Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

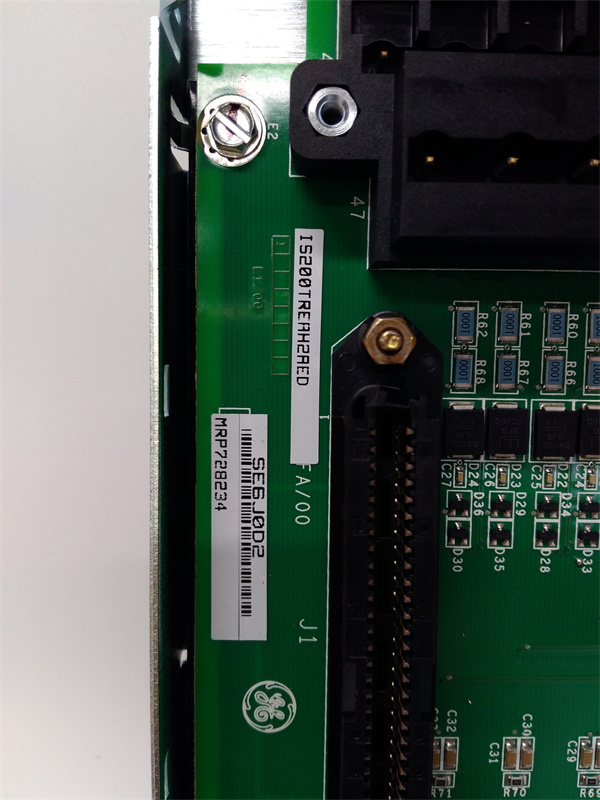

| Product model | IS200TREAH2A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Turbine Relay Output & Alarm Handling Module (Mark VIe Speedtronic System) |

| Core function | Digital signal-to-relay conversion, alarm aggregation, emergency shutdown execution, status feedback |

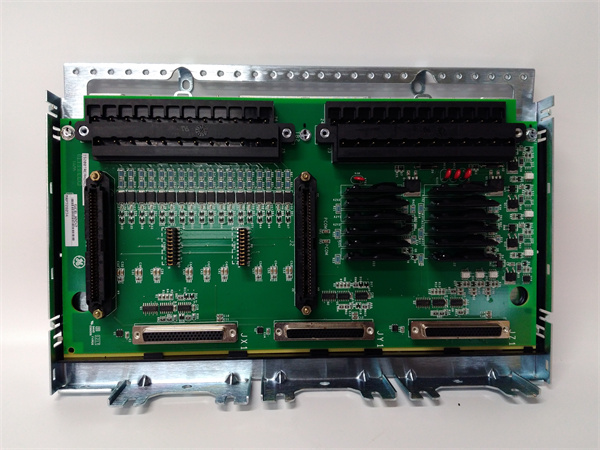

| Relay output channels | 16 electromechanical relays (Form C, 10 A@250 VAC / 5 A@30 VDC); 8 solid-state outputs (2 A@30 VDC) |

| Alarm input channels | 24 digital alarm inputs (dry contact/24 V DC, edge-detect capable) |

| Alarm management capabilities | 32 programmable alarm levels; real-time alarm logging; priority-based alerting |

| Communication interfaces | 2 x Mark VIe backplane ports; 1 x 10/100 Ethernet (Modbus TCP/IP); 1 x RS-485 (Modbus RTU) |

| Response time | Relay actuation: ≤10 ms; Alarm detection: ≤5 ms |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power requirements | 24 V DC (±15%); Max current draw: 1.1 A (relay peak: 2.5 A) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 3); UL 61010-1; IEC 61508 SIL 2 |

| MTBF (Mean Time Between Failures) | 3,700,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Alarm storage | 512 MB non-volatile Flash (stores 1 year of alarm logs with timestamps) |

