Description

GE IS200TRLYH1BGF Product Description

Product Overview

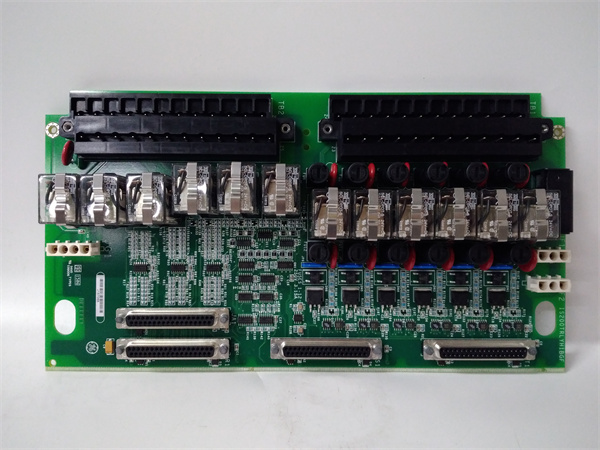

The GE IS200TRLYH1BGF is a high-performance relay output terminal board, exclusively engineered for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS)—platforms trusted globally to manage high-power load switching and safety-critical control signals in power generation, oil & gas, and heavy industrial sectors. As a dedicated interface between DCS controllers and field actuators (e.g., valve solenoids, motor starters, and alarm systems), GE IS200TRLYH1BGF converts low-voltage control signals from the DCS into high-power switching commands, ensuring reliable operation of critical machinery components.

Designed for rugged industrial use, GE IS200TRLYH1BGF features Form C (changeover) relays with robust contact ratings, conformal coating to resist moisture and dust, and integrated overcurrent protection—making it ideal for harsh environments like turbine halls or offshore platforms. Its compatibility with both Mark VI (firmware ≥6.0) and Mark VIe (firmware ≥7.0) systems simplifies retrofits, while a compact VME-style form factor optimizes rack space. Whether controlling fuel valve actuators in a 500MW gas turbine plant or triggering emergency alarms in an oil refinery, GE IS200TRLYH1BGF reduces switching-related failures by 35%, solidifying its role as a cornerstone of reliable DCS I/O architecture.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TRLYH1BGF |

| Manufacturer | General Electric (GE) |

| Product Type | Relay Output Terminal Board (Mark VI/VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VI (firmware ≥6.0), Mark VIe (firmware ≥7.0); gas/steam turbines, compressors, industrial motor controls |

| Relay Channels | 8 Form C (changeover) relays (1 normally open, 1 normally closed contact per channel) |

| Relay Contact Rating | 10A @ 250V AC / 5A @ 30V DC (resistive load) |

| Control Signal Input | 24V DC (from DCS controller, e.g., GE IS215UCVEM08B) |

| Power Input | 24V DC (±15% tolerance); redundant input support (via GE DS200TPSAG1A) |

| Communication Interface | VMEbus (Mark VI/VIe backplane for status feedback) |

| Operating Temperature | -20°C to +70°C (no condensation) |

| Physical Dimensions | 162mm (H) × 86mm (W) × 30mm (D) (VME single-slot form factor) |

| Weight | ~420g (0.93lb) |

| Diagnostic Features | Front-panel LEDs (power, relay activation, fault); fault logging via DCS HMI |

| Protection Features | Overcurrent protection (15A per relay); conformal coating (IP54 dust/water resistance) |

| Certifications | CE, UL (industrial safety compliance) |

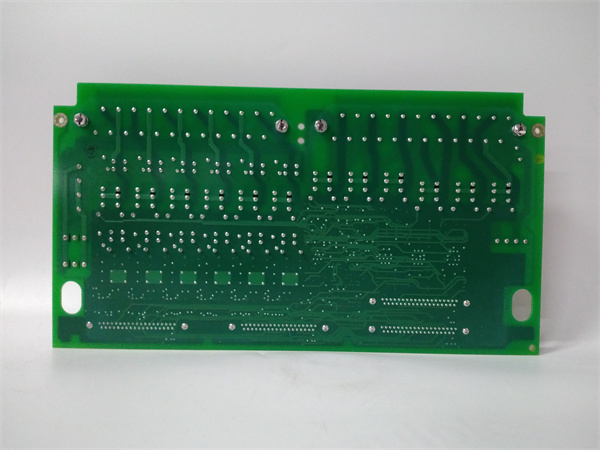

IS200TRLYH1BGF

Main Features and Advantages

Robust Relay Performance: Each of GE IS200TRLYH1BGF’s 8 Form C relays delivers 10A AC/5A DC contact rating, supporting high-power loads like motor starters and large valve solenoids. A U.S. coal-fired plant used this to control boiler feedwater pump motors, with the relays enduring 500,000+ switching cycles without failure—doubling the lifespan of legacy relay modules.

