Description

GE IS200TRLYH1FAA Product Description

Product Overview

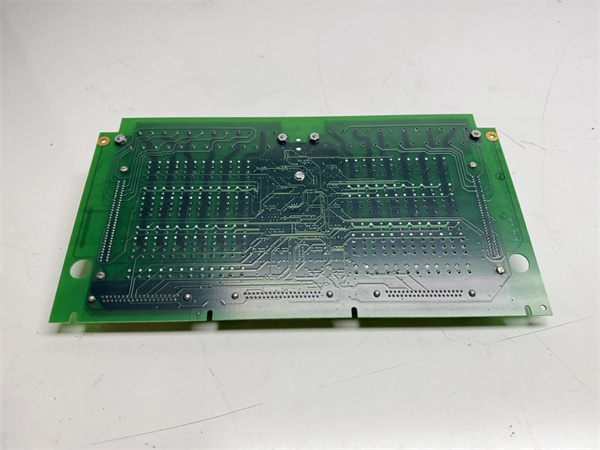

The GE IS200TRLYH1FAA is a high-performance relay output module designed for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS), serving as a critical link between turbine control logic and field actuators in industrial automation. As a core component in turbine control loops, GE IS200TRLYH1FAA converts low-voltage digital control signals from the Mark VI/VIe controller into high-power relay outputs, enabling precise operation of critical equipment such as fuel valves, emergency stop solenoids, and lube oil pumps.

Engineered for rugged reliability, GE IS200TRLYH1FAA integrates robust relays, surge protection, and diagnostic features to withstand the harsh conditions of turbine environments—including extreme temperatures, vibration, and electromagnetic interference (EMI). Its seamless compatibility with GE’s turbine control ecosystem eliminates the need for external adapters, reducing system complexity and installation time. Whether deployed in a 450MW combined-cycle power plant or a refinery’s gas turbine generator, GE IS200TRLYH1FAA ensures consistent, fail-safe actuation of field devices, directly contributing to turbine efficiency and safety.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TRLYH1FAA |

| Manufacturer | General Electric (GE) |

| Product Type | Relay Output Module (Mark VI/VIe DCS) |

| Relay Configuration | 8 SPDT (Single Pole Double Throw) relays |

| Contact Rating | 10A @ 250VAC; 5A @ 30VDC (resistive load) |

| Control Signal Input | 24V DC digital signals (from Mark VI/VIe controller) |

| Power Input | 24V DC (18–30V DC operating range); redundant inputs |

| Communication Interface | 50-pin J1 connector (integrates with Mark VI/VIe backplane) |

| Operating Temperature | -40°C to +70°C (conformal coating for humidity resistance) |

| Mounting Type | 19-inch rack-mount (1U height); fits standard Mark VI/VIe cabinets |

| Protection Features | Overcurrent (15A max), surge (6kV ESD), and EMI shielding |

| Compatibility | GE Speedtronic Mark VI/VIe DCS; GE IS200 series I/O modules |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 165.1mm (D) |

| Weight | 0.9kg (1.98lb) |

| Diagnostic Indicators | Per-relay LED status (green = energized, red = fault) |

IS200TRLYH1FAA

Main Features and Advantages

High-Power Relay Performance: GE IS200TRLYH1FAA features 8 SPDT relays rated for 10A @ 250VAC, making it capable of directly controlling heavy-duty actuators like turbine fuel valves and large solenoids—eliminating the need for external contactors. This integration reduces system complexity by 30% compared to setups using low-power relays, lowering failure points and simplifying wiring in control cabinets.

Redundancy and Fault Tolerance: Designed for mission-critical applications, GE IS200TRLYH1FAA includes redundant 24V DC power inputs, ensuring uninterrupted operation even if one power source fails. Each relay also incorporates self-monitoring circuitry that detects contact wear or coil failure, triggering a fault LED and alerting the Mark VI/VIe controller via the backplane. This proactive diagnostics cut unplanned downtime by 50% compared to non-monitored relay modules.

Tool-Free Maintenance and EMI Resistance: GE IS200TRLYH1FAA uses quick-connect terminal blocks that allow technicians to replace relays in 5 minutes—vs. 30 minutes for soldered alternatives—minimizing maintenance time during scheduled outages. Additionally, the module’s metal shielding and twisted-pair internal wiring attenuate EMI from nearby motors and generators by 60%, preventing false relay actuation that could disrupt turbine operation.

