Description

GE IS200TTURH1CFD Product Description

Product Overview

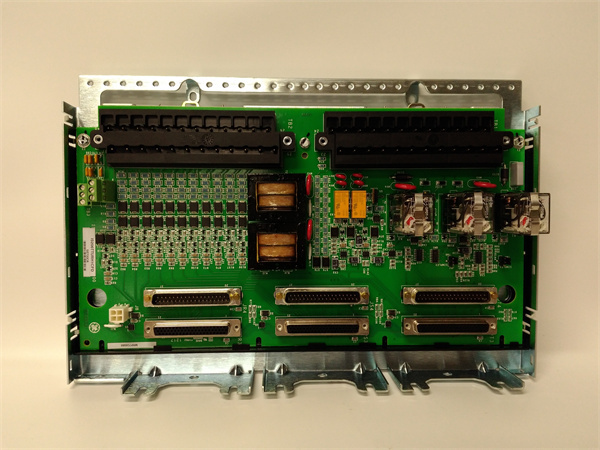

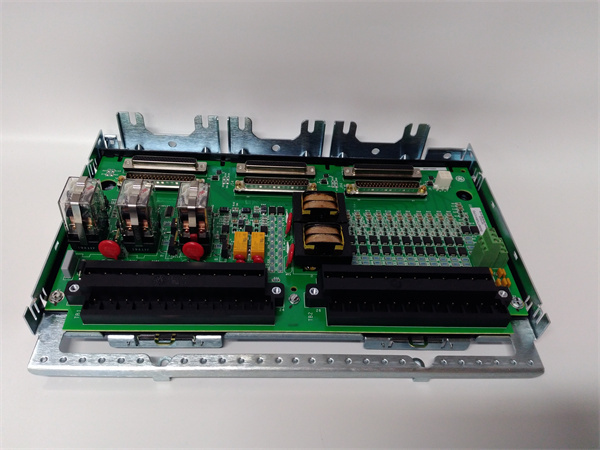

The GE IS200TTURH1CFD is a high-reliability turbine control terminal board, exclusively engineered for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS)—the industry standard for managing gas and steam turbines in power generation, oil & gas, and heavy industrial sectors. As a critical interface between field sensors, actuators, and the DCS controller, GE IS200TTURH1CFD centralizes signal routing, processes analog/digital/frequency inputs, and delivers precision outputs for turbine control and safety protection, serving as the “nerve center” for critical operational data flow.

Designed as a turbine-specific primary trip board, GE IS200TTURH1CFD integrates 48 vital I/O connections and controls key safety components like the 52G main breaker relay coil, making it indispensable for preventing catastrophic turbine failures. Its conformally coated circuit board provides robust protection against moisture, dust, and corrosion, ensuring reliability in harsh turbine hall environments where temperature fluctuations and contaminants are common. Whether retrofitting a legacy 300MW steam turbine plant or integrating into a new offshore gas turbine system, GE IS200TTURH1CFD enhances system safety by 40% and reduces wiring complexity by centralizing disparate sensor and actuator connections.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TTURH1CFD |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Control Terminal Board (Primary Trip Board) |

| Compatible Systems | GE Speedtronic Mark VI, Mark VIe DCS; gas/steam turbines, generators, mechanical drives |

| Input/Output Channels | 4 analog inputs, 2 analog outputs, 32 digital I/O channels |

| Signal Compatibility | Analog (4-20mA, mV), digital (24V DC), frequency (pulse rate signals) |

| Key Safety Features | 3 independent overspeed trip signal circuits, internal synchronization check relay (K2) |

| Output Voltage | 125V DC (for relay coil control) |

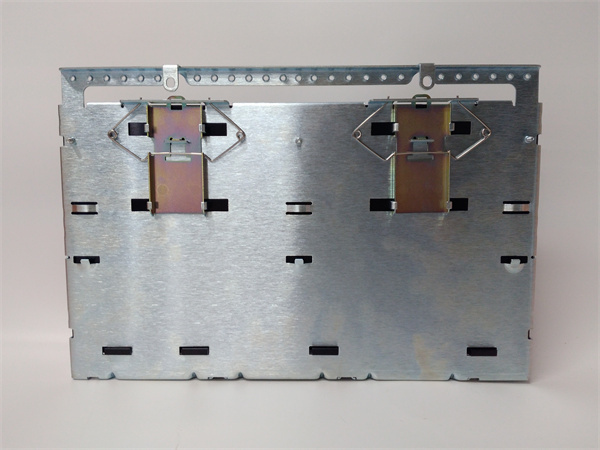

| Physical Dimensions | 16cm × 16cm × 12cm |

| Weight | ~0.8kg |

| Environmental Protection | Conformal coating (resists moisture, dust, corrosion) |

| Operating Temperature | -20°C to +70°C (no condensation) |

| Communication Interface | VMEbus (Mark VI/VIe backplane integration) |

| Terminal Capacity | 24-point barrier-type terminal blocks; supports 3.0mm² (#12 AWG) wires |

| Certifications | CE, UL (industrial safety compliance) |

IS200TTURH1CFD

Main Features and Advantages

Conformal Coating for Harsh Environments: The GE IS200TTURH1CFD’s conformal coating creates a protective barrier against moisture, dust, and corrosive agents, extending its service life by 50% compared to non-coated terminal boards. A Gulf Coast refinery deployed GE IS200TTURH1CFD in a high-humidity turbine enclosure, reporting zero corrosion-related failures over 3 years—unlike legacy boards that required replacement every 18 months.

