Description

Product Overview

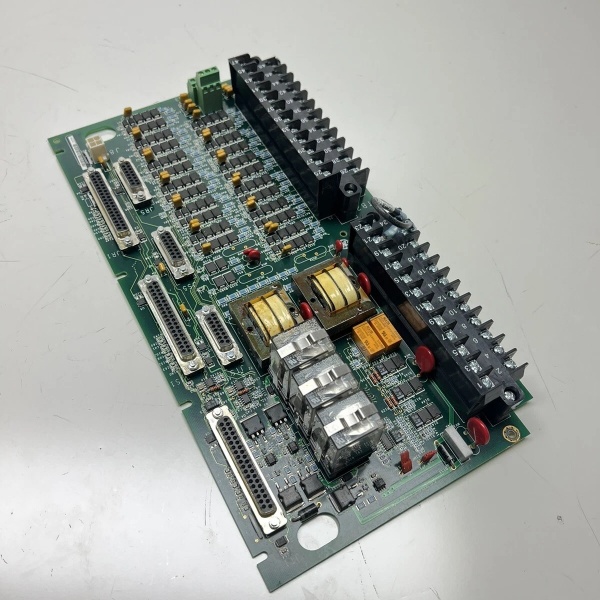

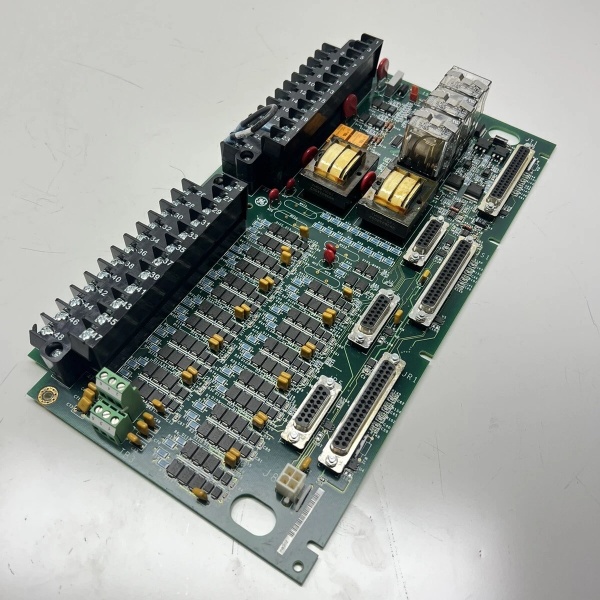

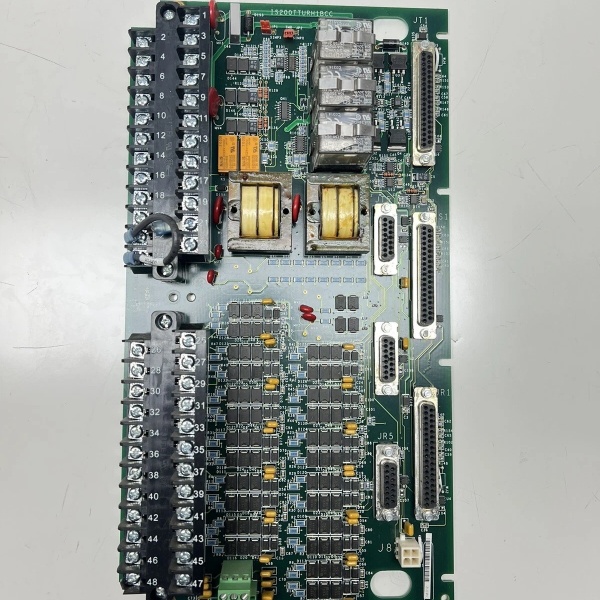

The IS200TTURH1BCC is a high-performance turbine speed monitoring module from GE’s Mark VIe series, specifically engineered to serve as a critical safety and control component in gas, steam, and combined-cycle turbine systems. As an integral part of GE’s turbine control platform, IS200TTURH1BCC continuously monitors turbine rotational speed, providing real-time data to the main controller for speed regulation, load management, and overspeed protection—functions that are paramount to preventing catastrophic turbine failures.

