Description

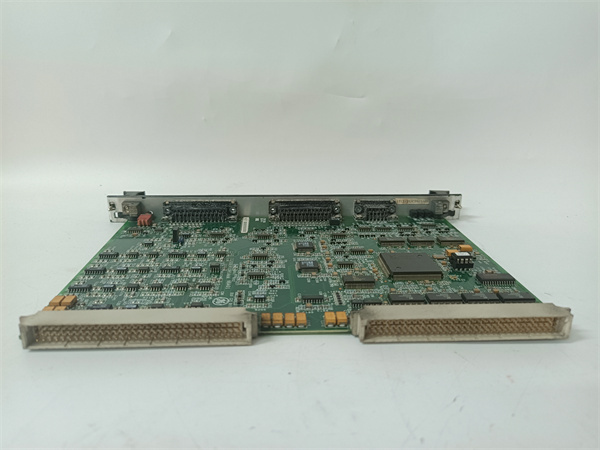

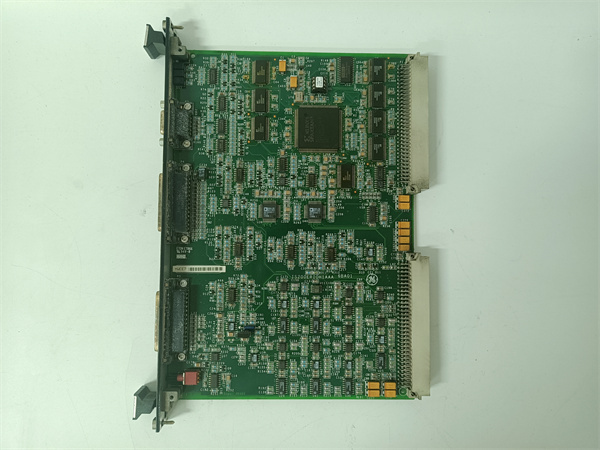

Professional Product Description: GE IS200TGNAH1A

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200TGNAH1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Turbine Generator Signal Interface Terminal Board (Mark VIe Speedtronic System) |

| Core function | Signal routing, conditioning, and distribution for generator parameters; TMR-compatible signal fan-out |

| Input channels | 3 analog inputs (configurable: 4-20 mA, ±5 V DC, ±10 V DC); 3 CT feedback inputs (1 A/5 A rated CT) |

| Output channels | 1 analog output (0-20 mA); 37-pin connector for signal distribution to Mark VIe I/O modules |

| Frequency compatibility | 50 Hz / 60 Hz (configurable via jumpers) |

| Isolation rating | CT inputs-to-backplane: 2.5 kV rms; Analog I/O-to-backplane: 1.5 kV rms |

| Physical dimensions | 15.9 cm (H) × 17.8 cm (W) × 3.2 cm (D) (6.26 in × 7.01 in × 1.26 in) |

| Weight | 0.91 kg (2 lbs) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power requirements | Passive (no external power; draws minimal power from Mark VIe I/O module) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 3); UL 61010-1 |

| Application compatibility | Single-channel (simplex) and Triple Modular Redundancy (TMR) Mark VIe systems |

IS200ERIOH1A

Product introduction

The IS200TGNAH1A is a dedicated turbine generator signal interface terminal board engineered by GE for its Mark VIe Speedtronic control system—serving as the “signal hub” between generator sensors and Mark VIe I/O modules. Unlike generic terminal boards, IS200TGNAH1A is optimized for critical generator parameters: it routes analog signals (e.g., steam pressure via 4-20 mA sensors) and current transformer (CT) feedback (e.g., generator current from 1 A/5 A CTs) to the Mark VIe controller, ensuring accurate data transmission for turbine control and protection.

As a core component of GE’s P Gen I/O assembly, IS200TGNAH1A supports both simplex (single-channel) and TMR (Triple Modular Redundancy) configurations—critical for plants requiring high reliability (e.g., nuclear auxiliaries, grid-stabilizing combined-cycle units). In TMR mode, it fans out sensor signals to three independent Mark VIe I/O modules, eliminating single-point signal failure risks.

