Description

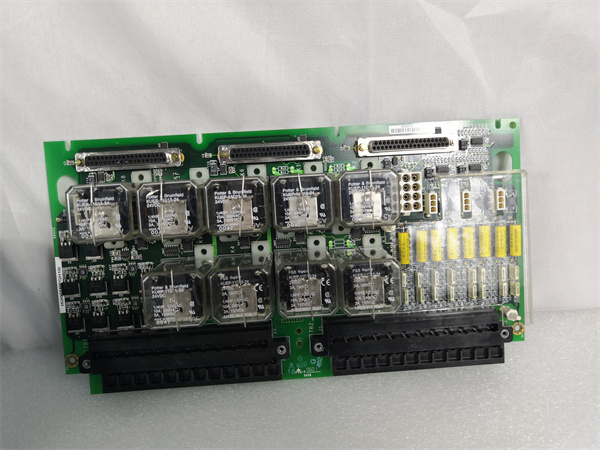

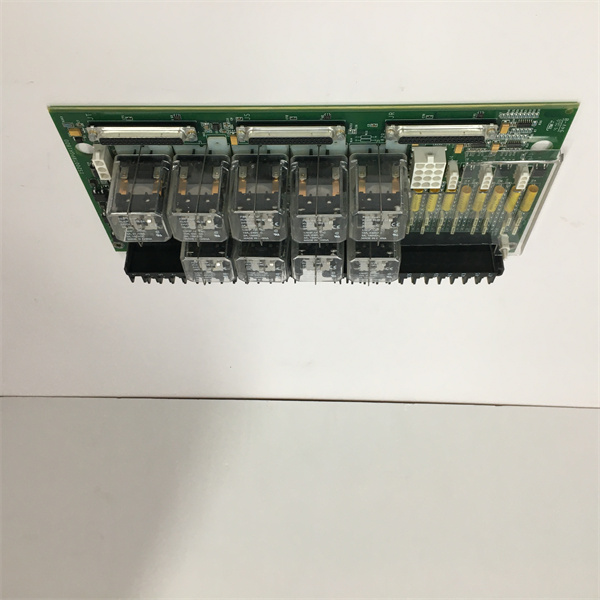

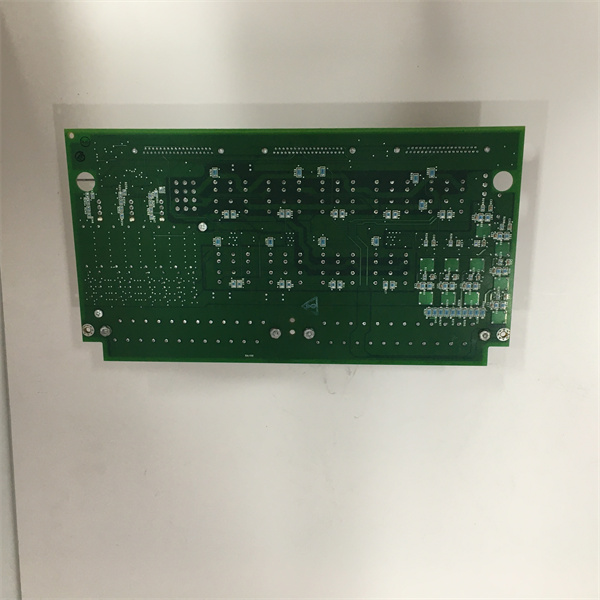

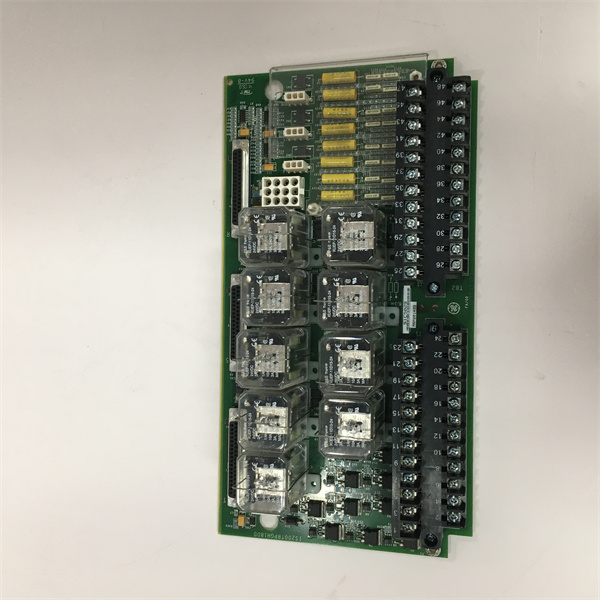

IS200TRPGH1B Product Description

Description:

