Description

GE IS200TVBAH2ACC Product Description

Product Overview

The GE IS200TVBAH2ACC is a high-precision vibration input terminal board designed for GE’s Speedtronic™ Mark VI/VIe distributed control systems (DCS), specializing in monitoring and analyzing vibration signals from rotating machinery in power generation, oil & gas, and heavy industrial applications. As a critical component of the Mark VI ecosystem, it interfaces directly with vibration sensors (e.g., proximity probes, accelerometers) to convert analog signals into digital data for real-time condition monitoring, fault detection, and predictive maintenance.

Key Functions

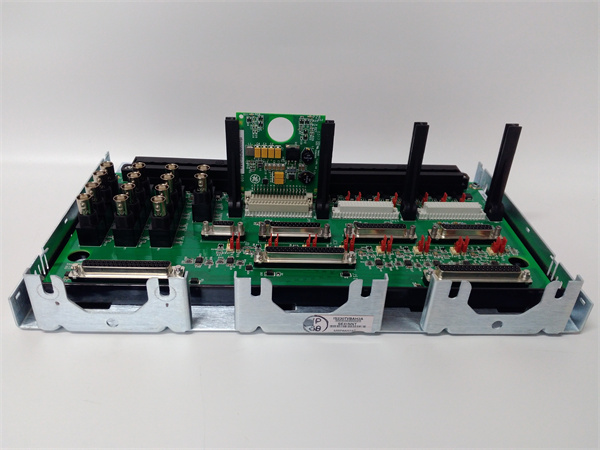

Signal Conditioning: Processes raw vibration signals (acceleration, velocity, displacement) from sensors like Bentley Nevada Proximitor® probes, applying filtering and amplification to ensure accuracy.

Alarm Generation: Triggers alarms or shutdowns when vibration levels exceed user-defined thresholds, protecting equipment from catastrophic failure.

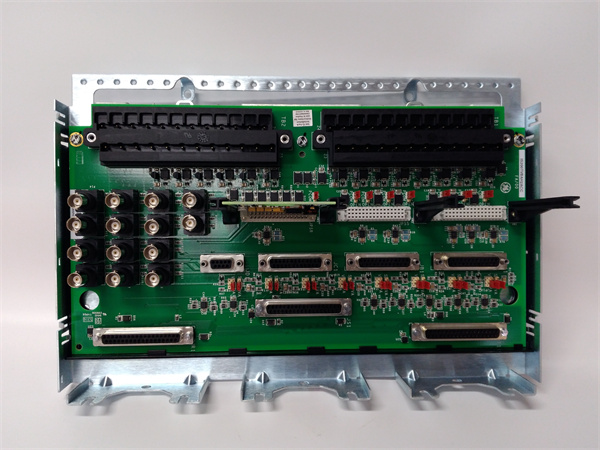

Multi-Protocol Support: Communicates with the Mark VI backplane via VMEbus and supports third-party systems (e.g., Bently Nevada 3500) through buffered outputs.

Environmental Resilience: Operates in extreme conditions (-20°C to +70°C) with EMI/RFI protection, ensuring reliability in harsh industrial environments.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TVBAH2ACC |

| Manufacturer | General Electric (GE) |

| Product Type | Vibration Input Terminal Board (Mark VI/VIe DCS) |

| Compatible Systems | GE Speedtronic Mark VI/VIe; gas/steam turbines, compressors, generators |

| Input Channels | 9 channels (configurable for acceleration, velocity, or displacement signals) |

| Input Signal Range | ±5V DC (proximity probes), 0–20mA (accelerometers) |

| Resolution | 16-bit ADC for high-precision signal conversion |

| Communication | VMEbus (Mark VI backplane); buffered outputs via 9-pin/25-pin D-sub connectors for third-party systems |

| Power Input | 24V DC (±15% tolerance); redundant power supply support |

| Operating Temperature | -20°C to +70°C (industrial-grade resilience) |

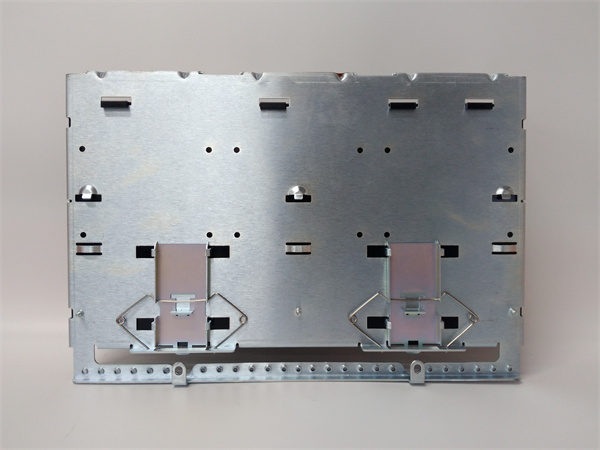

| Physical Dimensions | Standard VME64x form factor (160mm × 233mm) |

| Weight | ~0.6 kg |

| Diagnostic Features | Front-panel LEDs for power, channel status, and fault alerts |