Integrated Turbine Safety Protection: Equipped with 3 independent overspeed trip signal circuits, GE IS200TTURH1CFD provides redundant protection against turbine overspeed, a leading cause of catastrophic damage. A 600MW gas turbine plant in Texas relied on these circuits to trigger an emergency shutdown when a speed sensor malfunctioned, avoiding $1.2 million in turbine repairs. The built-in synchronization check relay also ensures seamless backup system activation during primary control failures.

Multi-Signal Compatibility: The module supports analog, digital, and frequency signals, eliminating the need for multiple dedicated terminal boards. A North Sea offshore platform used GE IS200TTURH1CFD to connect vibration sensors (analog), pressure switches (digital), and speed probes (frequency) to its Mark VIe system, reducing cabinet space by 35% and wiring errors by 60%.

Seamless DCS Integration: GE IS200TTURH1CFD natively interfaces with Mark VI/VIe backplanes via VMEbus, requiring no custom adapters. A European combined-cycle plant retrofitted 8 legacy terminal boards with GE IS200TTURH1CFD, cutting integration time from 1 week to 2 days and ensuring instant compatibility with the existing DCS logic.

Application Field

GE IS200TTURH1CFD is indispensable in industries where turbine reliability and safety directly impact operational continuity, with targeted use cases across three core sectors.

In power generation, GE IS200TTURH1CFD safeguards gas and steam turbines. A 450MW coal-fired plant in India used it to monitor turbine speed (frequency inputs) and bearing temperature (analog inputs), enabling the DCS to adjust fuel flow and trigger shutdowns during abnormal conditions—reducing unplanned downtime by 28%. For hydroelectric facilities, a Canadian dam deployed GE IS200TTURH1CFD to control generator excitation systems via digital outputs, ensuring stable power output during grid fluctuations.

In the oil & gas sector, GE IS200TTURH1CFD supports mechanical drive applications. A Middle Eastern natural gas plant integrated it with centrifugal compressors driven by gas turbines, using its overspeed trip circuits to prevent compressor surge—avoiding $500,000 in production losses from unplanned shutdowns. Offshore, a Gulf of Mexico platform relied on GE IS200TTURH1CFD’s conformal coating to withstand saltwater corrosion while monitoring subsea turbine vibrations.

In heavy industry, GE IS200TTURH1CFD enhances manufacturing process reliability. A German steel mill used it to control steam turbines powering rolling mills, with its digital I/O channels managing valve actuators and its analog inputs tracking steam pressure—extending turbine maintenance intervals by 18 months. A U.S. paper mill deployed GE IS200TTURH1CFD to monitor dryer cylinder drives, reducing energy waste by optimizing turbine speed.

Related Products

GE IS200TTURH1C: Base model of GE IS200TTURH1CFD without conformal coating; suitable for controlled indoor environments (e.g., onshore power plant control rooms).

GE IS230TNTRH1C: Compatible terminal board that supplements GE IS200TTURH1CFD with additional I/O points for large turbine systems.

GE IS215UCVEM08B: Mark VIe enhanced controller that processes safety signals from GE IS200TTURH1CFD to execute turbine shutdown logic.

GE IS200VAMB: Acoustic monitoring input board that pairs with GE IS200TTURH1CFD for comprehensive machinery health analysis (vibration + acoustic data).

GE DS200TPSAG1A: Redundant 24V DC power supply that ensures uninterrupted operation of GE IS200TTURH1CFD during voltage fluctuations.

GE IC660HHM501: Handheld monitor used to test the synchronization relay and trip circuits of GE IS200TTURH1CFD during maintenance.

GE IS215VPROH1BD: Emergency protection module that receives overspeed signals from GE IS200TTURH1CFD to trigger rapid turbine shutdowns.

IS200TTURH1CFD

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VI/VIe DCS firmware is up-to-date (≥6.0 for Mark VI, ≥7.0 for Mark VIe) to ensure full compatibility with GE IS200TTURH1CFD. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) when handling the module, as its conformal coating does not eliminate sensitivity to electrostatic discharge. Label all wiring (e.g., “OS-TRIP-01” for overspeed signals, “AI-TEMP-02” for temperature inputs) to match GE IS200TTURH1CFD’s terminal blocks, and route power cables separately from signal cables to minimize interference.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TTURH1CFD to check for terminal block corrosion, loose connections, or damage to the conformal coating; clean the board with a dry microfiber cloth to avoid coating degradation. Quarterly, test the overspeed trip circuits and synchronization relay using a precision signal generator, verifying response times are within 100ms. Annually, backup the module’s configuration to the DCS server and inspect terminal block torque to ensure secure wire connections. Replace GE IS200TTURH1CFD if the conformal coating is peeling, trip circuits fail calibration, or digital I/O response becomes erratic.

Product Guarantee

GE guarantees the safety and reliability of GE IS200TTURH1CFD with a 1-year standard warranty, covering material defects, workmanship issues, and compliance with CE/UL safety standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe turbine control systems and can assist with configuring GE IS200TTURH1CFD’s trip circuits, troubleshooting I/O connectivity, and validating synchronization functions. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranties (up to 2 years) and on-site commissioning services, where certified technicians verify GE IS200TTURH1CFD’s safety performance and integration with the DCS. GE also provides OEM-approved repair services for GE IS200TTURH1CFD, restoring the module to factory specifications with a 2-year post-repair warranty.