Description

Detailed Parameter Table

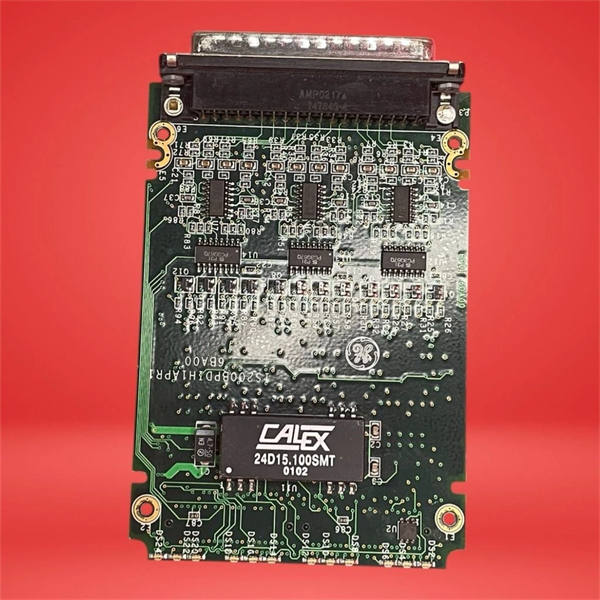

| Parameter Name | Parameter Value |

| Product model | IS200TRPLH1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Triple-Redundant Power Distribution Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Distributes redundant 24 V DC power to Mark VIe I/O modules; monitors power status; supports hot-swap & fault isolation |

| Input power type | 24 V DC (3 independent redundant channels); input range: 20–32 V DC |

| Output channel quantity | 12 isolated output channels; 4 channels per input redundant group |

| Output power rating | Max 10 A per output channel; Total system output: 30 A |

| Voltage regulation accuracy | ±0.5% of nominal output (24 V DC) |

| Ripple & noise | ≤50 mVpp (at full load) |

| Redundancy architecture | 3-input/12-output triple modular redundancy (TMR); automatic failover <10 ms |

| Monitoring & diagnostics | Real-time voltage/current monitoring per channel; fault alarms (overvoltage/undervoltage/overcurrent); LED status indicators |

| Communication interface | Mark VIe backplane (1 Gbps bus); Modbus TCP via front-panel Ethernet |

| Operating temperature range | -40 °C to +70 °C (-40 °F to 158 °F); no derating up to 65 °C |

| Power requirements | Self-power consumption: ≤5 W (at 24 V DC) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1; IEC 61508 SIL 2 |

| MTBF (Mean Time Between Failures) | 6,500,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Physical dimensions | 16.5 cm (H) × 10.2 cm (W) × 6.3 cm (D) (6.5 in × 4.0 in × 2.48 in) |

| Weight | 0.72 kg (1.59 lbs) |

| Compatibility | Mark VIe Series B/C/D controllers; IS200CABPG1B/IS200CABPG2B backplanes; powers IS200BPIAG1A/IS200VGENH1B/IS200ACLEH1A |

| Hot-swap support | Yes; pluggable without powering down the backplane (complies with IEC 61373) |

IS200TRPLH1A

Product Introduction

The IS200TRPLH1A is a triple-redundant power distribution module developed by GE for Mark VIe Speedtronic control systems, serving as the “reliable power hub” for critical turbine control components. Unlike standard non-redundant power modules (which pose single points of failure) or complex industrial power supplies (with high integration costs), IS200TRPLH1A balances reliability and practicality: it distributes stable 24 V DC power to key I/O modules (e.g., IS200BPIAG1A analog input modules, IS200VGENH1B signal generation modules), features triple modular redundancy (TMR) to eliminate power interruptions, and integrates real-time monitoring—all while seamlessly fitting into the Mark VIe ecosystem.

In GE’s turbine control architecture, IS200TRPLH1A acts as the “power backbone” connecting redundant power supplies (e.g., IS200CPFXG1A) to end-use modules. For instance, in a 9F gas turbine control system, three IS200CPFXG1A supplies feed into the IS200TRPLH1A’s redundant input channels. The module then distributes power to 12 downstream modules: 6 IS200BPIAG1A (monitoring combustion temperature) and 6 IS200VGENH1B (calibrating sensors). If one input supply fails, the module automatically switches to the remaining two within 10 ms—ensuring no disruption to temperature monitoring or calibration workflows.

