Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200VGENH1B |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Mid-Range Voltage Signal Generation & Isolation Module (Mark VIe Speedtronic Turbine Control System) |

| Core function | Generates stable precision voltage signals (for sensor calibration/debugging); provides isolation between Mark VIe system and external test equipment |

| Output signal type | Voltage: 0–5 V DC, 0–10 V DC, ±5 V DC, ±10 V DC (software-selectable per channel) |

| Output channel quantity | 4 independent isolated channels; supports simultaneous multi-range signal output |

| Signal accuracy | ±0.05% of full scale (at 25°C); ±0.1% over operating temperature range |

| Signal stability | ≤50 ppm/°C (temperature coefficient); ≤0.01%/24 hours (long-term drift) |

| Isolation rating | Output-to-input: 3.0 kV RMS; Channel-to-channel: 2.0 kV RMS; Output-to-backplane: 5.0 kV RMS |

| Communication interface | Mark VIe backplane (1 Gbps bus); front-panel Ethernet (Modbus TCP) for remote signal configuration |

| Operating temperature range | -40 °C to +75 °C (-40 °F to 167 °F); no derating up to 70 °C |

| Power requirements | 24 V DC (±15%); Max current draw: 0.6 A; built-in voltage reference (10 V DC, ±0.01% stability) |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC Immunity: Level 4); UL 61010-1; IEC 61508 SIL 1 |

| MTBF (Mean Time Between Failures) | 4,000,000 hours (per Telcordia SR-332, 40 °C ambient) |

| Physical dimensions | 16.5 cm (H) × 10.2 cm (W) × 5.0 cm (D) (6.5 in × 4.0 in × 1.97 in) |

| Weight | 0.59 kg (1.30 lbs) |

| Compatibility | Mark VIe Series B/C/D controllers; IS200CABPG1B/IS200CABPG2B backplanes; pairs with IS200BPIAG1A (analog input) / IS200ACLEH1A (signal conditioner) |

| Calibration support | NIST-traceable internal reference; supports external calibration via ToolboxST software |

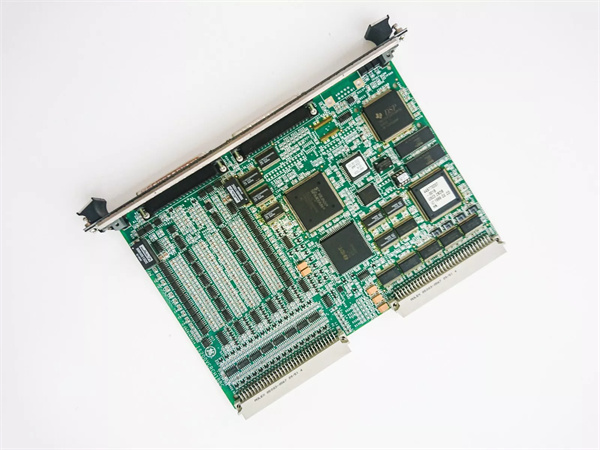

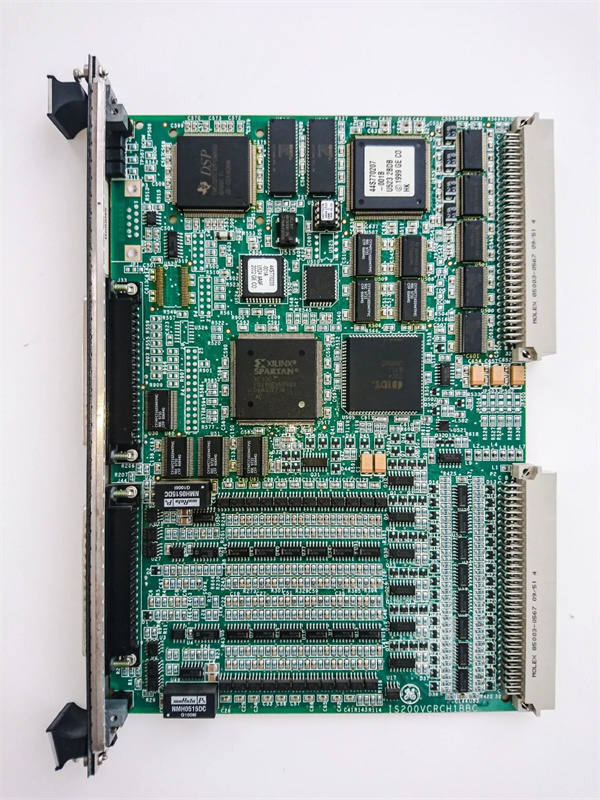

IS200VGENH1B

Product Introduction

The IS200VGENH1B is a mid-range voltage signal generation & isolation module engineered by GE for Mark VIe Speedtronic control systems, designed to be the “precision signal source” for turbine system maintenance and debugging. Unlike basic external signal generators (which lack Mark VIe integration) or high-end calibration modules (with excessive safety certifications), IS200VGENH1B balances functionality and cost: it generates stable voltage signals (0–10 V DC/±10 V DC) for calibrating analog input modules like IS200BPIAG1A, provides electrical isolation to protect the Mark VIe backplane from external test equipment, and supports remote configuration via Ethernet—all while avoiding the premium of safety-grade units.

