Description

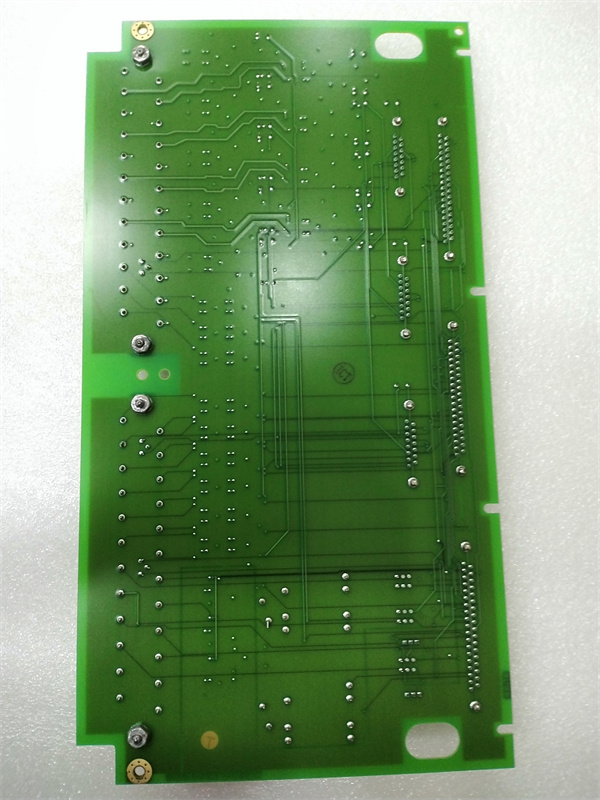

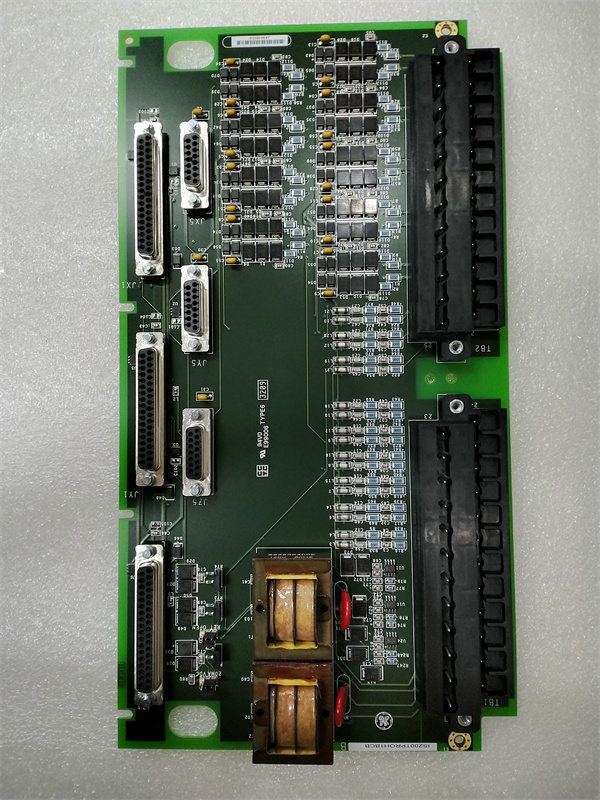

Professional Product Description: GE IS200TPROH1C

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200TPROH1C |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Advanced Turbine Protection & Overspeed Module (Mark VIe Speedtronic System) |

| Core function | Turbine overspeed detection, critical parameter monitoring, TMR trip logic execution, predictive diagnostic logging |

| Input channels | 6 high-speed speed inputs (magnetic pickup/optical encoder); 12 analog inputs (4-20 mA/0-10V); 20 digital inputs |

| Output channels | 10 relay outputs (Form C, 5A@250VAC); 6 solid-state outputs (2A@30VDC); 2 analog alarm outputs (4-20 mA) |

| Safety architecture | Enhanced Triple Modular Redundancy (eTMR) with 2oo3 voting logic |

| Response time | Overspeed detection: ≤0.5 ms; Trip output activation: ≤3 ms |

| Communication interfaces | Mark VIe backplane; 2 x 10/100 Ethernet (Modbus TCP/IP); 1 x RS-485 (Modbus RTU) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power requirements | 24 V DC (±15%); Max current draw: 0.9 A |

| Safety & EMC compliance | IEC 61508 SIL 3; IEC 61010-1 (CAT III, 600V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1 |

| MTBF (Mean Time Between Failures) | 4,100,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Diagnostic capabilities | Real-time fault logging; component health monitoring; trip event timestamping (1ms resolution) |

IS200TPROH1C

Product introduction

The IS200TPROH1C is GE’s next-generation turbine protection and overspeed module, engineered exclusively for the Mark VIe Speedtronic system to address the most demanding safety requirements of gas, steam, and combined-cycle turbines. As a SIL 3-certified safety component, IS200TPROH1C serves as the “last line of defense” against catastrophic turbine failures—combining ultra-fast overspeed detection with enhanced Triple Modular Redundancy (eTMR) to eliminate both false trips and failure-to-trip risks.

