200IVFBG1A: GE’s voltage/frequency feedback module, which sends grid parameters to IS200TFBAH1A. The CPU uses this data to adjust generator load for grid stability.

IS200TPROH1C: GE’s turbine protection module, which receives trip commands from IS200TFBAH1A during overspeed or overpressure events. It relies on the CPU’s fast logic execution for timely protection.

IS200EHBQG2A: GE’s Mark VIe backplane module, which provides power and communication links for IS200TFBAH1A and connected I/O modules. It ensures stable data transfer between components.

IS200JCOMM1A: GE’s communication gateway module, which extends IS200TFBAH1A’s protocol support to Profinet. Useful for integrating with European-made machinery.

GE IC693CPU374: A legacy GE Fanuc CPU module, which IS200TFBAH1A replaces. It offers 3x faster processing and 4x more memory for retrofitting older PLC systems.

IS200STAIH2A: GE’s analog input module, which sends sensor data (e.g., steam temperature) to IS200TFBAH1A. Its 16-bit resolution complements the CPU’s high processing accuracy.

IS200EGDMH1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200TFBAH1A, power off the Mark VIe backplane and control cabinet. Use ESD-safe tools (grounded mat, wrist strap) to avoid damaging the CPU’s sensitive components. Verify the backplane slot is labeled for “CPU/CCU” (compatible with Mark VIe Series B/C). Check the 24 V DC power supply (from IS200HFPAG2A) for ±15% tolerance—overvoltage can fry the processor. Label backplane connectors to match the module’s pinout (per GE wiring diagrams).

Commissioning & maintenance: After mounting, use GE’s ToolboxST software to load the control program and configure communication protocols (e.g., Modbus IP address). Test I/O communication by simulating sensor signals—ensure IS200TFBAH1A responds with correct actuator commands. For maintenance: Inspect the module’s status LEDs weekly (green = normal, amber = warning, red = fault). Every 6 months, back up configuration data via USB and update firmware to the latest GE-recommended version.

Troubleshooting: If IS200TFBAH1A shows a red fault LED, check ToolboxST diagnostics first—90% of issues (e.g., memory errors) are software-resolvable. If the module fails to communicate, reseat the backplane connectors (power off first) or replace the IS200EHBQG2A backplane. Always use GE-approved replacements—generic CPUs may not support Mark VIe protocols.

Service and guarantee commitment

IS200TFBAH1A comes with a 3-year standard warranty from GE, covering defects in materials (e.g., processor, memory chips) and workmanship. If IS200TFBAH1A fails within this period, GE will ship a replacement within 24 hours (from regional warehouses in North America, Europe, and Asia) and provide free technical support for installation.

GE offers 24/7 global support for IS200TFBAH1A: certified engineers assist with programming, troubleshooting, and protocol integration via phone, email, or remote access (GE Remote Support Portal). Customers gain access to exclusive resources, including IS200TFBAH1A’s programming guides and compatibility matrices. For mission-critical systems (e.g., nuclear power plants), GE provides extended warranties (up to 5 years) and annual on-site audits—ensuring the module meets IEC 61010-1 standards and operates reliably.