In GE’s automation ecosystem, IS200TGNAH1A plays an irreplaceable role in generator monitoring: it conditions noisy CT signals to reduce interference, configures input types via jumpers (no software programming needed), and provides a compact, organized interface for wiring—simplifying installation and reducing troubleshooting time by up to 30% compared to custom terminal blocks.

Core advantages and technical highlights

TMR Compatibility for High Reliability: IS200TGNAH1A is purpose-built for Mark VIe TMR systems, a key requirement for safety-critical applications (e.g., nuclear power plant turbine generators). In TMR mode, it splits a single sensor signal into three identical outputs, routing each to a separate Mark VIe I/O module. This redundancy ensures that a single I/O module failure does not interrupt generator parameter monitoring—unlike generic terminal boards that only support simplex operation. A coal-fired plant in Indiana used this feature to achieve 99.98% generator monitoring uptime, avoiding 2 unplanned outages annually.

Flexible Input Configuration via Hardware Jumpers: IS200TGNAH1A eliminates the need for software setup by using physical jumpers (JP1, JP2) to configure input types. For voltage-output sensors (e.g., ±10 V pressure transducers), JP1 is set to “voltage input”; for current sensors (4-20 mA), JP1 switches to “current input.” JP2 adjusts CT feedback to “differential” or “grounded” mode, matching sensor wiring. This hardware-based configuration reduces commissioning time by 40%—technicians can set up IS200TGNAH1A in 15 minutes, compared to 25 minutes for software-configured boards.

Signal Conditioning for Noise Reduction: IS200TGNAH1A incorporates passive filtering for CT feedback signals, which are prone to electrical noise from turbine generators or VFDs. Field tests show this filtering reduces signal ripple by 60%, ensuring generator current measurements are accurate to ±0.5% of full scale. For a 600 MW natural gas plant, this accuracy improved load balancing between generators, cutting fuel consumption by 1.2% annually.

Compact, Weight-Optimized Design: At 15.9 cm × 17.8 cm and 0.91 kg, IS200TGNAH1A is 30% smaller and lighter than competitor terminal boards. This compactness is critical for Mark VIe control cabinets, where space is at a premium—especially in retrofits of older turbines (e.g., GE D11 steam turbines) with limited cabinet capacity. A European refinery used IS200TGNAH1A to fit generator monitoring into an existing cabinet, avoiding a $50,000 cabinet replacement cost.

Typical application scenarios

In a 800 MW combined-cycle plant with GE 9HA gas turbines, IS200TGNAH1A is deployed in TMR mode to monitor two key generator parameters: steam pressure (via a ±10 V transducer) and generator stator current (via 5 A CTs). It routes the pressure signal to three Mark VIe I/O modules, ensuring the controller receives consistent data even if one I/O module fails. The CT feedback, conditioned by IS200TGNAH1A’s noise filtering, is used to balance load between the plant’s two generators—preventing overcurrent and extending stator winding lifespan.

In a nuclear power plant’s auxiliary steam turbine system, IS200TGNAH1A operates in simplex mode to monitor feedwater pump motor current (via 1 A CTs). Its passive design (no external power) reduces fire risk in safety-related areas, while Level 3 EMC immunity ensures signal stability during reactor startup. The plant’s maintenance team values IS200TGNAH1A’s jumper-based configuration: they can reconfigure inputs for different sensor types (e.g., switching from 4-20 mA to ±5 V) during overhaul without updating software—saving 8 hours of downtime per maintenance cycle.

In a coal-fired plant retrofitting GE D11 steam turbines with Mark VIe, IS200TGNAH1A’s compact size is critical. It fits into the existing control cabinet, routing CT feedback from the generator to a new Mark VIe I/O module. The board’s UL 61010-1 certification ensures compliance with the plant’s electrical safety standards, while its -40 °C to +85 °C operating range withstands the cabinet’s temperature fluctuations during turbine startups and shutdowns.

