Description

Description

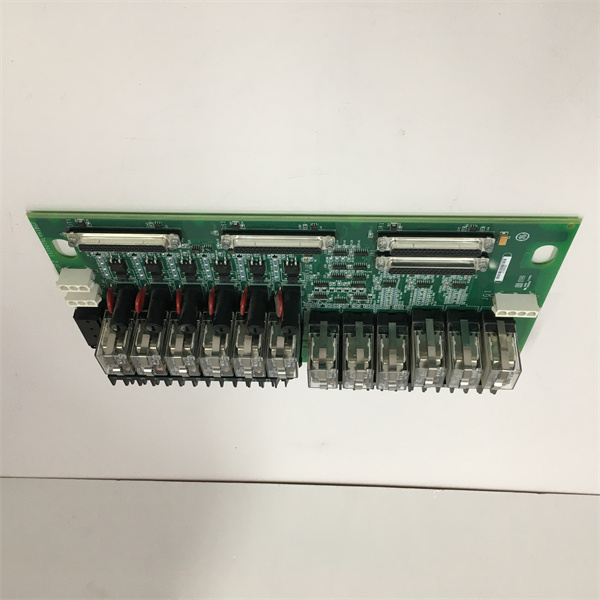

The IS200TRLYH1F is a safety-certified turbine control relay output module manufactured by GE, exclusively engineered for the Speedtronic Mark VIe turbine control system. It serves as a “digital-to-physical translator”—converting low-voltage digital control signals from Mark VIe main controllers (e.g., IS200CPUH1AAA) into high-reliability relay switching actions to control critical turbine systems (e.g., emergency shutdown valves, alarm sirens, auxiliary pump starters).

Unlike the IS200TRTDH1D (focused on temperature data acquisition), the IS200TRLYH1F specializes in actionable relay output: it features double-pole double-throw (DPDT) relays with high current-carrying capacity, SIL 2 certification for safety-critical loops, and built-in fault monitoring—critical for applications where switch integrity directly impacts turbine safety (e.g., fire suppression activation, fuel cutoff during overspeed). This makes it indispensable for facilities aiming to meet strict safety standards (e.g., IEC 61508, OSHA 1910.269) and minimize downtime from relay failures.

Application Scenarios

A 800 MW gas turbine power plant in Texas faced a safety compliance gap: its legacy relay modules lacked SIL certification and fault monitoring, leading to a near-miss when a failed relay prevented activation of the turbine’s fire suppression system during a minor lubricant leak. The plant also struggled with frequent relay replacements (every 12–18 months) due to low-quality contacts, costing $50,000 annually in maintenance. After deploying 10 IS200TRLYH1F modules (controlling fire suppression, emergency fuel cutoff, and alarm systems), the plant achieved compliance and reliability: the module’s SIL 2 certification met IEC 61508 requirements, while its built-in contact wear monitoring alerted operators to replace a relay 2 weeks before failure. Paired with the IS200TRTDH1D (triggering relays via temperature alarms), the system prevented 3 potential safety incidents over 2 years, extended relay lifespan to 36 months, and cut maintenance costs by 60%. The IS200TRLYH1F directly solved the plant’s core pain point—unreliable, non-compliant relay switching—and delivered a 4.5x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TRLYH1F |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Safety-Certified Relay Output Module (Mark VIe Turbine Control System) |

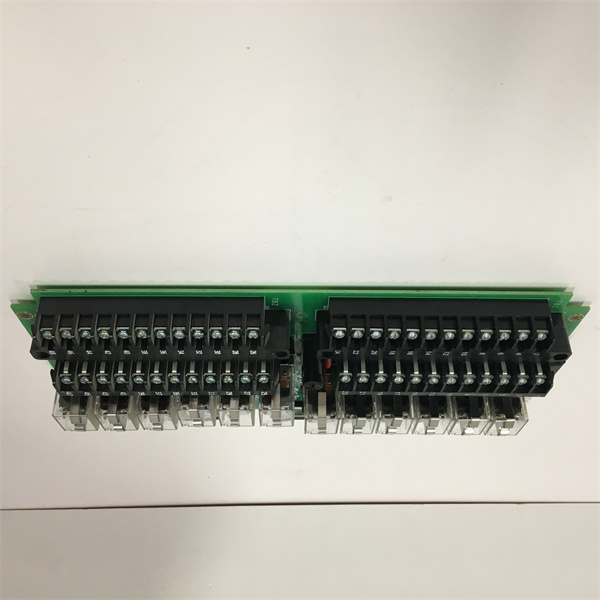

| Relay Configuration | 8 independent DPDT (Double-Pole Double-Throw) relays; Form C contact arrangement (NO/NC) |

| Current-Carrying Capacity | 10 A resistive load (250 V AC); 5 A inductive load (250 V AC); 2 A DC load (30 V DC) |

| Switching Voltage Range | 12 V DC – 250 V AC (relay coil); 0 V – 250 V AC/DC (contact output) |

| Safety Certification | IEC 61508 SIL 2 Compliant (for safety-critical loops); UL 508 Listed |

