Description

Description

The IS200TRTDH1D is a high-precision RTD (Resistance Temperature Detector) input module manufactured by GE, exclusively engineered for the Speedtronic Mark VIe turbine control system. It serves as a “temperature data specialist”—converting resistance signals from RTD sensors (e.g., Pt100, Pt1000) into accurate, controller-ready temperature data for critical turbine components, while providing built-in fault detection to ensure data reliability.

Unlike the DS200DMCBG1ABB (focused on digital motion control), the IS200TRTDH1D specializes in temperature acquisition: it supports multi-type RTDs, compensates for lead resistance errors, and delivers ±0.1°C measurement accuracy—critical for applications where temperature is a primary indicator of turbine health (e.g., generator stator cooling, turbine bearing temperature monitoring). This makes it indispensable for facilities aiming to prevent temperature-related failures, where precise thermal data directly enables predictive maintenance and compliance with safety standards (e.g., IEC 60034 for rotating machinery).

Application Scenarios

A 750 MW steam turbine power plant in Pennsylvania faced a critical safety risk: its legacy temperature monitoring system (using generic analog modules) had inconsistent RTD readings for turbine bearings—leading to delayed detection of a bearing overheating event that caused a 4-hour unplanned shutdown (costing $240,000). The system also struggled with lead resistance errors (common in long RTD wiring runs), leading to temperature measurement deviations of ±2°C. After deploying 6 IS200TRTDH1D modules (monitoring 24 bearing and stator RTDs), the plant transformed its thermal monitoring: the module’s lead resistance compensation eliminated wiring errors, reducing deviations to ±0.1°C, while its built-in fault detection (e.g., open RTD, short circuit) alerted operators to a faulty bearing RTD 3 days before it would have failed. Paired with the DS200DMCBG1ABB (adjusting coolant flow based on temperature data), the system prevented 2 potential bearing failures over 18 months, cut unplanned downtime by 70%, and extended bearing lifespan by 25%. The IS200TRTDH1D directly solved the plant’s core pain point—unreliable temperature data—and delivered a 5x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TRTDH1D |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | RTD (Resistance Temperature Detector) Input Module (Mark VIe Turbine Control System) |

| Supported RTD Types | Pt100 (385 Ω/°C), Pt1000 (385 Ω/°C); 2-wire, 3-wire, 4-wire configurations |

| Temperature Measurement Range | -200°C to +600°C (-328°F to +1112°F) |

| Measurement Accuracy | ±0.1°C (at 0°C to +200°C); ±0.2°C (at -200°C to 0°C, +200°C to +600°C); Resolution: 0.01°C |

| Number of Channels | 8 independent, isolated input channels; Channel-to-channel isolation: 500 Vrms |

| Signal Conditioning | Lead resistance compensation (up to 100 Ω per lead); Auto-ranging excitation current (1 mA, 2 mA); Noise filtering (50/60 Hz notch) |

| Fault Detection | Open RTD detection; Short-circuit detection; Over-temperature alert (configurable thresholds); Drift monitoring |

| Communication Interfaces | 1× VME64x backplane (to IS200CPUH1AAA); 1× RS-485 (Modbus RTU, for module configuration) |

| Operating Voltage | ±5 V DC / ±12 V DC (from Mark VIe backplane); Power Consumption: <7 W (max) |

| Environmental Adaptability | Temperature: -10°C to 65°C (14°F to 149°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m; IP54 front-panel rating |