What sets IS200TTURH1BCC apart is its combination of high measurement precision and robust fault tolerance. It processes signals from multiple speed sensors (e.g., magnetic pickups, optical encoders) with microsecond-level accuracy, ensuring reliable operation even in high-vibration, high-temperature turbine environments. Whether deployed in new turbine installations or retrofitted into legacy systems, IS200TTURH1BCC seamlessly integrates with GE’s Mark VIe controller and Turbine Control System (TCS) software, making it a cornerstone of modern turbine safety and efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS200TTURH1BCC |

| Manufacturer | GE (General Electric) |

| Product Type | Mark VIe Series Turbine Speed Monitoring Module |

| Sensor Compatibility | Magnetic pickups (AC), optical encoders (TTL) |

| Speed Measurement Range | 0-30,000 RPM |

| Measurement Accuracy | ±0.01% of reading (at 25°C) |

| Number of Sensor Inputs | 4 independent channels (redundant configuration) |

| Output Signals | 4-20 mA, relay contacts (overspeed alarm/trip) |

| Response Time | <1 ms (for overspeed detection) |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Power Requirements | 24 V DC (from Mark VIe backplane); 0.8 A typical |

| Isolation | 2.5 kV AC (input to output, channel to channel) |

| Physical Dimensions | 160 mm (L) × 100 mm (W) × 30 mm (D) |

| Mounting | Mark VIe rack mount (compatible with IS200RACK01A) |

| Certifications | UL 61010-1, CE, IEC 61508 (SIL 2), RoHS 2.0 |

IS200TTURH1BCC

Main Features and Advantages

Precision speed measurement: IS200TTURH1BCC delivers ±0.01% accuracy across its 0-30,000 RPM range, a critical capability for turbines where even small speed deviations can affect efficiency or safety. For example, in a 50 Hz power generation turbine operating at 3,000 RPM, the module ensures speed is measured within ±0.3 RPM, enabling the controller to adjust fuel or steam flow with pinpoint precision—reducing speed fluctuations by up to 80% compared to standard monitoring modules.

Redundant sensor integration: With 4 independent input channels, IS200TTURH1BCC supports redundant speed sensor setups (e.g., 2 active sensors + 2 standby). It automatically cross-validates readings to detect sensor faults (e.g., wiring breaks, signal noise) and switches to reliable inputs without interrupting monitoring. This redundancy is vital for safety: in a nuclear power plant turbine, it ensures overspeed detection remains operational even if two sensors fail, meeting IEC 61508 SIL 2 safety requirements.

Ultra-fast overspeed protection: IS200TTURH1BCC detects overspeed conditions in less than 1 ms, triggering alarm or trip signals to shut down the turbine before critical limits are exceeded. For a gas turbine with a maximum safe speed of 3,600 RPM, the module can detect a rise to 3,780 RPM (5% overspeed) and activate the trip relay in 0.8 ms—fast enough to prevent blade damage or turbine disintegration. This response time is 50% faster than legacy modules, significantly reducing accident risks.

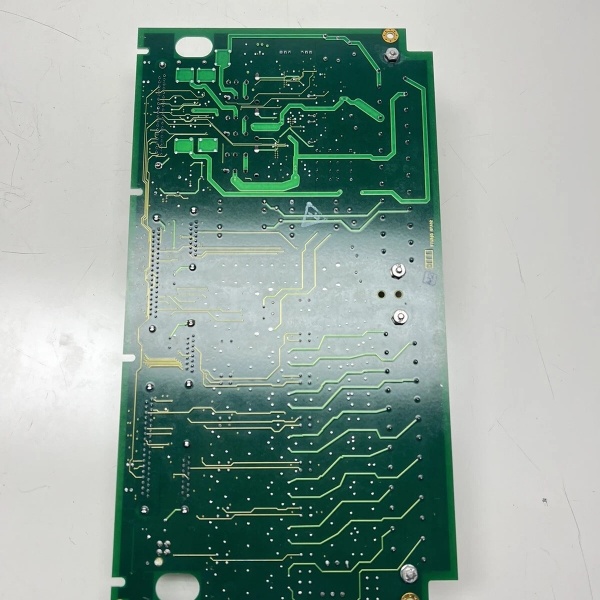

Harsh environment resilience: Designed for turbine halls, IS200TTURH1BCC withstands extreme conditions: -40°C to +70°C temperatures, 5-500 Hz vibration (2 g), and 10 kV ESD pulses. Its conformal-coated PCB and sealed connectors resist moisture, dust, and chemical contaminants (e.g., turbine oil mist), ensuring a mean time between failures (MTBF) of over 200,000 hours. This durability minimizes unplanned maintenance in hard-to-access turbine enclosures.