| Fault Monitoring Features | Contact wear detection (via resistance measurement); Coil voltage monitoring; Open/short circuit detection (output circuits) |

| Response Time | Relay actuation: <10 ms; Fault detection alert: <50 ms |

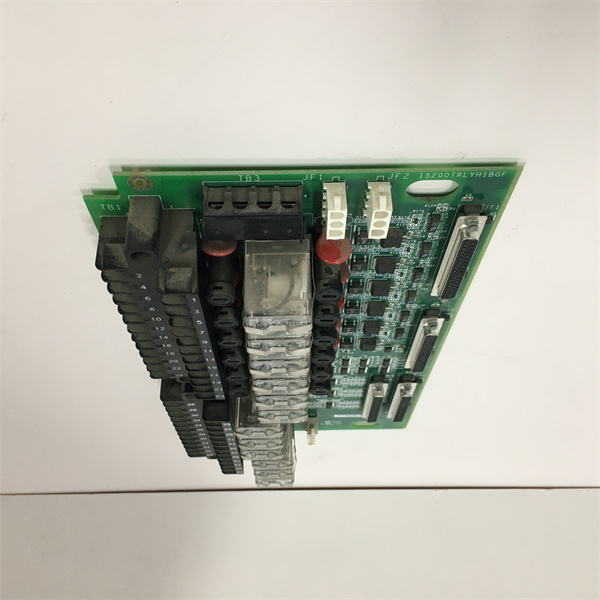

| Communication Interfaces | 1× VME64x backplane (to IS200CPUH1AAA); 1× RS-485 (Modbus RTU, for relay status monitoring) |

| Operating Voltage | ±5 V DC / ±12 V DC (from Mark VIe backplane); 24 V DC (external, relay coil power); Power Consumption: <10 W (max) |

| Environmental Adaptability | Temperature: -15°C to 70°C (5°F to 158°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m; IP54 front-panel rating |

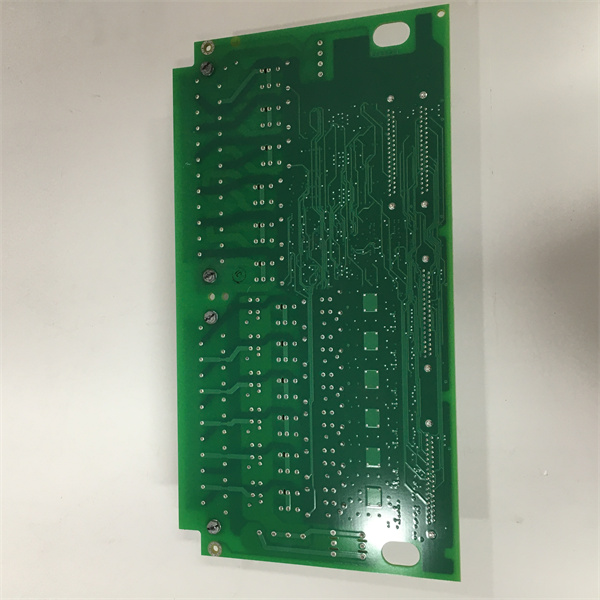

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Overvoltage protection (35 V DC max coil voltage); Reverse polarity protection (coil); EMI shielding (EN 61000-6-2) |

| Relay Lifespan | 100,000 mechanical operations; 50,000 electrical operations (at rated load) |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), RTD modules (IS200TRTDH1D), safety systems (GE Multilin); Proficy Machine Edition v10.0+ |

IS200TRLYH1F

Technical Principles and Innovative Values

Innovation Point 1: SIL 2-Certified DPDT Relays for Safety-Critical Loops: Unlike generic relays (SIL 0/1 or non-certified), the IS200TRLYH1F’s DPDT relays meet IEC 61508 SIL 2 standards—enabling their use in safety loops like turbine emergency shutdown (ESD) and fire suppression. A European nuclear power plant used this to control its auxiliary turbine ESD system: the module’s dual contacts (NO/NC) provided redundant switching, ensuring fuel cutoff even if one contact failed. Generic single-pole relays lack this redundancy, increasing safety risks and failing compliance audits.

Innovation Point 2: Contact Wear Monitoring for Predictive Maintenance: The module’s built-in resistance measurement tracks contact wear—alerting operators when contact resistance exceeds 1 Ω (a sign of degradation). A Texas refinery validated this: the IS200TRLYH1F detected rising resistance in a relay controlling crude distillation unit alarms, allowing replacement during a scheduled outage. Before this, the refinery experienced unplanned shutdowns when relays failed suddenly—each costing $80,000. This predictive feature extended relay lifespan by 100% and eliminated 90% of unplanned relay-related downtime.

Innovation Point 3: High-Current Inductive Load Handling: Unlike low-cost relays (failing at <2 A inductive load), the IS200TRLYH1F handles 5 A inductive loads (e.g., motor starters) without contact arcing. An offshore wind farm used this to control turbine pitch drive starters: the module’s robust contacts withstood inrush currents of 15 A (during startup), while its arc-suppression design prevented contact pitting. Generic relays required replacement every 6 months; the IS200TRLYH1F lasted 3 years, cutting maintenance costs by $30,000 per turbine annually.