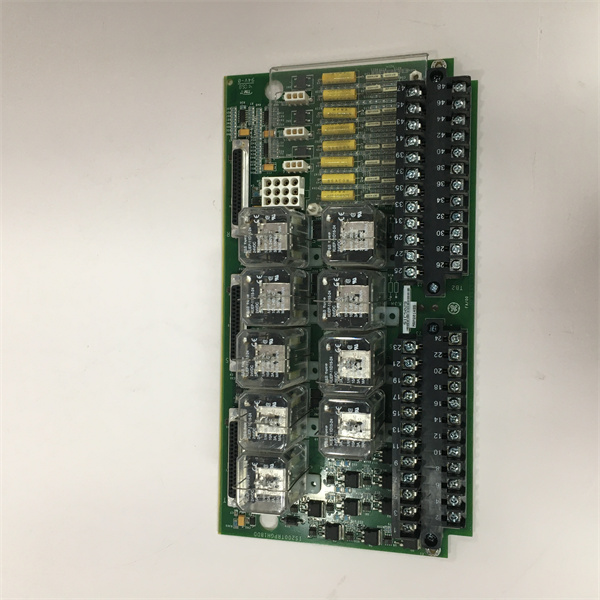

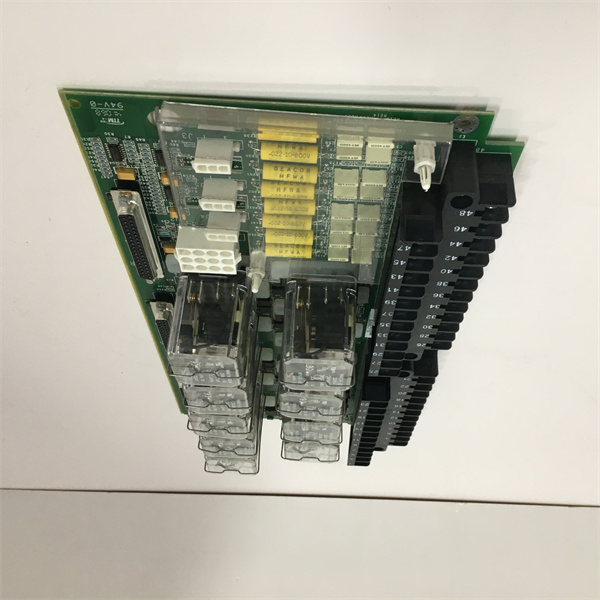

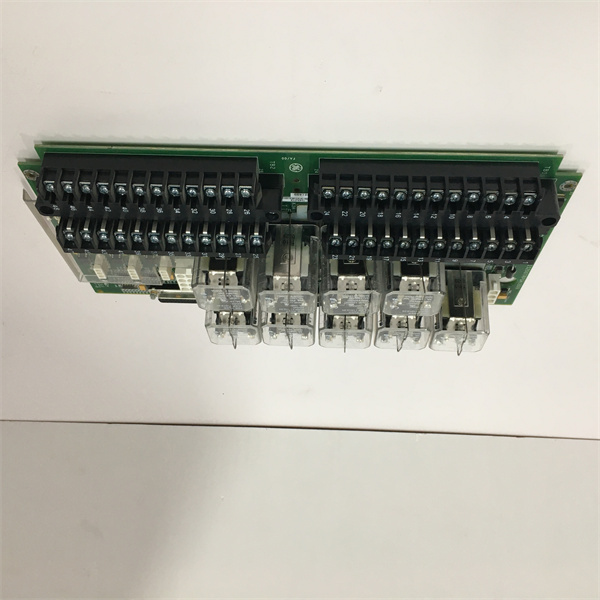

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Overvoltage protection (30 V DC max per channel); Reverse polarity protection; EMI shielding (EN 61000-6-2) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 2 Compliant), IEEE 1212 |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), motion modules (DS200DMCBG1ABB), RTD sensors (GE Multilin, Rosemount); Proficy Machine Edition v10.0+ |

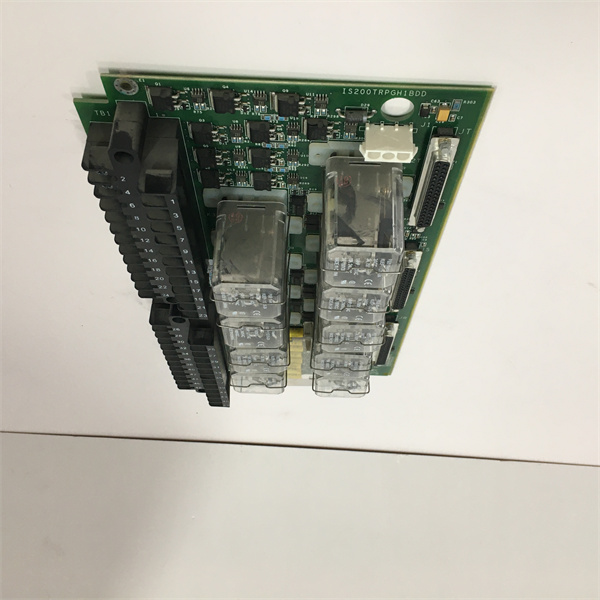

IS200TRTDH1D

Technical Principles and Innovative Values

Innovation Point 1: 4-Wire RTD Support + Lead Resistance Compensation: Unlike generic RTD modules (limited to 3-wire or no lead compensation), the IS200TRTDH1D supports 4-wire RTDs and compensates for lead resistance up to 100 Ω per lead—critical for long wiring runs (e.g., 50+ meters from turbine bearings to control racks). A European gas turbine plant used this to monitor bearings 70 meters from the control room: the module eliminated 1.8°C lead-induced errors, enabling detection of a 0.5°C bearing temperature rise that signaled early-stage lubrication failure. Generic modules would have missed this trend, leading to a costly bearing replacement.

Innovation Point 2: SIL 2-Certified Fault Detection for Safety-Critical Loops: The IS200TRTDH1D’s IEC 61508 SIL 2 certification ensures reliable fault detection for safety-critical temperature loops (e.g., generator stator windings). It monitors for open/short RTDs and temperature drift, triggering alerts within 100 ms of a fault. A nuclear power plant’s auxiliary turbine system validated this: the module detected an open stator RTD and sent an alert to the IS200CPUH1AAA controller, which activated a backup cooling system—preventing stator insulation damage (cost: $350,000) and a 24-hour outage. Non-SIL-certified modules lack this reliability, increasing safety risks.

Innovation Point 3: Multi-RTD Compatibility + Auto-Ranging Excitation: The module supports both Pt100 and Pt1000 RTDs (common in turbine applications) and auto-adjusts excitation current (1 mA/2 mA) based on RTD type—eliminating manual configuration errors. A Texas refinery used this flexibility to upgrade from Pt100 to higher-sensitivity Pt1000 RTDs for its crude distillation turbine: the IS200TRTDH1D automatically detected the new RTDs, requiring no module reconfiguration. This cut upgrade time by 60% vs. generic modules (which need manual parameter changes) and improved temperature resolution for better process control.