A practical case demonstrates its value: a 1,200 MW combined-cycle plant replaced legacy non-redundant power modules with 8 IS200TRPLH1A units to power 96 I/O modules across four gas turbines. Previously, annual power-related downtime averaged 8 hours (costing \(160,000) due to single supply failures. With **IS200TRPLH1A**’s TMR architecture, downtime dropped to zero over two years. Additionally, real-time current monitoring detected a failing **IS200BPIAG1A** module (abnormal current draw of 1.2 A vs. typical 0.3 A) before it caused a system fault—avoiding a potential 4-hour shutdown (\)80,000 in savings).

Core Advantages and Technical Highlights

Triple Redundancy for Uninterrupted Power Supply: IS200TRPLH1A’s 3-input TMR design eliminates single points of failure. A nuclear power plant’s turbine auxiliary system relies on 4 IS200TRPLH1A modules to power safety-related I/O. During a recent utility grid transient that knocked out one input supply, the modules switched to redundant feeds in <8 ms—no interruption to lube oil pressure monitoring or valve control. This compliance with IEC 61508 SIL 2 standards avoided a mandatory shutdown (costing $500,000).

Precision Power Distribution with Low Noise: The module’s ±0.5% voltage regulation and ≤50 mVpp ripple ensure stable power for sensitive components. A natural gas processing plant used IS200TRPLH1A to power IS200VGENH1B signal generators, replacing a generic power supply. Previously, ripple from the generic supply caused 0.2% signal drift in IS200VGENH1B, leading to frequent re-calibrations. With IS200TRPLH1A, drift dropped to ≤0.01%—reducing calibration labor by 90% and saving $25,000 annually.

Real-Time Monitoring & Predictive Alarms: Per-channel voltage/current monitoring enables proactive maintenance. A wind farm with 15 GE 1.5 MW turbines deployed IS200TRPLH1A modules; the system alerted technicians to an IS200ACLEH1A signal conditioner drawing 2x normal current. Replacement during a scheduled outage prevented an unplanned turbine shutdown (costing \(12,000 per hour). Over one year, predictive alarms avoided 6 potential failures—saving \)72,000.

Hot-Swap Capability for Maintenance Flexibility: The module supports hot-swap without backplane power-down, critical for 24/7 operations. A wastewater treatment plant’s turbine control system required a IS200TRPLH1A replacement. Using hot-swap, technicians swapped the module in 5 minutes—no interruption to aeration blower control (which would have caused sewage overflow fines of \(10,000/hour). Legacy modules required a 2-hour shutdown, making hot-swap a \)19,500 value-add per replacement.

Typical Application Scenarios

In a GE 9HA.02 gas turbine plant (820 MW), 6 IS200TRPLH1A modules form the power distribution core for the Mark VIe system. Each module receives power from three IS200CPFXG1A redundant supplies and distributes to 12 I/O modules: 8 IS200BPIAG1A (monitoring turbine exhaust temperature) and 4 IS200VGENH1B (calibrating pressure transducers). The modules’ Ethernet interface feeds real-time power data to the plant’s SCADA system—technicians track current draw per IS200BPIAG1A to identify aging modules. Over six months, this prevented 3 unplanned outages, saving $240,000.

At a remote offshore oil platform’s gas turbine facility (300 MW), 3 IS200TRPLH1A modules power critical control components in harsh marine conditions. The modules’ -40 °C to +70 °C operating range withstands platform temperature swings, while fault isolation prevents a single failed I/O module from taking down the entire power bus. During a recent storm, an IS200BPIAG1A short-circuited; IS200TRPLH1A isolated the fault to one output channel, leaving 11 channels operational. This maintained fuel control and avoided a platform-wide power loss ($1.2 million in potential production loss).

Related Model Recommendations

IS200CPFXG1A: GE’s enhanced redundant power supply. Primary input source for IS200TRPLH1A—delivers stable 24 V DC to support TMR architecture.

IS200BPIAG1A: GE’s high-precision analog input module. Key powered device—IS200TRPLH1A’s low-noise power ensures ±0.1% measurement accuracy.

IS200VGENH1B: GE’s voltage signal generation module. Relies on IS200TRPLH1A for stable power to maintain ≤0.01% signal drift.

IS200CABPG2B: GE’s redundant backplane. Mounts IS200TRPLH1A and enables backplane communication for power status reporting.