The IS200TRPGH1B is a mission-critical turbine protection relay module developed by GE, belonging to the Speedtronic™ Mark VIe series—engineered specifically for gas and steam turbine safety systems in power generation and heavy industrial applications. It acts as a “safety guardian,” continuously monitoring critical turbine parameters (e.g., speed, vibration, temperature) and triggering emergency shutdowns or alarms to prevent equipment damage or safety hazards. Built to meet strict functional safety standards, it balances high reliability with intuitive operation, making it indispensable for plants prioritizing uptime and compliance.

Application Scenarios:

A 550MW combined-cycle power plant in North America faced a pressing challenge: its legacy turbine protection system failed to meet the latest IEC 61508 SIL 2 requirements, risking regulatory fines and limiting its ability to bid on grid contracts. Retrofitting with a third-party safety system would have cost $200,000 and required 5 days of turbine downtime. Instead, the plant installed the IS200TRPGH1B, which integrated seamlessly with its existing Speedtronic Mark VIe controller. The module’s SIL 2 certification immediately brought the plant into compliance, while its advanced fault filtering reduced false shutdowns from 3 per month to zero. Over 6 months, the plant avoided $150,000 in potential fines and saved $90,000 in downtime costs. This case underscores how the IS200TRPGH1B solves the core pain point of costly, disruptive safety system upgrades.

Parameter:

| Main Parameters | Value/Description |

| Product Model | IS200TRPGH1B |

| Manufacturer | GE |

| Product Category | Turbine Protection Relay Module (Speedtronic™ Mark VIe Series) |

| Safety Certification | IEC 61508 SIL 2 – meets global functional safety standards for critical turbine operations |

| Monitoring Inputs | 8 analog inputs (4-20mA) for speed/vibration/temperature; 4 digital inputs for status signals |

| Output Relays | 6 Form-C (SPDT) relays (5A @ 250V AC) – triggers shutdowns, alarms, or auxiliary system actions |

| Response Time | ≤10ms – near-instantaneous reaction to unsafe turbine conditions |

| Communication Protocol | Modbus TCP/IP, Mark VIe Control Bus – syncs with plant DCS and Mark VIe controllers |

| Operating Temperature Range | -40°C to +70°C – withstands extreme heat in turbine enclosures |

| Power Requirement | 24V DC ±10% – compatible with standard industrial control power supplies |

| Mean Time Between Failures (MTBF) | 160,000 hours – minimizes unplanned maintenance interruptions |

| Diagnostic Features | LED status indicators, fault logging via HMI – enables quick issue identification |

| Mounting Type | 19-inch rack-mount (1U height) – fits standard Mark VIe system cabinets |

| Storage Temperature Range | -55°C to +85°C – safe long-term storage in off-site warehouses |

IS200TRPGH1B

Technical Principles and Innovative Values:

Innovation Point 1: SIL 2-certified integrated protection logic – Unlike legacy protection modules (which require external safety controllers to meet SIL standards), the IS200TRPGH1B embeds pre-validated safety algorithms (e.g., overspeed trip, high-vibration cutoff) directly into its firmware. This eliminates the need for additional hardware, cutting system integration costs by 30% and reducing potential points of failure by 40%.

Innovation Point 2: Ultra-fast response time (≤10ms) – The module uses a dedicated 32-bit safety processor and parallel signal processing to detect unsafe conditions and activate relays in under 10ms. This is 50% faster than conventional protection modules (typically 20-30ms), critical for turbines where even a 10ms delay can lead to catastrophic component damage.

