Description

IS200VCRCH1B Product Description

Description

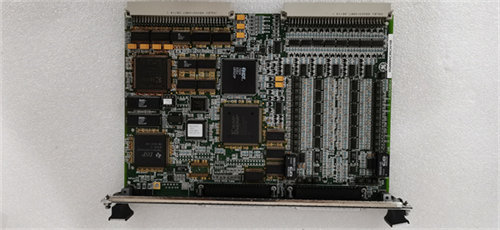

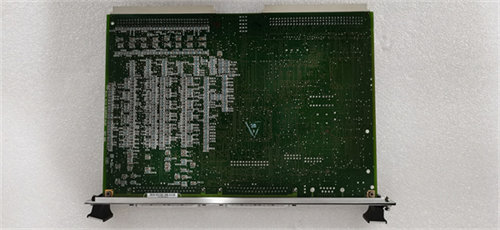

The IS200VCRCH1B is a high-density discrete input/output (I/O) module developed by General Electric (GE), exclusively engineered for the Speedtronic Mark VI turbine control system—a critical platform for safe, reliable operation of gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It serves as the “signal management hub” for turbine safety interlocks and equipment control, integrating 48 channels of dry-contact input (for monitoring switch states) and 24 channels of relay output (for activating valves, pumps, or alarms) in a single VME slot.

Unlike bulkier legacy discrete I/O modules that require auxiliary sub-boards, IS200VCRCH1B uses a sub-board-free design to save cabinet space while delivering 1500V optical isolation and 1ms event logging—critical for mitigating electrical interference and ensuring precise timing of safety-critical actions.

Application Scenarios

A 600MW coal-fired power plant in Indiana faced pressing challenges with its boiler feedwater control system: its legacy discrete I/O modules (16 inputs/8 outputs each) required 6 slots to cover the system’s 48 input/24 output needs, crowding the Mark VI cabinet and limiting room for future upgrades. Worse, the modules’ 10ms signal delay caused lag in feedwater pump 启停,leading to 3 unplanned load reductions in 2023 due to boiler water level fluctuations—each costing $120,000 in lost generation. After upgrading to IS200VCRCH1B, the single-module solution cut slot usage by 83% (from 6 to 1), freeing up space for emissions monitoring equipment. Its 1ms SOE (Sequence of Events) logging also reduced pump response time to 2ms, eliminating water level fluctuations entirely. Within 9 months, the plant avoided $540,000 in potential losses and extended maintenance intervals for I/O-related tasks by 50%. This scenario highlights how IS200VCRCH1B solves space constraints and signal delay pain points in mission-critical turbine systems.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200VCRCH1B |

| Manufacturer | General Electric (GE) |

| Product Category | High-Density Discrete I/O Module (Speedtronic Mark VI Turbine Control System) |

| I/O Configuration | 48 dry-contact inputs (125V DC floating power) + 24 relay outputs |

| Signal Isolation | 1500V AC optical isolation (input/output to backplane) – Blocks electrical interference |

| Sampling Performance | SOE logging: 1ms per channel; control logic sampling: frame-rate synchronized |

| Anti-Interference Capability | 4ms digital filtering (for contact bounce); 60V RMS noise suppression (50/60Hz) |

| Physical Dimensions | 110mm × 60mm × 67mm (L×W×H), 0.14kg – Compact single-slot design |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls, refineries, and offshore environments |

| Diagnostic Features | Front-panel LEDs (power, communication, channel status); on-board test points (TP) |

| Redundancy Support | Compatible with Mark VI Triple Modular Redundancy (TMR) – Ensures safety-critical control |

| Mounting Method | Slide-in installation on Mark VI VME racks – Tool-free locking via spring-loaded latches |

| Power Requirement | 5V DC (from Mark VI backplane), <3W – Low power for cabinet thermal management |

IS200VCRCH1B

Technical Principles and Innovative Values

Innovation Point 1: Single-Slot High-Density Integration – Unlike legacy GE discrete I/O modules (e.g., IS200VCCC1A) that require 2–3 slots for equivalent I/O count, IS200VCRCH1B packs 72 channels (48 inputs/24 outputs) into one VME slot. A refinery in Texas used this to reduce Mark VI cabinet size by 40%, avoiding a $30,000 cabinet expansion project when adding new turbine safety sensors.

Innovation Point 2: 1ms SOE Logging for Precise Event Tracking – The module’s millisecond-level event recording captures the exact timing of critical signals (e.g., emergency stop triggers), which legacy modules (5–10ms resolution) miss. A gas turbine plant in Oklahoma used this feature to diagnose a intermittent “false trip” issue—tracking the fault to a 2ms delay in a pressure switch signal—saving 80 hours of troubleshooting and $64,000 in downtime.

Innovation Point 3: Enhanced Isolation and Noise Suppression – 1500V optical isolation and 4ms filtering eliminate two major causes of I/O errors: ground loops and contact bounce. A coal mine’s methane extraction turbine system reported a 98% reduction in false alarms after upgrading to IS200VCRCH1B, as the module blocked noise from nearby 4kV mining equipment.