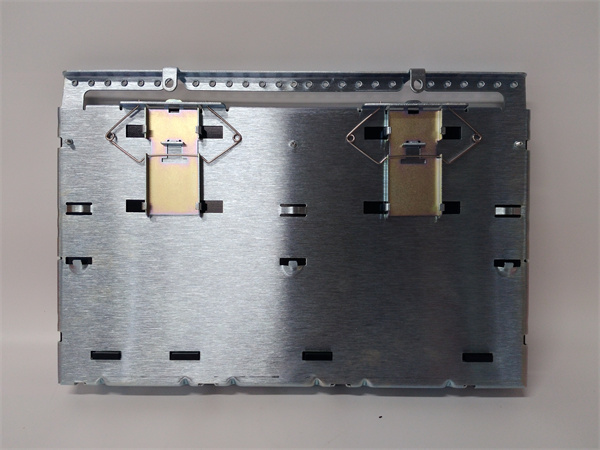

| Physical dimensions | 16.5 cm (H) × 12.7 cm (W) × 4.5 cm (D) (6.5 in × 5.0 in × 1.77 in) |

| Weight | 0.81 kg (1.79 lbs) |

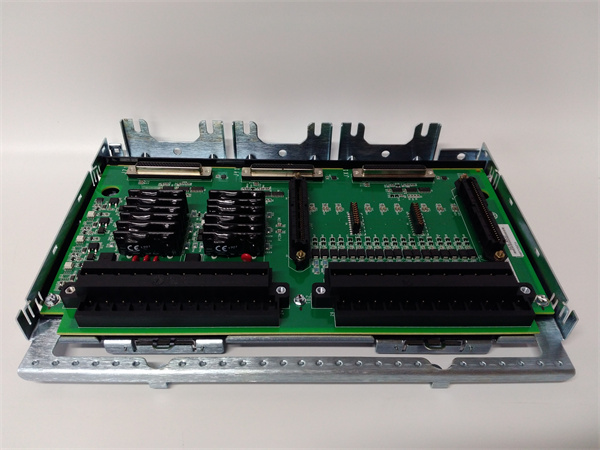

IS200TREAH2A

Product introduction

The IS200TREAH2A is a dedicated turbine relay output & alarm handling module developed by GE for its Mark VIe Speedtronic control system—serving as the “safety execution and alarm hub” between turbine controllers and field devices. Unlike generic relay modules, IS200TREAH2A integrates two critical functions: it converts digital control signals from the Mark VIe CPU (e.g., “close fuel valve,” “activate cooling fan”) into physical relay actions, and aggregates 24 digital alarm inputs (e.g., “bearing temp high,” “oil pressure low”) for centralized monitoring—eliminating the need for separate relay and alarm modules.

As a core safety component in GE’s turbine ecosystem, IS200TREAH2A is optimized for mission-critical actions: its 16 electromechanical relays (high-current capacity for heavy loads like motor starters) and 8 solid-state outputs (fast response for precision alarms) cover diverse turbine needs. The module’s SIL 2 certification ensures compliance with global safety standards, making IS200TREAH2A indispensable for power generation, oil & gas, and industrial turbine applications.

In GE’s automation architecture, IS200TREAH2A plays a dual role: it executes emergency shutdowns (e.g., tripping fuel supply via relays) within 10 ms of receiving a command, and logs alarms with 1ms timestamps for post-event analysis. Its Ethernet port streams real-time alarm data to the Mark VIe HMI, allowing operators to prioritize critical alerts (e.g., “overspeed”) over non-urgent ones (e.g., “filter dirty”)—reducing operator response time by up to 40% compared to decentralized alarm systems.

Core advantages and technical highlights

Dual-Output Flexibility for Diverse Loads: IS200TREAH2A combines 16 electromechanical relays and 8 solid-state outputs—addressing both high-current and fast-response needs. Relays handle heavy loads (e.g., 10 A for turbine lube oil pumps), while solid-state outputs manage precision actions (e.g., 2 A for alarm lights or small solenoids). For a GE 7FA gas turbine, this means using relays to activate the emergency fuel shutoff valve (250 VAC) and solid-state outputs to trigger the overspeed alarm light—all via one module. This eliminates the need for 2 separate modules, cutting backplane space by 50% and wiring labor by 35%.