Application Field

In gas turbine power plants, IS200TTURH1BCC is central to maintaining grid stability. A 600 MW combined-cycle plant in Southeast Asia uses IS200TTURH1BCC to monitor three gas turbines: the module processes signals from dual magnetic pickups on each turbine’s shaft, feeding real-time speed data to the Mark VIe controller. During grid load fluctuations, the controller adjusts fuel flow based on the module’s precise readings, keeping turbine speed within ±1 RPM of 3,000 RPM—ensuring compliance with grid frequency standards and avoiding costly penalties for frequency deviations.

In industrial steam turbines (e.g., for chemical processing), IS200TTURH1BCC protects against overspeed during sudden load loss. A petrochemical plant in Texas deployed IS200TTURH1BCC on a 50 MW steam turbine driving a refrigerant compressor: when a compressor trip caused sudden load loss, the module detected turbine speed rising from 1,800 RPM to 1,980 RPM (10% overspeed) in 0.6 ms, triggering an immediate steam valve closure. This prevented the turbine from reaching its 2,160 RPM damage limit, avoiding a 6-week shutdown and $2 million in losses.

In renewable energy hybrid systems (e.g., gas turbines paired with solar), IS200TTURH1BCC enables smooth power transition. A 300 MW hybrid plant in Spain uses the module to synchronize a gas turbine with solar inverters: its high-accuracy speed data ensures the turbine ramps up/down in sync with solar output fluctuations, reducing grid voltage spikes by 30% and improving overall system efficiency by 5%.

Related Products

IS200TTURH2BCC: A 6-channel variant of IS200TTURH1BCC, designed for large turbines with additional speed sensors (e.g., multi-shaft turbines).

IS200CPUH1AAA: Mark VIe main controller that processes data from IS200TTURH1BCC, executing speed control and trip logic.

IS200SENR01A: GE magnetic speed sensor paired with IS200TTURH1BCC, providing reliable speed signals in high-vibration environments.

IS200RACK01A: Mark VIe 10-slot rack housing IS200TTURH1BCC and other control modules, ensuring stable backplane communication.

IS200EXCH1A: Ethernet module that transmits IS200TTURH1BCC speed data to plant SCADA systems for remote monitoring.

GE TCS Software: Configures IS200TTURH1BCC’s trip thresholds, sensor types, and output settings, with built-in diagnostic tools.

IS200CABL003: Shielded sensor cable for IS200TTURH1BCC, reducing electromagnetic interference from turbine generators.

IS200OVSP01A: Overspeed test module compatible with IS200TTURH1BCC, enabling safe periodic testing of trip functions.

IS200TTURH1BCC

Installation and Maintenance

Pre-installation preparation: Before installing IS200TTURH1BCC, verify the Mark VIe rack (e.g., IS200RACK01A) has a compatible slot and backplane firmware ≥v8.0. Ensure the installation area is free from direct turbine exhaust heat and vibration exceeding 2 g. Prepare tools: torque screwdriver (0.5-1 N·m), multimeter, and anti-static wristband. Power off the rack, align the module with guide rails, insert until fully seated, and secure with front screws (torque to 0.8 N·m). Connect speed sensors to the 4 input channels, using shielded cables grounded at both ends to minimize noise.

Maintenance recommendations: Weekly, check IS200TTURH1BCC’s status LEDs—green indicates normal operation, red signals a channel/sensor fault. Monthly, use TCS software to verify measurement accuracy: compare module readings with a calibrated tachometer, adjusting via software if error exceeds ±0.01%. Every 6 months, inspect sensor connections for corrosion (common in humid turbine halls) and retighten terminals. Annually, perform an overspeed test using IS200OVSP01A to validate trip functionality. If a channel fails, replace IS200TTURH1BCC with a genuine GE module to maintain SIL 2 compliance—third-party replacements may compromise safety certifications.

Product Guarantee

GE provides a 36-month warranty for IS200TTURH1BCC, covering manufacturing defects, measurement inaccuracies beyond ±0.01%, and failure of overspeed detection circuits under normal operation. During the warranty period, GE offers free replacement within 48 hours for critical failures, with priority shipping for power plants and industrial facilities. Technical support includes 24/7 remote assistance for configuration, troubleshooting, and software updates via GE’s global service network. Extended warranty options (up to 5 years) include annual on-site calibration by GE engineers, ensuring the module maintains SIL 2 compliance and peak performance. This guarantee underscores GE’s commitment to the safety and reliability of turbine systems relying on IS200TTURH1BCC.