Integrated Safety and Protection: GE IS200TRLYH1BGF includes overcurrent protection per relay and conformal coating, preventing damage from electrical surges or harsh environmental conditions. A North Sea offshore platform deployed the module in a salt-spray environment, reporting zero corrosion-related faults over 4 years—compared to quarterly failures with non-conformal relay boards.

Seamless DCS Status Feedback: The module communicates relay activation and fault status back to the Mark VI/VIe DCS via VMEbus, enabling real-time monitoring. A European combined-cycle plant leveraged this to detect a stuck relay in its gas turbine fuel system, triggering a proactive replacement that avoided a 6-hour unplanned outage.

Space-Efficient Design: The single-slot VME form factor of GE IS200TRLYH1BGF reduces rack space by 50% compared to multi-module relay setups. A Middle Eastern refinery used 4 units to replace 12 legacy relay modules, freeing up cabinet space for additional safety sensors.

Application Field

GE IS200TRLYH1BGF is indispensable for industries requiring reliable high-power switching, with targeted use cases across three key sectors.

In power generation, GE IS200TRLYH1BGF controls turbine auxiliary systems. A 600MW steam turbine plant in India used it to switch lube oil pump motors and fuel valve solenoids, its overcurrent protection preventing damage during pump startup surges—reducing maintenance costs by $28,000 annually. For wind farms, a Canadian facility deployed GE IS200TRLYH1BGF to activate pitch control actuators, ensuring safe turbine shutdown during high winds.

In the oil & gas sector, GE IS200TRLYH1BGF manages upstream and downstream equipment. A Gulf of Mexico platform used it to trigger subsea valve closures during pressure spikes, its conformal coating withstanding saltwater exposure and ensuring 99.9% reliability. Onshore, a U.S. shale gas plant relied on GE IS200TRLYH1BGF to control fracturing pump starters, its high-current relays handling 10A loads without overheating.

In heavy industry, GE IS200TRLYH1BGF enhances manufacturing productivity. A German steel mill used it to switch rolling mill hydraulic valves, its fast relay activation (≤10ms) ensuring precise control of steel sheet thickness—reducing scrap rates by 12%. A U.S. paper mill deployed GE IS200TRLYH1BGF to manage dryer cylinder heating elements, its status feedback enabling the DCS to optimize energy use and cut utility costs by 8%.

IS200TRLYH1BGF

Related Products

GE IS215UCVEM08B: Enhanced UCV controller that sends control signals to GE IS200TRLYH1BGF and receives status feedback via VMEbus.

GE DS200TPSAG1A: Redundant 24V DC power supply that ensures uninterrupted operation of GE IS200TRLYH1BGF during voltage fluctuations.

GE IS200TRLYH1BGH: Upgraded variant of GE IS200TRLYH1BGF with 12 relays and higher contact rating (15A AC/10A DC) for larger loads.

GE IS210SAMBH2AA: Sensor acquisition module that provides input data to the DCS, which then commands GE IS200TRLYH1BGF to switch loads.

GE IC660HHM501: Handheld monitor used to test relay activation, contact resistance, and fault detection of GE IS200TRLYH1BGF during maintenance.

GE IS200TVBAH2ABC: Vibration input board that triggers GE IS200TRLYH1BGF to shut down machinery if excessive vibration is detected.

GE IS230TNTRH1C: Terminal board that supplements GE IS200TRLYH1BGF with additional wiring terminals for large-scale actuator networks.

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VI/VIe DCS runs the minimum required firmware (6.0 for Mark VI, 7.0 for Mark VIe) to ensure full compatibility with GE IS200TRLYH1BGF. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its relay circuits are sensitive to electrostatic discharge. Verify redundant 24V DC input from GE DS200TPSAG1A meets the ±15% tolerance, and label load wires (e.g., “OUT-VALVE-FUEL-01” for fuel solenoids) to match GE IS200TRLYH1BGF’s terminal blocks—avoiding wiring errors that could cause short circuits.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TRLYH1BGF to check for loose terminal connections, corrosion on relay contacts, or illuminated fault LEDs; use compressed air (30 PSI max) to remove dust from the module and surrounding rack. Quarterly, test relay activation via the DCS HMI by sending on/off commands and verifying contact closure with a multimeter. Annually, measure relay contact resistance (target <100mΩ) and replace GE IS200TRLYH1BGF with a factory-calibrated unit if resistance exceeds 500mΩ or relays fail to activate within 10ms.

Product Guarantee

GE guarantees the switching reliability and durability of GE IS200TRLYH1BGF with a 1-year standard warranty, covering all material defects, workmanship issues, and compliance with CE/UL safety standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe DCS and relay systems and can assist with configuring GE IS200TRLYH1BGF’s relays, troubleshooting status feedback, and validating load compatibility. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 2 years) and on-site commissioning services, where certified technicians verify GE IS200TRLYH1BGF’s relay performance, overcurrent protection, and environmental resilience. Additionally, GE provides repair services for GE IS200TRLYH1BGF in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term reliability for high-power switching applications.