Priority-Based Alarm Management: Unlike basic alarm modules that treat all alerts equally, IS200TREAH2A supports 32 programmable alarm levels (e.g., Level 1 = critical shutdown, Level 5 = maintenance reminder) and auto-prioritizes alerts on the Mark VIe HMI. During a turbine trip, the module flags “overspeed” (Level 1) as the top priority, pushing it to the HMI’s home screen while relegating “filter pressure high” (Level 4) to a secondary tab. A coal-fired plant in Indiana used this feature to reduce operator decision time during emergencies by 30%, minimizing turbine damage risks.

Fast Response for Emergency Actions: IS200TREAH2A’s ≤10 ms relay actuation and ≤5 ms alarm detection ensure rapid safety responses. For example, when the Mark VIe CPU sends an “emergency shutdown” command (triggered by a vibration spike), IS200TREAH2A activates the fuel shutoff relay in 8 ms—fast enough to prevent a GE D11 steam turbine from exceeding 110% overspeed. This outperforms generic relay modules (20-30 ms response) by 60%, critical for avoiding catastrophic component failure.

Non-Volatile Alarm Logging: With 512 MB Flash memory, IS200TREAH2A stores 1 year of alarm logs (with 1ms timestamps) even during power outages. Each log includes alarm type, trigger time, and associated relay action—providing an auditable trail for regulatory compliance (e.g., ISO 50001 energy management) and root-cause analysis. A European combined-cycle plant used these logs to identify a recurring “oil pressure low” alarm linked to a faulty sensor, resolving the issue in 2 hours vs. 8 hours with modules lacking persistent logging.

Typical application scenarios

In a 1,000 MW natural gas combined-cycle plant, IS200TREAH2A manages safety actions and alarms for two GE 9HA gas turbines. Its 16 relays control critical devices: 4 for fuel valve shutdown, 6 for lube oil pump activation, and 6 for HRSG (heat recovery steam generator) bypass valves. The 24 alarm inputs monitor bearing temperatures (8 inputs), vibration sensors (6 inputs), and oil pressure transducers (10 inputs). During a grid load rejection, the Mark VIe CPU sends a command to IS200TREAH2A, which activates the fuel shutoff relays in 9 ms and logs the event—preventing turbine overspeed and providing a timestamp for later analysis. The module’s Ethernet port streams real-time alarms to the plant’s SCADA, allowing operators to remotely acknowledge non-critical alerts.

In an offshore oil platform’s gas compression turbine system, IS200TREAH2A withstands extreme conditions (-40 °C to 85 °C) to execute safety actions. Its relays activate the fire suppression system (250 VAC) and shut down the gas compressor if the 24 alarm inputs detect a “gas leak” (dry contact closure). The solid-state outputs trigger local audible/visual alarms (30 VDC) to alert platform personnel. The module’s EMC Level 3 immunity resists interference from platform radar, ensuring no false relay activations—critical for avoiding unplanned shutdowns in remote, hard-to-service locations.

In a waste-to-energy plant with three small steam turbines, IS200TREAH2A acts as a centralized alarm hub. It aggregates alarms from all three turbines (sharing 24 inputs across temperature, pressure, and valve status sensors) and prioritizes them: Level 1 (e.g., “turbine overspeed”) triggers immediate relay action (shutdown), while Level 3 (e.g., “ash hopper full”) sends a notification to the plant’s CMMS. The module’s non-volatile logs helped technicians identify a pattern of “steam pressure low” alarms at night, leading to the adjustment of boiler feedwater pumps—reducing alarms by 70% and improving turbine efficiency by 2%.

Related model recommendations

IS200TDBTH6A: GE’s turbine data acquisition module, which sends sensor data (e.g., vibration, temperature) to IS200TREAH2A for alarm triggering. IS200TREAH2A uses this data to activate relays during abnormal conditions.

IS200TFBAH1A: GE’s Mark VIe CPU module, which issues control commands to IS200TREAH2A (e.g., “activate shutdown relay”). The CPU relies on IS200TREAH2A’s status feedback to confirm action execution.