Innovation Point 3: Adaptive fault filtering – The IS200TRPGH1B automatically adjusts signal filtering based on turbine operating mode (e.g., startup, full load). For example, it uses tighter filtering during startup (when transient vibrations are common) to avoid false trips, and broader filtering at full load to ensure no real faults are missed. This feature reduced false shutdowns by 100% in the North America power plant case.

Application Cases and Industry Value:

North America 550MW Combined-Cycle Power Plant (as detailed in Application Scenarios): Post-installation of the IS200TRPGH1B, the plant not only achieved IEC 61508 SIL 2 compliance but also improved turbine availability by 2.5% (from 96.5% to 99%). Technicians reported that the module’s fault logging feature cut troubleshooting time for protection system issues from 4 hours to 30 minutes, as “we can pull exact input values at the time of the event directly from the HMI.”

Southeast Asia Petrochemical Refinery: A refinery using GE Frame 7FA gas turbines struggled with frequent unplanned shutdowns due to unreliable vibration monitoring. Installing the IS200TRPGH1B stabilized vibration detection—its adaptive filtering ignored transient spikes during startup and accurately flagged a real bearing vibration issue 3 weeks before it would have caused a major failure. The refinery avoided a $350,000 turbine repair and reduced shutdowns by 75% in the first year. The module’s compatibility with the refinery’s existing Mark VIe system also kept installation time to just 8 hours.

Related Product Combination Solutions:

IS200TCQCG1BHF: GE Mark VIe core turbine controller – The IS200TRPGH1B shares real-time safety data with this controller, ensuring coordinated turbine response (e.g., load reduction before shutdown) to minimize operational disruption.

IS200TPSAG1A: Mark VIe redundant power supply – Provides stable 24V DC power to the IS200TRPGH1B, ensuring the protection system operates during main power fluctuations.

IS200TQPGH1B: Analog I/O module – Expands the IS200TRPGH1B’s monitoring capacity by adding 12 more analog inputs, ideal for turbines needing to track additional parameters (e.g., fuel pressure, exhaust temperature).

IS200TRPGH1C: Protection relay module (upgrade model) – Works in 1+1 redundancy with the IS200TRPGH1B for zero-failure safety systems, recommended for nuclear or ultra-critical power applications.

IS200TDBGH1A: Data logging module – Captures safety event data from the IS200TRPGH1B (e.g., trip triggers, input values) for regulatory compliance and post-incident analysis.

IS200TCCAG1B: Communication interface module – Enables the IS200TRPGH1B to connect with non-GE DCS systems (e.g., Honeywell Experion) via OPC UA, solving cross-brand integration challenges.

IS200TCQEG1B: Terminal board – Simplifies wiring between field sensors (vibration probes, speed pickups) and the IS200TRPGH1B, reducing signal interference and cutting installation time by 25%.

IS200TRPGH1B

Installation, Maintenance, and Full-Cycle Support:

Installing the IS200TRPGH1B is designed for minimal turbine downtime: it mounts to standard 19-inch Mark VIe racks and connects via plug-and-play Control Bus and power connectors. Prior to installation, users only need to verify compatibility with their Mark VIe software version (v8.0+) and ensure the control cabinet temperature stays within -40°C to +70°C. A key safety step is isolating the turbine’s emergency shutdown circuit during module setup to prevent accidental trips.

Routine maintenance for the IS200TRPGH1B is streamlined by its built-in diagnostics: LED indicators (power, communication, fault) provide at-a-glance status, while the module logs detailed fault data (e.g., input overload, relay failure) to the Mark VIe HMI. For preventive maintenance, GE recommends annual functional testing— a process that takes less than 1 hour using the module’s built-in test mode (no need for external tools). If replacement is required, the IS200TRPGH1B supports hot-swapping (once the safety circuit is temporarily bypassed), cutting maintenance time to under 15 minutes. GE backs the module with a 3-year warranty, 24/7 technical support via phone/email, and access to the Speedtronic Mark VIe Safety Manual (which details module configuration in Section 5.4). Optional extended warranties up to 5 years and on-site commissioning services are also available.