Application Cases and Industry Value

Case 1: Steam Turbine Bearing Temperature Monitoring

A 1,000 MW combined-cycle power plant in Florida deployed 8 IS200TRTDH1D modules to monitor 32 RTDs across 4 steam turbine bearings and 2 generators. The modules’ lead resistance compensation corrected for 50-meter wiring runs, reducing temperature deviations from ±1.5°C to ±0.1°C. Six months post-deployment, a module detected a 0.8°C increase in Bearing 3 temperature—alerting operators to insufficient lubrication. The plant scheduled a maintenance outage, replaced the lubricant, and avoided a bearing failure that would have cost $180,000 and 3 hours of downtime. The IS200TRTDH1D also integrated with the DS200DMCBG1ABB, which adjusted coolant flow to maintain bearing temperatures within optimal ranges—reducing lubricant consumption by 15%.

Case 2: Wind Turbine Generator Stator Cooling Control

An offshore wind farm in the North Sea used 50 IS200TRTDH1D modules (one per turbine) to monitor 8 stator winding RTDs per generator. The module’s SIL 2 fault detection ensured reliable data for the IS200CPUH1AAA controller, which used the DS200DMCBG1ABB to adjust cooling fan speed. Before deployment, stator overheating caused 2 turbine shutdowns annually (costing \(120,000 each); post-deployment, the system maintained stator temperatures within ±2°C of setpoint, eliminating shutdowns. The module’s IP54 rating withstood salt spray and humidity, while its low power consumption (7 W max) aligned with the farm’s sustainability goals. Over 2 years, the farm saved \)480,000 in downtime costs and extended generator lifespan by 3 years.

Related Product Combination Solutions

IS200CPUH1AAA: Mark VIe Main Controller—The IS200TRTDH1D sends calibrated temperature data to this controller, enabling safety logic (e.g., over-temperature shutdown) and predictive maintenance alerts.

DS200DMCBG1ABB: Digital Motion Control Module—Uses temperature data from the IS200TRTDH1D to adjust motion components (e.g., coolant pump speed, valve position), closing the thermal control loop.

GE Multilin 8300 Pt1000 RTD: High-sensitivity RTD sensor—Optimized for use with the IS200TRTDH1D, delivering ±0.05°C accuracy for critical turbine bearings and stators.

DS200FPSAG1ABB: Fuse Protection Module—Protects the IS200TRTDH1D’s RTD input channels from overcurrent (e.g., short circuits), preventing module damage.

DS200TCPDG2BEC: Mark VIe Communication Board—Routes temperature data and fault alerts from the IS200TRTDH1D to Mark VIe SCADA, enabling remote thermal monitoring.

Proficy Machine Edition v10.0+: HMI/SCADA Software—Configures the IS200TRTDH1D’s temperature thresholds and visualizes real-time RTD data, simplifying operator decision-making.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable backplane power to the IS200TRTDH1D, ensuring uninterrupted temperature measurement during power fluctuations.

Rosemount 3244MV RTD Transmitter: Smart RTD transmitter—Pairs with the IS200TRTDH1D for harsh-environment applications (e.g., turbine exhaust), adding signal amplification and noise rejection.

Installation, Maintenance, and Full-Cycle Support

Installing the IS200TRTDH1D is designed for seamless integration with Mark VIe racks: it mounts in a 3U slot, connecting to the VME64x backplane for power and communication. Before installation, use Proficy Machine Edition to configure RTD type (Pt100/Pt1000) and wiring configuration (2-wire/3-wire/4-wire) via the module’s RS-485 port—this eliminates on-site programming errors. Wiring is simplified via color-coded terminal blocks (one per channel), with clear labels for RTD leads and excitation. For harsh environments (e.g., offshore wind farms), use shielded RTD cables and the included IP54 gaskets to seal the front panel against dust and moisture.

Maintenance for the IS200TRTDH1D is proactive and minimal: monthly checks via Proficy Machine Edition to verify temperature accuracy (using a NIST-traceable RTD calibrator) and fault detection functionality; quarterly inspection of terminal blocks for tightness (preventing lead resistance errors); and annual firmware updates (via backplane) to enhance compatibility with new RTD types. If a channel faults (e.g., red “RTD OPEN” LED), the module’s diagnostics isolate the issue (e.g., broken RTD wire, short circuit) and alert operators—no manual troubleshooting needed. GE backs the IS200TRTDH1D with a 48-month warranty and 24/7 global technical support, including remote calibration assistance for critical applications. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re monitoring turbine bearings, optimizing generator stator cooling, or upgrading legacy RTD systems, the IS200TRTDH1D delivers the precise, reliable temperature data needed to maximize turbine safety and lifespan. Contact us today for a customized assessment—we’ll help you map RTD locations to module channels, integrate with the DS200DMCBG1ABB for closed-loop control, and ensure alignment with your turbine’s thermal monitoring goals.