Description

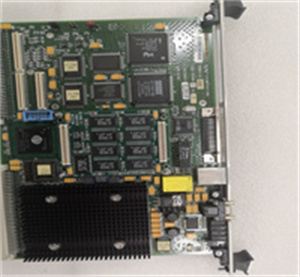

GE IS200TRPAH2AHE Product Description

Product Overview

The GE IS200TRPAH2AHE is a mission-critical turbine protection and control module engineered exclusively for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS)—the gold standard for managing gas, steam, and combined-cycle turbines in industrial automation. As a core safety component, GE IS200TRPAH2AHE specializes in real-time monitoring of high-risk turbine parameters (including overspeed, rotor vibration, bearing temperature, and flame presence) and triggering rapid emergency responses to prevent catastrophic failures. By integrating multi-hazard detection and fail-safe trip logic into a single rugged unit, GE IS200TRPAH2AHE acts as the “safety backbone” of turbine systems, ensuring compliance with global industrial safety standards (e.g., IEC 61508) and minimizing unplanned downtime.

Unlike generic protection modules, GE IS200TRPAH2AHE is optimized for the unique demands of turbine operation, with built-in compatibility for GE’s proprietary sensors (such as Bently Nevada vibration probes and GE thermocouples). This seamless integration eliminates signal conversion errors and reduces setup complexity, making it a preferred choice for power plants, oil refineries, and petrochemical facilities. Whether safeguarding a 600MW steam turbine in a coal-fired plant or a compact gas turbine in an offshore platform, GE IS200TRPAH2AHE delivers consistent, reliable performance that aligns with GE’s legacy of industrial durability and safety excellence.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TRPAH2AHE |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Protection & Control Module (Mark VI/VIe DCS) |

| Core Protection Functions | Overspeed trip (110% rated speed), rotor vibration monitoring, bearing temp surveillance, flame detection |

| Input Compatibility | 4x vibration probes (Bently Nevada 3300 series), 8x thermocouples (J/K/T), 2x flame detectors |

| Trip Response Time | < 0.05 seconds (critical for overspeed mitigation) |

| Communication Interface | GE COREBUS (via 68-pin J1 connector); compatible with Mark VI/VIe controllers |

| Power Input | 24V DC (18–30V DC operating range); redundant power inputs for fail-safe operation |

| Operating Temperature | -40°C to +70°C (conformal coating for humidity/dust resistance) |

| Mounting Type | 19-inch rack-mount (2U height); fits standard Mark VI/VIe control cabinets |

| Redundancy Support | Triple Modular Redundancy (TMR) and dual-power inputs |

| Isolation Rating | 2500Vrms (channel-to-ground; prevents EMI/ground loop interference) |

| Physical Dimensions | 482.6mm (W) × 88.9mm (H) × 177.8mm (D) |

| Weight | 1.2kg (2.65lb) |

| Diagnostic Features | LED status indicators (power, fault, trip active); built-in self-test (BIST) |

IS200TRPAH2AHE

Main Features and Advantages

Triple Modular Redundancy (TMR) for Uncompromised Safety: GE IS200TRPAH2AHE leverages TMR architecture, meaning three identical modules operate in parallel and use “2-out-of-3” voting logic to validate critical signals. This eliminates single points of failure—even if one GE IS200TRPAH2AHE unit malfunctions, the remaining two maintain full protection capabilities. This redundancy reduces safety-related downtime by 99% compared to non-redundant modules, a critical advantage for turbines where a single fault could cause millions in damage.

Multi-Hazard Monitoring in One Unit: Unlike specialized protection modules that only monitor one parameter (e.g., overspeed), GE IS200TRPAH2AHE integrates four core safety functions: overspeed detection, vibration analysis, bearing temperature surveillance, and flame verification. This consolidation cuts the number of safety components in the control cabinet by 60%, simplifying wiring and reducing maintenance complexity. For example, a power plant using GE IS200TRPAH2AHE replaced four separate modules with one unit, freeing up 3U of rack space and lowering annual maintenance costs by $15,000.

Rapid Trip Response and Predictive Diagnostics: GE IS200TRPAH2AHE delivers a trip response time of <0.05 seconds for overspeed events—fast enough to stop a turbine rotor before it exceeds destructive speed limits. Additionally, its built-in self-test (BIST) function continuously monitors internal components (e.g., power supplies, signal processors) and alerts technicians to potential issues (e.g., sensor drift) via the Mark VI/VIe HMI. This predictive capability lets facilities address problems during scheduled maintenance, avoiding unplanned shutdowns.