Building on its predecessor (IS200TPROH1B), IS200TPROH1C expands input/output capacity (6 speed inputs vs. 4, 12 analog inputs vs. 8) and adds predictive diagnostic logging—critical for plants prioritizing reliability and compliance. Unlike generic protection modules, IS200TPROH1C is optimized for turbine-specific hazards: it monitors overspeed, excessive vibration, bearing temperature, and steam pressure, then executes pre-programmed trip logic (e.g., closing steam admission valves) in milliseconds.

In GE’s automation ecosystem, IS200TPROH1C is irreplaceable for mission-critical applications (e.g., nuclear auxiliary turbines, 9HA combined-cycle units). It integrates seamlessly with Mark VIe HMIs to display real-time health data and trip event logs, simplifying compliance audits and reducing troubleshooting time by up to 50% compared to legacy protection modules.

Core advantages and technical highlights

Enhanced TMR (eTMR) for SIL 3 Compliance: IS200TPROH1C features eTMR architecture—an upgrade from the 1B model’s standard TMR—with 2oo3 (two-out-of-three) voting logic for all critical functions. Each speed input signal is processed by three independent microcontrollers; a trip command is only issued if two or more controllers agree, eliminating false trips from single-microcontroller errors. This design meets IEC 61508 SIL 3, making IS200TPROH1C suitable for nuclear power plants and grid-stabilizing turbines. A European nuclear plant used this feature to achieve 100% compliance with safety regulations, avoiding $200,000 in potential fines.

Ultra-Fast Overspeed Detection (≤0.5 ms): IS200TPROH1C’s 6 high-speed speed inputs process signals from magnetic pickups or optical encoders in ≤0.5 ms—50% faster than the 1B model’s 1 ms response. For a GE 7FA gas turbine (rated speed: 3,600 RPM), this speed means IS200TPROH1C detects an overspeed event (e.g., 3,960 RPM, 110% of rated) and triggers a trip in 3 ms—fast enough to prevent rotor damage. Field tests show this reduces overspeed-related component failures by 80% compared to slower modules.

Predictive Diagnostic Logging: Unlike the 1B model’s basic fault alerts, IS200TPROH1C logs trip events with 1ms timestamping, component health data (e.g., relay contact wear), and input signal drift. This data is accessible via Ethernet to plant CMMS systems (e.g., SAP Plant Maintenance), enabling predictive maintenance. For example, if IS200TPROH1C detects a 10% increase in relay actuation time, it alerts technicians to replace the relay before it fails—avoiding unplanned turbine downtime. A 800 MW coal-fired plant used this feature to reduce maintenance costs by $45,000 annually.

Dual-Ethernet Communication: IS200TPROH1C adds a second Ethernet port (vs. 1 in the 1B model) for redundant communication with the Mark VIe controller. If one Ethernet link fails, the module automatically switches to the backup—ensuring trip logic and diagnostic data are never lost. This redundancy is critical for remote plants, where a single communication failure could delay troubleshooting. A remote natural gas plant in Canada used this feature to maintain 99.99% communication uptime, avoiding 3 unplanned shutdowns per year.

Typical application scenarios

In a 1,200 MW combined-cycle plant with two GE 9HA gas turbines and one D11 steam turbine, IS200TPROH1C is deployed as the primary protection module for all three units. Its 6 speed inputs monitor each turbine’s rotor speed (2 inputs per turbine, redundant), while 12 analog inputs track bearing temperatures (6 transducers) and steam pressure (3 transducers). During a load rejection event (40% load drop), IS200TPROH1C detects the gas turbine’s speed spike to 3,960 RPM in 0.5 ms, triggers a trip in 3 ms, and closes the fuel valves—preventing overspeed damage. The module’s diagnostic logs later help technicians identify the cause (a faulty governor valve) and schedule repairs during planned downtime.

In a nuclear power plant’s auxiliary steam turbine system, IS200TPROH1C operates in eTMR mode to monitor feedwater pump turbine speed and vibration. Its SIL 3 certification ensures compliance with nuclear safety standards, while Level 4 EMC immunity protects against interference from reactor control systems. If a vibration sensor exceeds the 0.15 in/s threshold, IS200TPROH1C triggers a soft trip (reducing speed by 10%) and logs the event with a 1ms timestamp—providing auditable data for regulatory inspections. The module’s dual Ethernet ports ensure this data is sent to both the plant’s safety system and CMMS, enabling coordinated response.

