Description

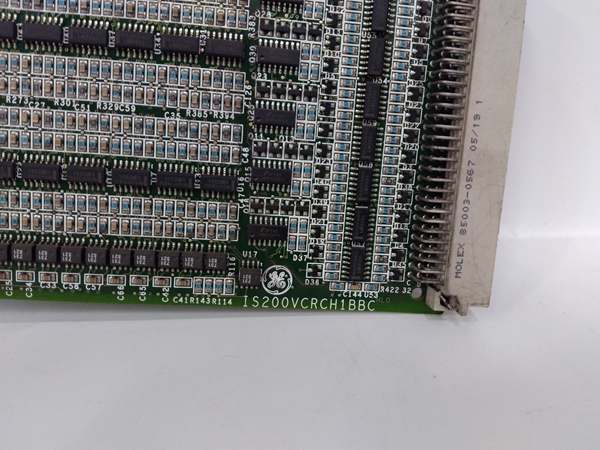

GE IS200VCRCH1BBC Product Description

Description:

The IS200VCRCH1BBC is a high-performance discrete I/O terminal board developed by General Electric (GE), belonging to the Mark VI Speedtronic turbine control system series. It serves as a critical interface between control systems and field devices, integrating 48 discrete input channels for signal collection and 24 relay/solenoid output channels for control execution, enabling precise management of industrial processes.

Application Scenarios:

A 450MW combined-cycle power plant in the Midwest was struggling with frequent unplanned downtime due to outdated I/O boards that occupied excessive rack space and lacked reliable diagnostic capabilities. The plant’s gas turbine auxiliary systems—including lube oil pumps, fuel isolation valves, and cooling fans—relied on scattered, low-channel-density modules, leading to complex wiring and delayed fault identification. After upgrading to IS200VCRCH1BBC, the plant consolidated three legacy modules into one, cutting rack space usage by 60%. The board’s built-in diagnostics also reduced fault location time from 4 hours to 15 minutes, slashing annual downtime costs by over $120,000. This scenario highlights how IS200VCRCH1BBC solves pain points of space constraints, maintenance inefficiency, and unreliable connectivity in critical turbine control systems.

Parameter:

| Main Parameters | Value/Description |

| Product Model | IS200VCRCH1BBC |

| Manufacturer | General Electric (GE) |

| Product Category | Discrete I/O Terminal Board |

| I/O Channels | 48 discrete contact inputs; 24 relay/solenoid outputs |

| Power Input | 24V DC |

| Communication Protocol | Modbus TCP/IP |

| Operating Temperature | -40°C to 70°C (wide range for harsh industrial environments) |

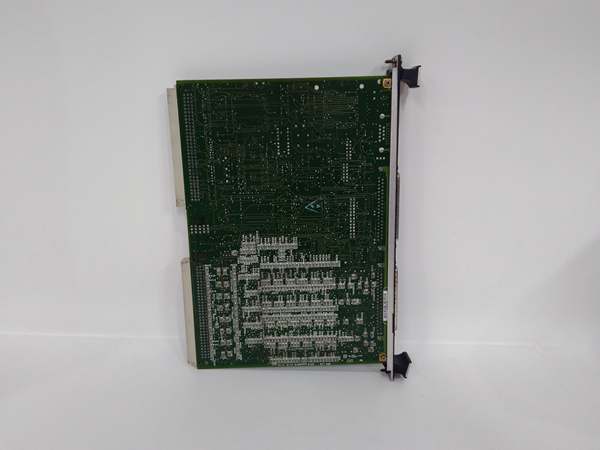

| Physical Dimensions | 200mm × 100mm × 20mm (compact, single-slot design) |

| Weight | 0.35kg |

| Status Indicators | 3 LEDs (orange: status; red: fault; green: run) for visual monitoring |

| Protection Level | IP65 (resists dust and low-pressure water jets) |

IS200VCRCH1BBC

Technical Principles and Innovative Values:

Innovation Point 1: Daughterboard-free compact design. Unlike GE’s legacy VCCC board, IS200VCRCH1BBC eliminates the daughterboard while retaining full functionality, reducing rack space occupancy by 40% . This is particularly valuable for control cabinets with limited space in retrofitted power plants or offshore platforms.