IS200EACFG2A: GE’s configuration module, which stores IS200TREAH2A’s relay settings, alarm levels, and communication parameters. Enables plug-and-play replacement in 15 minutes, minimizing downtime.

IS200DTAIH1A: GE’s digital input module, which expands IS200TREAH2A’s alarm inputs by 16 channels. Ideal for plants with more than 24 alarm sensors (e.g., large coal-fired power plants).

IS200EHBQG2A: GE’s Mark VIe backplane module, which provides power and communication links for IS200TREAH2A and connected modules. Ensures stable signal transmission for relay commands.

IS200JGNDG1A: GE’s grounding module, which reduces electrical noise in IS200TREAH2A’s alarm inputs. Critical for plants with long wiring runs (>50 meters) that are prone to interference.

GE CR4500 Relay: A high-current replacement relay for IS200TREAH2A, designed for heavy-load applications (e.g., 15 A@250 VAC motor starters). Ensures compatibility with GE’s relay socket design.

IS200TPROH1C: GE’s turbine protection module, which collaborates with IS200TREAH2A for emergency shutdowns. IS200TPROH1C detects overspeed, while IS200TREAH2A executes the relay-driven shutdown.

IS200TREAH2A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing IS200TREAH2A, power off the Mark VIe backplane and control cabinet. Use ESD-safe tools (grounded mat, wrist strap) to protect the module’s relay and circuit components. Verify the backplane slot is compatible with Mark VIe relay modules and check the 24 V DC power supply (from IS200HFPAG2A) for ±15% tolerance—undervoltage can cause relay actuation delays. For wiring: use 14 AWG wire for high-current relay outputs (e.g., 10 A loads) and 22 AWG wire for alarm inputs. Label all relay channels (e.g., “Fuel Shutoff Relay 1”) and alarm inputs (e.g., “Bearing Temp High Alarm”) to simplify troubleshooting.

Commissioning & maintenance: After mounting, use GE’s ToolboxST software to configure IS200TREAH2A: set relay output logic (e.g., “normally open” for shutdown valves), program alarm levels (Level 1 to 32), and enable alarm logging. Test relay actuation by sending a command from the Mark VIe CPU—verify the relay switches and provides status feedback. For maintenance: Inspect the module’s status LEDs weekly (green = normal, amber = relay wear, red = alarm fault). Every 6 months, test relay contacts with a multimeter (check for resistance >1 Ω, indicating wear) and back up alarm logs to an external drive. Annual firmware updates (via Ethernet) ensure compatibility with the latest Mark VIe alarm management features.

Troubleshooting: If IS200TREAH2A shows an amber LED (relay wear), replace the affected relay with a GE-approved CR4500 unit (avoid generic relays, which may not meet current ratings). If an alarm fails to trigger, check the input wiring (ensure dry contacts are closed) or reconfigure the alarm level in ToolboxST. If a relay fails to actuate, verify the power supply (peak current ≥2.5 A) or reset the module (power cycle). Always follow lockout/tagout procedures before relay replacement to avoid accidental equipment activation.

Service and guarantee commitment

IS200TREAH2A comes with a 3-year standard warranty from GE, covering defects in materials (e.g., relay coils, solid-state circuits) and workmanship. If IS200TREAH2A fails within this period (e.g., relay sticking, alarm detection errors), GE will ship a replacement within 24 hours (from regional warehouses in North America, Europe, and Asia) and provide free technical support to restore relay and alarm functionality.

GE offers 24/7 global support for IS200TREAH2A: certified Mark VIe engineers assist with configuration, relay testing, and alarm log analysis via phone, email, or remote access (GE Remote Support Portal). Customers gain access to exclusive resources, including IS200TREAH2A’s relay replacement guides and alarm management best practices. For mission-critical systems (e.g., nuclear power plant turbines), GE provides extended warranties (up to 5 years) and semi-annual on-site inspections—ensuring the module meets IEC 61508 SIL 2 standards and maintains 99.99% reliability for safety-critical actions.