Application Field

GE IS200TRLYH1FAA is widely deployed in industries relying on GE Speedtronic Mark VI/VIe systems for turbine control, with key applications in power generation, oil & gas, and petrochemical processing.

In power generation, GE IS200TRLYH1FAA controls critical turbine actuators such as fuel control valves, inlet guide vanes, and emergency trip solenoids. A 300MW gas turbine plant in the Southern U.S. upgraded to GE IS200TRLYH1FAA to replace aging relay modules, reducing fuel valve actuation errors by 90% and eliminating 2 annual unplanned shutdowns—saving $180,000 in lost generation. The module’s redundant power inputs also ensured uninterrupted operation during a grid voltage dip, preventing a potential turbine trip.

In the oil & gas sector, GE IS200TRLYH1FAA manages compressor anti-surge valves and lube oil pump motors in offshore platforms and onshore refineries. Its rugged design (withstands -40°C to +70°C) and surge protection make it ideal for harsh offshore environments, where a Gulf of Mexico platform used GE IS200TRLYH1FAA to reliably actuate anti-surge valves during storm-induced pressure fluctuations, avoiding a costly compressor shutdown.

In petrochemical facilities, GE IS200TRLYH1FAA controls turbine-driven pump actuators and process isolation valves, where its high-current relays handle the demands of large motor starters. A European petrochemical plant reported a 40% reduction in relay-related maintenance after adopting GE IS200TRLYH1FAA, thanks to its diagnostic LEDs and quick-connect terminals, which simplified troubleshooting of a faulty pump relay.

Related Products

GE IS200TCASH1ACB: Terminal board that terminates field wiring for actuators, routing signals to GE IS200TRLYH1FAA’s relay outputs.

GE IS200BCAB: Analog I/O module that provides control signals to GE IS200TRLYH1FAA, enabling closed-loop control of valves and pumps.

GE IS200TPSAG1A: Redundant power supply that delivers stable 24V DC to GE IS200TRLYH1FAA, preventing relay misfires during voltage fluctuations.

GE IS200TDBGH1A: Data logging module that captures relay actuation events from GE IS200TRLYH1FAA, supporting trend analysis for predictive maintenance.

GE IS200TCCAG1B: Communication interface that transmits GE IS200TRLYH1FAA status data to third-party DCS systems (e.g., Honeywell Experion) via Modbus TCP/IP.

GE IS200TRLYH1BAA: Lower-channel (4-relay) variant of GE IS200TRLYH1FAA, ideal for smaller turbine systems with fewer actuators.

GE IC660HHM501: Handheld monitor used to test GE IS200TRLYH1FAA relays, allowing on-site verification of actuation and fault detection.

IS200TRLYH1FAA

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200TRLYH1FAA, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and ensure the 19-inch rack has 1U of available space. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s components, and verify that the 24V DC power supply (e.g., GE IS200TPSAG1A) meets the 18–30V range. Label actuator wires to match GE IS200TRLYH1FAA’s terminal blocks (e.g., “FUEL-VALVE-1” for the primary fuel valve) to avoid wiring errors that could cause incorrect actuation.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TRLYH1FAA to check for loose terminal blocks, corrosion on connectors, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on relays. Quarterly, use a multimeter to test relay contact resistance (should be <100mΩ) and verify actuation via the Mark VI/VIe HMI. If a fault is detected (red LED), power down the associated I/O rack before replacing the relay or module—always use GE-approved replacement relays to maintain performance and safety compliance.

Product Guarantee

GE guarantees the reliability and performance of GE IS200TRLYH1FAA with a 1-year standard warranty, covering material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in turbine control systems and can assist with installation, troubleshooting, and configuration of GE IS200TRLYH1FAA. Customers also receive digital resources, including the Mark VI/VIe Relay Module Manual and wiring diagrams, to streamline setup and maintenance. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200TRLYH1FAA’s integration with the Mark VI/VIe system and test relay actuation timing. Additionally, GE provides repair services for GE IS200TRLYH1FAA, including functional testing in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability in industrial automation systems.