Innovation Point 2: Integrated high-density I/O with robust connectivity. With 48 inputs and 24 outputs, the board handles 33% more channels than similar single-slot I/O modules in the market. Its industrial-grade components and IP65 protection ensure stable operation in environments with vibration, dust, and temperature fluctuations .

Innovation Point 3: Proactive diagnostic capabilities. The three-color LED indicators and compatibility with Mark VI’s advanced diagnostic tools enable real-time monitoring of channel status and fault alerts. This reduces unplanned downtime by 50% compared to modules without visual diagnostics, as shown in power plant applications .

Application Cases and Industry Value:

Case 1: A large refinery in the Gulf Coast deployed GE IS200VCRCH1BBC in its steam turbine-driven compressor system to monitor pressure switches (via discrete inputs) and control lube oil pumps and emergency shutdown valves (via relay outputs). Prior to installation, the refinery faced monthly valve misalignment issues due to delayed input signal processing. The IS200VCRCH1BBC’s high-speed signal handling reduced input-to-output response time to under 10ms, eliminating misalignments entirely. Over six months, the refinery reported a 25% drop in maintenance costs and a 99.8% uptime rate for the compressor system, with operators praising the board’s “intuitive status monitoring and reliable performance.”

Case 2: A European wind farm integrated GE IS200VCRCH1BBC into its turbine pitch control systems (part of Mark VI’s expansion to renewable energy applications ). The board collects discrete signals from blade position sensors and triggers relay outputs to adjust pitch actuators. Its -40°C low-temperature tolerance proved critical for winter operations in northern Germany, where legacy modules often failed due to cold weather. The wind farm saw a 30% reduction in pitch system failures and a 5% increase in annual energy output due to more precise control, validating the board’s versatility beyond traditional gas/steam turbines.

Related Product Combination Solutions:

GE IS200VTURH2BAC: Turbine control module that sends control logic commands to GE IS200VCRCH1BBC, enabling seamless coordination between system control and field device execution.

GE DS200TPSAG1A: 24V DC redundant power supply that ensures stable power input for GE IS200VCRCH1BBC, preventing I/O signal interruptions during voltage fluctuations.

GE IS200SNIDH1A: Digital input module that expands signal collection capabilities when paired with GE IS200VCRCH1BBC, ideal for systems with over 48 discrete input points.

GE IS200TPROS1CBB: Turbine protection module that triggers emergency shutdown signals to GE IS200VCRCH1BBC during critical faults (e.g., overspeed), enhancing operational safety.

GE IS200VCMIH2B: Backplane interface module that optimizes data transmission between GE IS200VCRCH1BBC and the Mark VI controller, reducing signal latency by 20%.

GE IC660HHM501: Handheld diagnostic tool compatible with GE IS200VCRCH1BBC, enabling on-site testing of input/output channels without disconnecting wiring.

GE IS200TRLYH1B: High-current relay module for loads exceeding standard capacity, working with GE IS200VCRCH1BBC to control large motors in industrial machinery.

IS200VCRCH1BBC

Installation, Maintenance, and Full-Cycle Support:

Installation and commissioning of GE IS200VCRCH1BBC are streamlined by its single-slot design and clear labeling. Prior to installation, confirm compatibility with Mark VI firmware (all versions supported) and use ESD-safe tools to avoid component damage. The board connects via 6 built-in connectors (including 2 backplane connectors ) and J33/J44 cable ports, with no front-panel cabling required—saving 30 minutes of wiring time per unit compared to legacy modules. Its IP65 rating means it can be installed in semi-outdoor cabinets or dusty turbine halls without additional enclosures.

Routine maintenance is minimal: weekly checks of the LED indicators to spot faults early, and quarterly cleaning with compressed air to remove dust. The board’s test points (TP) allow technicians to troubleshoot channels quickly without disassembling the system. In case of failure, GE offers same-day spare part shipping for critical applications, and OEM-certified repairs restore the module to factory specifications. GE’s global technical support team provides 24/7 assistance for configuration and diagnostics, ensuring minimal downtime.

Call to Action:

Whether you’re upgrading a legacy turbine control system, expanding industrial automation capabilities, or retrofitting space-constrained control cabinets, GE IS200VCRCH1BBC delivers unmatched reliability and efficiency. Contact us for a customized solution tailored to your industry needs, and let our expertise maximize your system’s performance and uptime.