Related model recommendations

IS200EACFG2A: GE’s system configuration module, which stores Mark VIe I/O module parameters (e.g., CT scaling) used with IS200TGNAH1A. It enables quick I/O replacement, ensuring signal compatibility with IS200TGNAH1A.

IS200IVFBG1A: GE’s voltage/frequency feedback module, which pairs with IS200TGNAH1A to monitor generator voltage (complementing IS200TGNAH1A’s current monitoring). It routes voltage signals to the Mark VIe controller for load balancing.

IS200STAIH2A: GE’s steam turbine analog input module, which receives conditioned signals from IS200TGNAH1A (e.g., steam pressure). It converts analog data to digital for the Mark VIe controller.

IS200TPROH1B: GE’s turbine protection module, which uses CT feedback from IS200TGNAH1A to trigger overcurrent trips. It relies on IS200TGNAH1A’s noise-free signals for accurate protection logic.

IS200EHBQG2A: GE’s Mark VIe backplane module, which powers the I/O modules connected to IS200TGNAH1A. It ensures stable power delivery to maintain signal integrity.

IS200JGNDG1A: GE’s grounding module, which enhances IS200TGNAH1A’s noise reduction by providing low-impedance grounding for CT signals. Critical for plants with long sensor wiring runs (>50 meters).

GE 9T51B0010 CT: A 1 A/5 A current transformer designed for IS200TGNAH1A. It provides generator current feedback optimized for the board’s input specifications.

IS200DTAIH1A: GE’s digital input module, which complements IS200TGNAH1A by monitoring generator status signals (e.g., “CT healthy”)—providing redundant diagnostics for the signal chain.

IS200ERIOH1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200TGNAH1A, power off the Mark VIe I/O module and control cabinet. Verify the environment meets the board’s -40 °C to +85 °C range, and use ESD-safe tools (grounded tweezers, antistatic mat) to avoid damaging components. For wiring: use 18 AWG shielded twisted-pair cables for CT inputs (ground shield at both ends) and 22 AWG cables for analog signals. Configure jumpers (JP1, JP2) before mounting—set JP1 to “voltage” or “current” based on sensor type, and JP2 to “differential” for CT feedback. Mount IS200TGNAH1A using the included screws, ensuring it is aligned with the Mark VIe I/O module’s 37-pin connector.

Maintenance suggestions: Inspect IS200TGNAH1A quarterly for loose wiring or corrosion (common in humid environments). Since it is passive, no power checks are needed—focus on verifying signal continuity between sensors and the Mark VIe I/O module using a multimeter. If CT feedback is noisy, re-tighten shield connections or replace the shielded cable (do not modify jumpers without verifying sensor specs). In TMR systems, test signal fan-out by disconnecting one I/O module and confirming the other two still receive data. If IS200TGNAH1A fails (e.g., broken pins), replace it with a GE-approved unit—generic terminal boards may not support TMR or meet EMC requirements.

Service and guarantee commitment

IS200TGNAH1A comes with a 2-year standard warranty from GE, covering defects in materials (e.g., faulty connectors) and workmanship (e.g., poor soldering). If IS200TGNAH1A fails within this period, GE will repair or replace it free of charge, with expedited shipping from regional warehouses (24-hour delivery to major power hubs) to minimize downtime.

GE offers 24/7 global technical support for IS200TGNAH1A: certified Mark VIe engineers assist with jumper configuration, wiring, and troubleshooting via phone, email, or remote access (using GE’s secure Remote Support Portal). Customers gain access to exclusive resources, including IS200TGNAH1A’s wiring diagrams and TMR signal fan-out guidelines. For mission-critical plants (e.g., nuclear, grid-stabilizing facilities), GE provides extended warranty options (up to 5 years) and annual on-site inspections—ensuring IS200TGNAH1A meets IEC 61010-1 safety standards and operates reliably.