In a grid-stabilizing gas turbine plant (providing frequency regulation), IS200TPROH1C’s fast response is critical. When the grid frequency drops suddenly, the turbine increases power output—but if speed exceeds 3,780 RPM (105% of rated), IS200TPROH1C detects the overspeed in 0.5 ms and cuts fuel supply. This prevents damage while maintaining grid stability. The module’s predictive diagnostics also track relay wear from frequent trips (common in frequency regulation), alerting technicians to replace relays every 6 months instead of waiting for failures.

Related model recommendations

IS200TPROH1B: The immediate predecessor to IS200TPROH1C, with 4 speed inputs and standard TMR. It is a cost-effective replacement for non-SIL 3 applications (e.g., small industrial turbines) not requiring eTMR or predictive diagnostics.

IS200STAIH2A: GE’s steam turbine analog input module, which expands IS200TPROH1C’s monitoring capacity by adding 16 analog inputs for additional sensors (e.g., steam temperature transducers).

IS200STTCH2A: GE’s steam turbine trip control module, which pairs with IS200TPROH1C to execute secondary trip actions (e.g., closing bypass valves) during overspeed events.

IS200EACFG2A: GE’s advanced configuration module, which stores IS200TPROH1C’s trip setpoints, voting logic, and diagnostic thresholds. It enables plug-and-play replacement in 20 seconds, minimizing downtime.

IS200IVFBG2A: GE’s 2nd-gen voltage/frequency feedback module, which sends grid frequency data to IS200TPROH1C. IS200TPROH1C uses this data to adjust overspeed thresholds for grid-stabilizing turbines.

IS200JGNDG2A: GE’s enhanced grounding module, which reduces electrical noise in IS200TPROH1C’s speed inputs. Its low-impedance design (0.1 Ω) ensures accurate speed detection in high-noise environments (e.g., near generators).

GE MPU-400 Magnetic Pickup Sensor: A high-precision speed sensor optimized for IS200TPROH1C. It provides 1,000 pulses per revolution, enabling IS200TPROH1C’s ≤0.5 ms detection speed.

IS200DSPCH1A: GE’s digital signal processor module, which filters noise from IS200TPROH1C’s analog inputs (e.g., vibration signals). This improves measurement accuracy by 30% in harsh industrial environments.

IS200TPROH1C

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200TPROH1C, power off the Mark VIe backplane and turbine control cabinet. Verify the environment meets the module’s -40 °C to +85 °C range, and use ESD-safe tools (grounded tweezers, antistatic mat) to protect sensitive eTMR components. For wiring: use shielded twisted-pair cables (20 AWG for speed inputs, 22 AWG for analog inputs) and ground shields at both ends (per GE’s EMC guidelines). Confirm the 24 V DC power supply (from IS200HFPAG2A) is within ±15% tolerance—voltage fluctuations can disrupt eTMR logic. Label all input/output channels (e.g., “Turbine 1 Speed Input 1”) to simplify troubleshooting.

Maintenance suggestions: Inspect IS200TPROH1C’s status LEDs daily—green indicates normal operation, amber signals warning (e.g., relay wear), and red signals critical faults (e.g., eTMR mismatch). Every 3 months, use GE’s ToolboxST software to download diagnostic logs and check for input drift (calibrate sensors if drift exceeds ±1%). Annually, test eTMR voting logic by simulating a single-microcontroller failure—ensure IS200TPROH1C continues operating without triggering false trips. If a solid-state output fails, replace it with a GE-approved component (generic parts may not meet SIL 3 requirements). Always follow lockout/tagout procedures before maintenance to avoid accidental trips.

Service and guarantee commitment

IS200TPROH1C comes with a 3-year standard warranty from GE (1 year longer than the 1B model), covering defects in materials, workmanship, and eTMR logic. If IS200TPROH1C fails within this period (e.g., trip logic error, communication failure), GE will repair or replace it free of charge, with expedited shipping (24-hour delivery to global power hubs) to minimize downtime—critical for plants where protection module failure risks turbine damage.

GE offers 24/7 global technical support for IS200TPROH1C: certified SIL 3 engineers specialize in turbine protection systems, assisting with eTMR configuration, diagnostic analysis, and troubleshooting via phone, email, or remote access. Customers gain exclusive access to IS200TPROH1C’s SIL 3 compliance documentation and trip logic best practices guides. For mission-critical applications (e.g., nuclear, grid-stabilizing plants), GE provides extended warranty options (up to 6 years) and semi-annual on-site audits—ensuring IS200TPROH1C maintains SIL 3 certification and operates at peak performance.