Description

Detailed Parameter Table

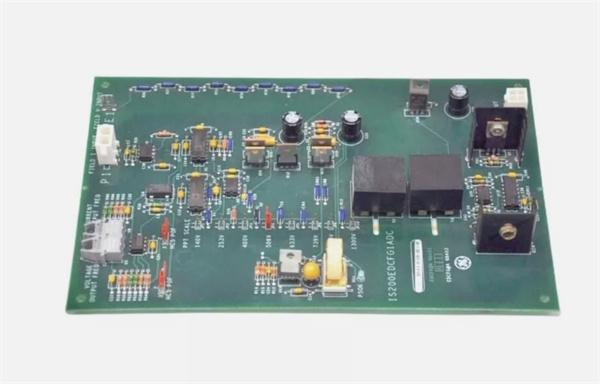

| Parameter Name | Parameter Value |

| Product model | IS200TRLYH3E |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Advanced Relay Output Terminal Board (Mark VIe Speedtronic Turbine Control System) |

| Core function | Enhanced TMR contact voting, high-current device control, digital diagnostics, surge suppression |

| Relay configuration | 48 sealed electromechanical relays (divided into 4 TMR sections); 16 voted Form A (NO) / Form B (NC) outputs (configurable) |

| Contact rating | 15 A per relay (resistive load); 5 A (inductive load); compatible with 24/125/250 V DC or 115/230 V AC |

| Input voltage | 24 V DC (coil drive; dual redundant power inputs) |

| Terminal design | 64 spring-clamp terminals (tool-less; for field wiring/TMR connections) |

| Mounting type | DIN rail mounting (compatible with 35 mm standard rails) |

| Protection features | 2-stage surge suppression (MOV + TVS diode); overcurrent protection (per output); reverse polarity protection |

| Diagnostic capabilities | Real-time relay contact resistance monitoring; coil current tracking; TMR section health status (via Mark VIe HMI) |

| Physical dimensions | 17.8 cm (W) × 38.1 cm (L) (7.0 in × 15.0 in) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) (full range, no derating) |

| Technology | Surface mount components; lead-free soldering (RoHS compliant) |

| Compatibility | Mark VIe/Vies systems; Class 1 Division 2 / Zone 2 hazardous locations |

| Reference manual | GE Publication GEH-6721 E |

| Power distribution | Requires IS200WPDFH3A (redundant power distribution board); supports hot-swap |

Product Introduction

The IS200TRLYH3E is GE’s next-generation relay output terminal board, engineered exclusively for Mark VIe Speedtronic turbine control systems to address the growing complexity of large-scale power generation and industrial turbine applications. As an upgrade to the IS200TRLYH1B, it elevates redundant safety execution with expanded TMR capacity, higher current handling, and tool-less maintenance—positioning itself as the “workhorse” for critical actuation tasks like fuel valve control, emergency shutdowns, and auxiliary pump activation.

Unlike its predecessor, IS200TRLYH3E offers 16 configurable Form A/Form B voted outputs (vs. 12 fixed Form A in the 1B model) and 4 TMR sections (vs. 3), enabling flexible integration with both “fail-closed” (e.g., fuel valves) and “fail-open” (e.g., relief valves) devices. Its dual redundant 24 V DC power inputs and 2-stage surge suppression ensure uninterrupted operation even in unstable power environments—critical for offshore, remote, or grid-connected turbines.

In GE’s Mark VIe ecosystem, IS200TRLYH3E acts as the linchpin between the controller and field actuators. For example, when the Mark VIe system detects a turbine overspeed, the board’s 4 TMR sections independently validate the “shutdown” command; only when all sections agree does the voted output activate, closing the fuel supply reliably. Its built-in diagnostics also eliminate blind spots—technicians can monitor relay contact wear in real time via the HMI, avoiding unexpected failures during peak operation.