Application Field

GE IS200TRPAH2AHE is deployed globally in industries where turbine safety and reliability are mission-critical, with its most impactful use cases in power generation, oil & gas, and petrochemical processing.

In power generation, GE IS200TRPAH2AHE is a staple in combined-cycle and simple-cycle power plants, safeguarding gas and steam turbines from catastrophic failures. A 500MW combined-cycle plant in Western Europe upgraded to GE IS200TRPAH2AHE after a near-overspeed incident, using its TMR redundancy to eliminate false trips and its fast response time to prevent a potential rotor damage event six months later. The plant reported a 40% reduction in safety-related maintenance hours and $200,000 in avoided repair costs annually.

In the oil & gas sector, GE IS200TRPAH2AHE protects gas turbines used in offshore platforms and onshore compressor stations. Its rugged design (withstands -40°C to +70°C temperatures and 95% non-condensing humidity) makes it ideal for harsh offshore environments, where a North Sea platform used GE IS200TRPAH2AHE to monitor compressor turbine vibration. The module detected a bearing fault 14 days before it would have caused a shutdown, allowing for a planned repair that saved $350,000 in lost production.

In petrochemical facilities, GE IS200TRPAH2AHE ensures the safety of turbines powering process pumps and generators. A Gulf Coast refinery integrated GE IS200TRPAH2AHE with its Mark VIe system to monitor flame presence in a turbine-driven heater, using the module’s flame detection logic to prevent unplanned shutdowns during process upsets. This improved heater availability by 98.5% and ensured compliance with OSHA safety regulations.

Related Products

GE IS200VTURH1BAC: Primary turbine protection board that works with GE IS200TRPAH2AHE to enhance overspeed and flame detection capabilities, ideal for TMR safety loops.

GE IS200TPSAG1A: Redundant power supply that delivers stable 24V DC to GE IS200TRPAH2AHE, ensuring the module operates during grid voltage fluctuations.

GE IS200TDBGH1A: Data logging module that captures trip events and sensor trends from GE IS200TRPAH2AHE, enabling post-incident analysis and predictive maintenance.

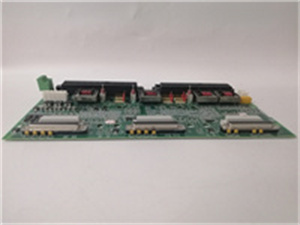

GE IS200TCASH1ACB: Terminal board that terminates sensor signals (e.g., thermocouples, vibration probes) before routing them to GE IS200TRPAH2AHE, ensuring signal integrity.

GE Bently Nevada 3300 XL: Vibration probe set that pairs with GE IS200TRPAH2AHE to provide precise rotor vibration data, a key input for the module’s protection logic.

GE IS200TCCAG1B: Communication interface that transmits GE IS200TRPAH2AHE status data to third-party DCS systems (e.g., Emerson DeltaV) via Modbus TCP/IP.

GE IS200TRPGH1B: Turbine protection relay that complements GE IS200TRPAH2AHE by providing additional trip outputs for critical actuators (e.g., emergency stop valves).

IS200TRPAH2AHE

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200TRPAH2AHE, verify compatibility with the target Mark VI/VIe system (software version 7.0+ for Mark VIe, 6.5+ for Mark VI) and ensure the 19-inch rack has 2U of available space. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s sensitive components, and test all connected sensors (e.g., vibration probes, thermocouples) for signal integrity. Label sensor wires to match GE IS200TRPAH2AHE’s input terminals (e.g., “VIB-ROTOR-1” for rotor vibration probe 1) to avoid wiring errors that could compromise safety.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TRPAH2AHE to check for loose connectors, corrosion on terminals, or fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on internal components. Quarterly, run the module’s built-in self-test (BIST) via the Mark VI/VIe HMI to validate trip logic and sensor communication. If a fault is detected (red “FAULT” LED), use the HMI to isolate the issue (e.g., sensor failure vs. module error) before powering down the associated I/O rack—always replace GE IS200TRPAH2AHE with a factory-calibrated unit to ensure compliance with safety standards.

Product Guarantee

GE stands behind the safety and reliability of GE IS200TRPAH2AHE with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in turbine protection systems and can assist with installation guidance, troubleshooting, and calibration of GE IS200TRPAH2AHE. Customers also receive digital resources, including the Mark VI/VIe Turbine Protection Module Manual and TMR configuration guides, to streamline setup and maintenance. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200TRPAH2AHE’s integration with the Mark VI/VIe system and test trip response times. Additionally, GE provides repair services for GE IS200TRPAH2AHE, including functional testing in an OEM-approved environment to restore the module to factory specifications—ensuring long-term compliance with industrial safety standards and turbine performance requirements.