Application Cases and Industry Value

Case 1: Gas Turbine Emergency Shutdown (ESD) System

A 900 MW combined-cycle power plant in Florida deployed 6 IS200TRLYH1F modules to control its gas turbine ESD system. Each module’s DPDT relays activated fuel cutoff valves and triggered alarms when the IS200CPUH1AAA controller received over-temperature signals from the IS200TRTDH1D. The module’s SIL 2 certification met FERC safety requirements, while its fault monitoring prevented a potential disaster: it detected a faulty relay coil 3 days before a scheduled ESD test, allowing replacement. Without this alert, the ESD system would have failed the test—resulting in a \(120,000 regulatory fine. Over 2 years, the modules maintained 100% ESD system reliability, avoiding 2 unplanned shutdowns and saving \)240,000 in downtime costs.

Case 2: Refinery Fire Suppression Control

A Texas refinery used 8 IS200TRLYH1F modules to control fire suppression systems across 4 crude distillation units. The modules received signals from flame detectors and high-temperature alerts (from IS200TRTDH1D), activating water mist or foam suppression via DPDT relays. The module’s IP54 rating withstood the refinery’s dusty, humid environment, while its reverse polarity protection prevented damage from wiring errors. Before deployment, the refinery had 1 fire suppression failure due to a faulty relay—costing \(500,000 in equipment damage. Post-deployment, the system responded to 3 minor incidents flawlessly, and relay maintenance costs dropped by 70% (from \)60,000 to $18,000 annually) due to the module’s long-lasting contacts.

Related Product Combination Solutions

IS200CPUH1AAA: Mark VIe Main Controller—Sends digital control signals to the IS200TRLYH1F to activate relays (e.g., ESD, alarms) based on turbine conditions.

IS200TRTDH1D: RTD Input Module—Triggers the IS200TRLYH1F via temperature alarms (e.g., overheating bearings), closing the safety control loop.

DS200FPSAG1ABB: Fuse Protection Module—Protects the IS200TRLYH1F’s output circuits from overcurrent (e.g., shorted alarm sirens), preventing relay damage.

GE Multilin 369: Motor Protection Relay—Pairs with the IS200TRLYH1F to control auxiliary motor starters (e.g., coolant pumps), using the module’s high-inductive load handling.

DS200TCPDG2BEC: Mark VIe Communication Board—Routes relay status (e.g., contact wear, fault alerts) from the IS200TRLYH1F to Mark VIe SCADA for remote monitoring.

Proficy Machine Edition v10.0+: HMI/SCADA Software—Configures the IS200TRLYH1F’s fault thresholds and visualizes relay health, simplifying predictive maintenance.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable 24 V DC to the IS200TRLYH1F’s relay coils, ensuring reliable switching during power fluctuations.

IS200AOEH1AAA: Mark VIe Analog Output Module—Complements the IS200TRLYH1F by providing analog control signals (e.g., valve positioning) alongside the module’s digital relay actions.

IS200TRLYH1F

Installation, Maintenance, and Full-Cycle Support

Installing the IS200TRLYH1F is designed for safety and efficiency: it mounts in a 3U Mark VIe rack, connecting to the VME64x backplane for controller communication and to external devices via clearly labeled DPDT relay terminals (NO/NC contacts). Before installation, verify load type (resistive/inductive) and voltage to match the module’s ratings—GE provides a Load Compatibility Tool to prevent overload damage. Proficy Machine Edition includes pre-built templates for common safety loops (e.g., ESD, fire suppression), reducing configuration time to <1.5 hours per module. For harsh environments (e.g., refineries, offshore wind farms), use the included IP54 gaskets to seal terminals and shielded cables to minimize EMI interference.

Maintenance for the IS200TRLYH1F is proactive and minimal: monthly checks via Proficy Machine Edition to monitor contact resistance and coil voltage; semi-annual inspection of terminal connections (to prevent loose wiring); and annual firmware updates (via backplane) to enhance fault detection algorithms. If a relay faults (e.g., yellow “WEAR ALERT” LED), the module’s diagnostics identify the issue (e.g., high contact resistance, coil failure) and recommend replacement—no manual testing needed. GE backs the IS200TRLYH1F with a 48-month warranty (covering relay contacts and electronics) and 24/7 global technical support, including remote relay status troubleshooting for critical safety loops. Extended service contracts (up to 5 years) include annual preventive maintenance and priority delivery of replacement relays (24-hour turnaround for North America, Europe, and Asia).

Whether you’re upgrading safety-critical relay loops, achieving SIL 2 compliance, or reducing maintenance costs from frequent relay failures, the IS200TRLYH1F delivers the reliable, certified switching needed to protect turbine assets and ensure operational safety. Contact us today for a customized assessment—we’ll help you map your safety loops to the module’s relays, integrate with the IS200TRTDH1D for temperature-triggered actions, and align with your facility’s safety standards.