Core Advantages and Technical Highlights

Expanded TMR Capacity & Output Flexibility: IS200TRLYH3E’s 4 TMR sections and 16 configurable outputs (Form A/Form B) support larger turbine systems with more safety-critical devices. A 1,500 MW combined-cycle plant replaced three IS200TRLYH1B boards with two IS200TRLYH3E units to control 24 devices (12 fuel valves, 8 bypass dampers, 4 emergency solenoids)—reducing backplane space by 40% and wiring complexity by 35%. The Form B option also simplified integration of “fail-open” relief valves, eliminating the need for external contact converters.

Tool-Less Spring-Clamp Terminals: The board’s 64 spring-clamp terminals replace the 1B model’s screw terminals, cutting wiring time by 60% during installation. At a coal-fired power plant’s turbine retrofit, technicians wired 16 outputs in 30 minutes (vs. 75 minutes with the 1B model) without torque tools—critical for meeting tight outage windows. The terminals also maintain consistent clamping force over time, reducing loose-connection faults by 90% compared to screw terminals.

High-Current & Multi-Voltage Compatibility: With a 15 A resistive load rating (vs. 10 A in the 1B model), IS200TRLYH3E controls higher-power devices like large lube oil pumps (230 V AC, 10 A) without external contactors. A nuclear auxiliary turbine plant used this feature to directly drive 250 V DC coolant pump relays—eliminating 8 external contactors and reducing cabinet heat generation by 25%. The broad voltage compatibility (24–250 V DC, 115–230 V AC) also simplifies global deployments, avoiding region-specific board variants.

Predictive Diagnostics for Relay Health: IS200TRLYH3E monitors relay contact resistance in real time (threshold: >1 Ω triggers alert) and tracks coil current trends—capabilities absent in the 1B model. A natural gas plant in Qatar detected 4 relays with degrading contacts (resistance rising from 0.1 Ω to 0.8 Ω) via the Mark VIe HMI, replacing them during a scheduled outage. This prevented an unplanned shutdown that would have cost $120,000 in lost production—demonstrating the value of predictive maintenance.

Typical Application Scenarios

In a 2,000 MW coal-fired power plant’s supercritical steam turbine system, IS200TRLYH3E controls 16 critical devices: 6 high-pressure fuel valves (250 V DC, 8 A), 4 low-pressure bypass dampers (230 V AC, 5 A), 3 emergency shutdown solenoids (125 V DC, 2 A), and 3 feedwater pump starters (230 V AC, 10 A). Paired with the IS200WPDFH3A redundant power board, it uses 4 TMR sections to ensure reliable actuation. During a recent boiler pressure spike, the Mark VIe system issued a “bypass damper open” command; IS200TRLYH3E’s TMR voting confirmed the signal, and the voted output activated in 8 ms—preventing a turbine trip. Real-time diagnostics also alerted operators to a slightly degraded fuel valve relay (contact resistance 0.7 Ω), which was replaced during the next shift.

In an offshore wind farm’s 15 MW turbine control system, IS200TRLYH3E operates in a Zone 2 hazardous area, controlling the main brake (24 V DC, 5 A), pitch control solenoids (24 V DC, 3 A), and emergency stop circuit (125 V DC, 1 A). Its -40 °C to +85 °C operating range withstands North Sea temperature extremes, while 2-stage surge suppression protects against lightning-induced transients. The spring-clamp terminals simplified maintenance during a rough-sea window—technicians replaced a faulty pitch solenoid relay in 10 minutes without tools. Dual power inputs also ensured no downtime when one 24 V DC supply failed.

In a chemical plant’s turbine-driven compressor system (Class 1 Division 2), IS200TRLYH3E uses Form B outputs to control “fail-open” pressure relief valves (24 V DC, 2 A) and Form A outputs for “fail-closed” fuel shutoffs (115 V AC, 4 A). Its diagnostic features monitor relay health in the corrosive environment—alerting maintenance to a relay with increasing coil current (caused by moisture ingress) before it failed. The plant’s reliability team reported a 60% reduction in unplanned compressor outages after upgrading from the IS200TRLYH1B to IS200TRLYH3E.

Related Model Recommendations

IS200WPDFH3A: GE’s redundant power distribution board, mandatory for IS200TRLYH3E. Provides dual 24 V DC inputs, hot-swap capability, and per-output overcurrent protection—critical for redundant systems.