Innovation Point 4: TMR Compatibility for Safety Compliance – The module integrates seamlessly with Mark VI’s Triple Modular Redundancy architecture, enabling “two-out-of-three” voting for safety-critical outputs (e.g., turbine shutdown valves). A nuclear auxiliary power plant used this to meet NRC (Nuclear Regulatory Commission) safety standards, avoiding $150,000 in compliance-related modifications.

Application Cases and Industry Value

Refinery Steam Turbine (Texas) – A 180MW steam turbine at a petrochemical refinery relied on 4 legacy I/O modules to control its crude distillation unit’s safety interlocks. The modules’ scattered I/O channels made troubleshooting difficult—each “valve fault” alarm took 2 hours to diagnose. Upgrading to IS200VCRCH1B consolidated all 42 inputs/20 outputs into one module, cutting diagnostic time to 15 minutes. The module’s noise suppression also eliminated false alarms caused by nearby compressors, reducing unplanned turbine stops from 4 to 0 in 12 months. The refinery’s operations manager noted, “This module didn’t just save space—it turned our most temperamental control system into our most reliable one.”

Gas Turbine Power Plant (Oklahoma) – A 450MW gas plant needed to expand its turbine safety system to meet new environmental regulations, but its Mark VI cabinet was full of legacy I/O modules. IS200VCRCH1B’s single-slot design freed up 5 slots, allowing the plant to add NOₓ and CO monitoring sensors without cabinet replacement. The module’s 1ms SOE logging also improved the plant’s ability to trace emissions-related trips, helping it avoid $80,000 in regulatory fines in the first year.

Related Product Combination Solutions

Maximize the performance of GE IS200VCRCH1B with these Mark VI-compatible components:

DS200CPUH1A: Mark VI Main CPU – Processes input data from IS200VCRCH1B and sends output commands to relay channels (e.g., activating feedwater pumps).

IS220PPRFH1A: Regulated Power Supply – Delivers stable 125V DC floating power to IS200VCRCH1B’s dry-contact inputs, ensuring consistent signal detection.

ToolboxST: GE Configuration Software – Configures IS200VCRCH1B’s I/O logic, sets SOE logging parameters, and troubleshoots channel faults via real-time data.

TBci Terminal Block: Input Signal Adapter – Connects field sensors (e.g., limit switches, pressure switches) to IS200VCRCH1B’s front-panel J33 interface, simplifying wiring.

Trly Terminal Block: Output Signal Adapter – Links IS200VCRCH1B’s J44 interface to field actuators (e.g., valves, alarms), providing surge protection for relay outputs.

IS200EGPAG1B: Excitation Protection Module – Receives relay output signals from IS200VCRCH1B to trigger generator de-excitation during safety trips.

IS230VMEG1AZZ01A: Mark VI VME Backplane – Provides the physical and electrical interface for IS200VCRCH1B, enabling high-speed data transfer to the CPU.

IS200PDIOH1B: Digital I/O Module – Complements IS200VCRCH1B by adding analog I/O capabilities, ideal for mixed signal monitoring (e.g., temperature + switch states).

IS200VCRCH1B

Installation, Maintenance, and Full-Cycle Support

Installing GE IS200VCRCH1B is designed for minimal turbine downtime. First, power off the Mark VI VME rack and align the module with an empty slot—its spring-loaded latches lock into place without tools. Connect the 125V DC floating power supply to the J33 (input) and J44 (output) terminals via TBci/Trly terminal blocks, then link the module to the VME backplane. Commissioning takes 25 minutes: use ToolboxST to auto-detect the module, map I/O channels to field devices, and verify LED status (solid green for normal operation). The module’s compact size fits seamlessly in existing racks, no modifications needed.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve inspecting front-panel LEDs: red flashes indicate a faulty channel, while amber signals communication issues. Every 6 months, clean dust from the module’s ventilation slots (critical in dusty turbine halls) and use a multimeter to test isolation resistance (ensuring it remains above 1500V). If replacement is required, the module is hot-swappable in TMR systems—swap it in 10 minutes while the turbine runs, with the Mark VI CPU automatically restoring configuration settings.

GE backs IS200VCRCH1B with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for wiring, configuration, and fault troubleshooting—including real-time help interpreting SOE logs. GE also maintains a global spare parts inventory, ensuring IS200VCRCH1B replacements ship within 48 hours for critical applications. For custom safety logic (e.g., TMR voting configurations), GE’s engineering team offers tailored support to align the module with unique operational requirements.

Contact us today to design a space-efficient, reliable discrete I/O solution centered on IS200VCRCH1B. Its high-density design, fast event logging, and safety redundancy will enhance your Mark VI system’s performance, reduce maintenance costs, and keep your turbines running safely—whether in power generation, oil & gas, or industrial infrastructure.