In GE’s turbine ecosystem, IS200VGENH1B acts as a critical “calibration bridge” between the Mark VIe system and field sensors. For example, during quarterly maintenance of an IS200BPIAG1A analog input module, IS200VGENH1B generates a 0–10 V DC reference signal (corresponding to 0–100 °C for a PT100B RTD) with ±0.05% accuracy. This signal is fed to IS200BPIAG1A to verify its digitization accuracy—any deviation beyond ±0.1% triggers a calibration via ToolboxST, ensuring the module maintains precise measurement of auxiliary steam temperature.

A practical application highlights its value: a 600 MW combined-cycle plant deployed 3 IS200VGENH1B modules to calibrate 48 IS200BPIAG1A units across two gas turbines. Previously, the plant used portable external generators, which required manual wiring to each module and lacked isolation—leading to 2–3 backplane transient faults annually (each costing \(15,000 in downtime). With **IS200VGENH1B**, calibration time per module dropped from 30 minutes to 5 minutes, isolation eliminated transient faults, and remote configuration reduced on-site labor by 60%—saving \)45,000 annually.

Core Advantages and Technical Highlights

High-Precision Signal Generation for Reliable Calibration: IS200VGENH1B’s ±0.05% accuracy and ≤50 ppm/°C temperature coefficient ensure consistent reference signals for module calibration. A nuclear auxiliary power plant used the module to calibrate IS200BPIAG1A units monitoring lube oil temperature: the generated ±5 V DC signal (corresponding to 0–100 °C) maintained ≤0.01% drift over 24 hours, enabling IS200BPIAG1A to retain ±0.1 °C measurement accuracy. This eliminated monthly re-calibrations with external equipment, saving $20,000 in annual calibration costs.

Multi-Channel Isolation for System Protection: With 3.0 kV output-to-input isolation and 2.0 kV channel-to-channel isolation, IS200VGENH1B protects the Mark VIe backplane from voltage transients from external test tools. A wind farm maintenance team accidentally connected a 240 V AC tool to a non-isolated generator, causing a backplane fault that shut down 3 turbines ($75,000 in lost production). After switching to IS200VGENH1B, a similar incident was blocked by the module’s isolation, preventing downtime and equipment damage.

Remote Configuration via Ethernet for Efficiency: The front-panel Ethernet port (Modbus TCP) lets technicians configure signals from a central control room, avoiding on-site cabinet access. A chemical plant with 10 distributed turbine enclosures used this feature to calibrate 80 IS200BPIAG1A modules from a single location—reducing travel time between enclosures by 80% and cutting maintenance shifts from 3 days to 1 day. The module’s integration with ToolboxST also enables automated calibration sequences, further streamlining workflows.

Built-In Voltage Reference for Long-Term Stability: IS200VGENH1B includes a 10 V DC internal reference with ±0.01% stability, eliminating the need for external precision references. A pulp mill with a 300 MW process turbine previously used external references that required annual replacement (\(5,000 per unit). The module’s built-in reference retained calibration for 3 years, saving \)15,000 and reducing maintenance complexity.

Typical Application Scenarios

In a GE 9HA.01 gas turbine plant (750 MW), 4 IS200VGENH1B modules are used for monthly calibration of 64 IS200BPIAG1A units monitoring auxiliary parameters: 24 combustion cooling air temperature sensors, 16 fuel gas pressure transducers, 24 lube oil level sensors. The modules are mounted in IS200CABPG2B backplanes, powered by IS200CPFXG1A supplies, and connected to IS200BPIAG1A via shielded cables. During calibration, IS200VGENH1B generates 0–10 V DC/±5 V DC signals (matching sensor output ranges) and transmits data to the control room via Ethernet. Technicians verify IS200BPIAG1A’s digitization accuracy in real time—any deviation >±0.1% triggers an automated calibration via ToolboxST. This process ensures IS200BPIAG1A maintains precise measurements, preventing fuel waste from incorrect pressure readings ($30,000 annual savings).

At a remote diesel-fired power plant (100 MW) with limited on-site staff, 2 IS200VGENH1B modules support both calibration and troubleshooting. During a recent IS200BPIAG1A fault (incorrect temperature readings), technicians remotely configured IS200VGENH1B to generate a 0–5 V DC signal (simulating a PT100B RTD). The signal confirmed IS200BPIAG1A was faulty (digitization error of 0.5%), allowing the team to ship a replacement module before a critical maintenance window. This proactive troubleshooting avoided a 4-hour unplanned shutdown ($40,000 in lost production).