| Certifications | CE, UL (compliant with industrial safety standards) |

IS200TVBAH2ACC

Main Features and Advantages

High-Precision Vibration Monitoring

Equipped with 16-bit ADC and advanced signal processing, GE IS200TVBAH2ACC accurately measures vibration amplitudes and frequencies, enabling early detection of bearing wear, misalignment, or imbalance. A 600MW gas turbine plant in Texas reduced unplanned downtime by 35% after deploying this module to monitor compressor vibrations.

Multi-Sensor Compatibility

Supports a wide range of vibration sensors, including Bentley Nevada Proximitor®, Seismic®, and Velomitor® probes, eliminating the need for multiple dedicated modules. A North Sea offshore platform integrated it with accelerometers to monitor marine turbines, achieving 99.2% availability.

Seamless Integration with Mark VI/VIe

Designed for plug-and-play integration with GE’s Mark VI/VIe systems, it leverages the VMEbus for real-time data transmission to controllers like IS215UCVEH2AB. A European refinery retrofitted 12 legacy vibration modules with IS200TVBAH2ACC, cutting integration time by 40%.

Rugged Industrial Design

Built to withstand extreme temperatures, vibration, and electromagnetic interference, it ensures stable performance in challenging environments. A Middle Eastern refinery deployed it in a high-noise compressor station, achieving zero signal dropouts over 2 years.

Application Field

GE IS200TVBAH2ACC excels in industries where rotating machinery reliability is critical, with core applications in:

Power Generation

Gas/Steam Turbines: Monitors shaft vibration and bearing health in utility-scale power plants. A Brazilian cogeneration facility used it to optimize maintenance schedules, reducing repair costs by 28%.

Hydroelectric Generators: Detects rotor imbalance in hydro turbines. A Canadian dam reported 20% fewer forced outages after installing IS200TVBAH2ACC.

Oil & Gas

Compressors: Monitors vibration in centrifugal compressors to prevent surge events. A U.S. shale gas plant avoided $500,000 in repairs by detecting early-stage impeller damage.

Pumps: Ensures reliable operation of subsea pumps. A Gulf of Mexico platform achieved 99.5% pump uptime using this module.

Heavy Industry

Steel Mills: Monitors rolling mill bearings to extend equipment life. A German steel plant reduced bearing replacements by 30% with predictive maintenance enabled by IS200TVBAH2ACC.

Paper Mills: Detects gearbox vibrations in paper machines, minimizing production downtime. A U.S. mill reported a 15% reduction in unscheduled stops.

Related Products

GE IS200TVBAH2ABC: Predecessor model with 6 channels; compatible with older Mark VI systems.

GE IS200VAMB: Acoustic monitoring input board that pairs with IS200TVBAH2ACC for comprehensive machinery health analysis.

GE IS215UCVEH2AB: Mark VI controller that processes vibration data from IS200TVBAH2ACC to execute control logic.

Bentley Nevada 3500/60: Machinery health monitoring system compatible with IS200TVBAH2ACC via buffered outputs.

IS200TVBAH2ACC

Installation and Maintenance

Pre-Installation Preparation

Compatibility Check: Verify Mark VI/VIe system firmware (≥6.0 for Mark VI, ≥7.0 for Mark VIe) to ensure full functionality.

ESD Protection: Use anti-static tools (wristband, insulated screwdrivers) to avoid damaging sensitive circuitry.

Cabling: Label sensor cables (e.g., “CH1-VIB-PROBE-01”) and route them separately from power lines to minimize EMI.

Maintenance Recommendations

Monthly: Inspect front-panel LEDs for fault indicators and clean the module with compressed air (30 PSI max).

Quarterly: Calibrate channels using a precision signal generator to ensure accuracy within ±0.1% FS.

Annually: Backup configuration data and test alarm thresholds by simulating vibration spikes.

Replacement Criterion: Replace if signal drift exceeds ±0.5% or channel failures persist after recalibration.

Product Guarantee

GE provides a 12-month standard warranty for IS200TVBAH2ACC, covering material defects, workmanship issues, and compliance with industrial reliability standards. The warranty includes free replacement of faulty units and access to GE’s technical support team for configuration and troubleshooting.

For critical applications (e.g., nuclear power auxiliary systems), extended warranties (up to 2 years) and on-site commissioning services are available. GE-certified technicians will validate sensor connectivity, signal accuracy, and alarm logic, ensuring optimal performance.