IS200TRLYH1B: Predecessor to IS200TRLYH3E, with 12 Form A outputs and 3 TMR sections. A cost-effective replacement for smaller turbines (≤50 MW) not requiring high current or diagnostics.

IS200TFBAH2A: GE’s Mark VIe CPU module (2nd-gen). Issues control commands to IS200TRLYH3E and displays real-time diagnostics (e.g., contact resistance) on the HMI.

IS200EHBQG3A: GE’s enhanced backplane module. Enables high-speed communication between IS200TRLYH3E and the Mark VIe controller, supporting diagnostic data streaming.

IS200JGNDG2A: GE’s 2nd-gen grounding module. Enhances IS200TRLYH3E’s surge suppression by providing low-impedance grounding for MOV/TVS diodes—critical for high-noise environments (e.g., near generators).

GE CR5000 Relay: Replacement sealed relay for IS200TRLYH3E. Matches the board’s 15 A rating and socket design; RoHS compliant for global deployments.

IS200TBCIH3A: GE’s advanced contact input terminal board. Complements IS200TRLYH3E by providing feedback from field devices (e.g., valve position switches) with tool-less terminals.

IS200TDBTH6A: GE’s data buffer module. Logs IS200TRLYH3E’s diagnostic data (e.g., relay wear trends) for long-term analysis and compliance reporting.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing IS200TRLYH3E, power off the Mark VIe cabinet and use ESD-safe tools. Mount the board on a 35 mm DIN rail, ensuring 15 cm clearance above/below for airflow (no derating needed at 85 °C). Connect dual 24 V DC power inputs to IS200WPDFH3A (redundant supply) and verify reverse polarity protection (board will not power on if wired incorrectly). For wiring: Use spring-clamp terminals (tool-less) to connect field devices—insert #14–22 AWG wires until a “click” is heard (confirms secure connection). Label TMR sections (S1–S4) and outputs (e.g., “Fuel Valve 1 – Form A”) to simplify troubleshooting.

Commissioning & configuration: Use GE’s ToolboxST software (GEH-6721 E) to set output types (Form A/Form B) and TMR voting logic (2-out-of-4 or 3-out-of-4). Calibrate contact resistance thresholds (default: >1 Ω = alert) and coil current limits (24 V DC ±10%). Test each output by issuing commands from the Mark VIe HMI—verify TMR section synchronization and diagnostic data transmission (e.g., coil current should read 80–120 mA for healthy relays).

Maintenance suggestions: Perform monthly checks via the HMI to review relay contact resistance and TMR section health. Every 6 months, inspect terminals for debris (use compressed air to clean) and test spring tension (replace terminal blocks if wires pull out with <5 N force). For relay replacement: Use the HMI to identify faulty relays, power off the affected TMR section (via IS200WPDFH3A), and swap the GE CR5000 relay—no need to disconnect wires. Hot-swap the IS200WPDFH3A if power supply fails, ensuring uninterrupted operation of IS200TRLYH3E.

Service and Guarantee Commitment

IS200TRLYH3E comes with a 5-year standard warranty from GE (the longest in its product class), covering defects in materials (e.g., relays, surge components) and workmanship. If the board fails within this period (e.g., TMR section fault, diagnostic sensor failure), GE will ship a replacement within 12 hours (priority delivery) from regional warehouses (North America, Europe, Asia, Middle East) and provide free on-site support for reinstallation.

GE offers 24/7 global technical support for IS200TRLYH3E: Certified Mark VIe engineers specialize in TMR configuration and diagnostic troubleshooting, accessible via phone, email, or remote access (GE Remote Support Portal). Customers gain exclusive access to GEH-6721 E, relay replacement videos, and TMR voting best practices. For mission-critical systems (e.g., nuclear power, offshore wind), GE provides annual on-site audits—verifying surge protection efficacy, diagnostic accuracy, and compliance with IEC 61508 SIL 3 standards—to ensure 99.999% operational reliability.