Related Model Recommendations

IS200BPIAG1A: GE’s high-precision analog input module. Primary calibration target for IS200VGENH1B—the generated voltage signals verify IS200BPIAG1A’s digitization accuracy.

IS200ACLEH1A: GE’s mid-range signal conditioner. Pairs with IS200VGENH1B to test signal preprocessing—IS200VGENH1B generates low-level signals (±1 V DC) for IS200ACLEH1A to amplify/filter, validating conditioner performance.

IS200CABPG2B: GE’s redundant backplane. Mounts IS200VGENH1B and provides stable communication with the Mark VIe CPU—critical for remote calibration workflows.

IS200CPFXG1A: GE’s enhanced power supply. Delivers noise-free 24 V DC to IS200VGENH1B—ensures the module’s internal reference maintains ±0.01% stability.

IS200EACFG2A: GE’s configuration module. Stores IS200VGENH1B’s signal settings (range, accuracy) for plug-and-play replacement—reduces reconfiguration time after module swap.

GE Fluke 754 Documenting Process Calibrator: External calibration tool. Used to validate IS200VGENH1B’s internal reference annually—ensures NIST-traceability.

IS200JGNDG1A: GE’s grounding module. Enhances IS200VGENH1B’s isolation by providing a low-impedance ground path—reduces ground loops in high-noise environments.

IS200TFBAH1A: GE’s Mark VIe CPU module. Triggers automated calibration sequences via IS200VGENH1B—integrates calibration results into the plant’s maintenance management system.

IS200VGENH1B

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Power off the IS200CABPG2B backplane and use ESD-safe tools. Verify compatibility with Mark VIe Series B/C/D controllers and ensure the power supply provides 24 V DC ±15%. For wiring:

Connect output channels to IS200BPIAG1A/IS200ACLEH1A input terminals using 22 AWG shielded twisted-pair cables—ground shields at both ends to reduce noise.

Connect the Ethernet port to the plant’s network for remote access; assign a static IP address compatible with the Mark VIe system.

Torque terminal screws to 0.6–0.8 N·m and label channels with signal range (e.g., “Channel 1 – 0–10 V DC (Temp Sensor Cal)”).

Commissioning Steps

Use GE’s ToolboxST software to configure IS200VGENH1B after installation:

Set output signal range per channel (e.g., Channel 1: 0–10 V DC, Channel 2: ±5 V DC) and enable isolation for each output.

Calibrate the module’s internal reference using a NIST-traceable tool (e.g., Fluke 754): inject a 10 V DC reference signal, adjust IS200VGENH1B’s output to match within ±0.01%.

Test remote configuration via Ethernet: Send a signal command (e.g., 5 V DC on Channel 1) from the control room, verify output with a multimeter—ensure response time <100 ms.

Validate isolation: Apply a 3.0 kV RMS test voltage between output and input terminals for 1 minute—confirm no current leakage (>100 MΩ resistance).

Maintenance Suggestions

Monthly: Check signal stability by generating a 5 V DC signal and measuring drift with a precision multimeter—drift should not exceed ±0.01%/24 hours.

Quarterly: Verify isolation resistance using a megohmmeter—output-to-input resistance should remain >100 MΩ.

Annually: Calibrate the internal reference with a NIST-traceable tool (e.g., Fluke 8508A)—adjust via ToolboxST if deviation exceeds ±0.05%.

Biennially: Clean backplane connectors with compressed air (30 PSI max) and inspect Ethernet wiring for damage—critical for remote calibration workflows.

If signal accuracy drifts beyond ±0.1%: First re-calibrate the internal reference; replace the module only if re-calibration fails (use GE-approved units to maintain isolation standards).

Service and Guarantee Commitment

IS200VGENH1B comes with a 3-year standard warranty from GE, covering defects in the internal reference, isolation circuits, and communication components. For in-warranty failures (e.g., signal drift >±0.1%, isolation breakdown, Ethernet communication loss), GE ships a replacement within 24 hours from regional hubs (North America, Europe, Asia) and provides free remote re-calibration support.

GE offers 24/7 global technical support for IS200VGENH1B: Certified Mark VIe engineers assist with signal configuration, isolation testing, and automated calibration setup via phone, email, or remote desktop. Customers receive access to the module’s calibration guides, EMC test reports, and compatibility matrices for Mark VIe I/O modules.

For critical calibration applications (e.g., 9HA/9F gas turbine auxiliary systems), GE offers a 5-year extended warranty including annual on-site calibration and internal reference validation. These services ensure the module maintains ±0.05% accuracy and complies with IEC 61010-1 safety standards, supporting reliable turbine maintenance workflows.

If you need to streamline analog input module calibration or protect your Mark VIe system from external test equipment transients, contact us for a customized IS200VGENH1B integration plan—our team will optimize signal ranges, wiring, and remote workflows to maximize maintenance efficiency and system safety.