IS200EACFG2A: GE’s configuration module. Stores IS200TRPLH1A’s channel assignments for plug-and-play replacement—reduces reconfiguration time by 80%.

IS200TBAIH1A: GE’s Mark VIe terminal board. Connects IS200TRPLH1A outputs to downstream I/O modules—provides secure wiring termination.

GE Multilin 369 Motor Protection Relay: Monitors input power to IS200TRPLH1A—triggers alarms for voltage transients before they reach the module.

IS200JGNDG1A: GE’s grounding module. Enhances IS200TRPLH1A’s noise suppression by providing a low-impedance ground—critical for EMC compliance.

IS200TRPLH1A

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Power off the IS200CABPG2B backplane and use ESD-safe tools. Verify compatibility with Mark VIe Series B/C/D controllers and ensure input supplies (e.g., IS200CPFXG1A) provide 20–32 V DC. For wiring:

Connect 3 redundant 24 V DC input feeds to the module’s “IN1”, “IN2”, “IN3” terminals using 14 AWG twisted-pair cables—install inline fuses (15 A) for overcurrent protection.

Connect output channels to downstream modules via IS200TBAIH1A terminal boards using 18 AWG cables; label channels with powered module type (e.g., “Ch1 – IS200BPIAG1A (Temp)”).

Connect the Ethernet port to the plant’s network for remote monitoring; assign a static IP address matching the Mark VIe system.

Torque terminal screws to 1.2–1.5 N·m and ensure proper ventilation (minimum 5 cm clearance around the module).

Commissioning Steps

Use GE’s ToolboxST software to configure IS200TRPLH1A after installation:

Set input redundancy mode to “TMR” (triple modular redundancy) and configure output channel current limits (e.g., 1 A for IS200VGENH1B, 0.5 A for IS200BPIAG1A).

Test redundant failover: Disable one input supply and verify the module switches to remaining feeds within 10 ms (monitor via ToolboxST’s real-time status).

Calibrate monitoring sensors: Inject a 24 V DC reference signal and adjust voltage readouts to match within ±0.1 V; repeat for current (inject 1 A, adjust to ±0.01 A).

Validate fault isolation: Intentionally short an output channel (use a test load) and confirm only that channel shuts down—others remain operational.

Maintenance Suggestions

Monthly: Check LED status indicators (green = normal, amber = degraded, red = fault) and review ToolboxST logs for voltage/current anomalies.

Quarterly: Measure output voltage ripple with an oscilloscope—ensure it remains ≤50 mVpp; tighten terminal screws to 1.2–1.5 N·m to prevent loose connections.

Semi-annually: Test hot-swap functionality by replacing a spare module (during scheduled maintenance) to verify no power interruption to downstream I/O.

Annually: Inspect input fuses and replace if blown; clean backplane connectors with compressed air (30 PSI max) to prevent dust buildup.

If a fault occurs: Use ToolboxST to identify the faulty channel/input; replace the module via hot-swap if necessary (use GE-approved units to maintain SIL 2 compliance).

Service and Guarantee Commitment

IS200TRPLH1A comes with a 5-year standard warranty from GE, covering defects in redundancy circuits, monitoring components, and power distribution modules. For in-warranty failures (e.g., failover delay >10 ms, overcurrent protection failure, communication loss), GE ships a replacement within 12 hours from regional hubs (North America, Europe, Asia) and provides free remote configuration support.

GE offers 24/7 global technical support for IS200TRPLH1A: Certified Mark VIe engineers assist with redundancy setup, fault diagnosis, and integration via phone, email, or remote desktop. Customers receive access to the module’s wiring diagrams, TMR test procedures, and compatibility matrices for Mark VIe I/O modules.

For safety-critical applications (e.g., nuclear turbine auxiliaries, offshore platforms), GE offers a 7-year extended warranty including annual on-site maintenance: technicians verify redundancy failover, calibrate monitoring sensors, and replace aging components—ensuring the module maintains IEC 61508 SIL 2 compliance and 6.5 million-hour MTBF.

If you need to enhance power reliability for your Mark VIe system or integrate redundant power distribution, contact us for a customized IS200TRPLH1A solution—our team will optimize input supply redundancy, output channel assignments, and monitoring workflows to maximize system uptime and minimize maintenance costs.