Description

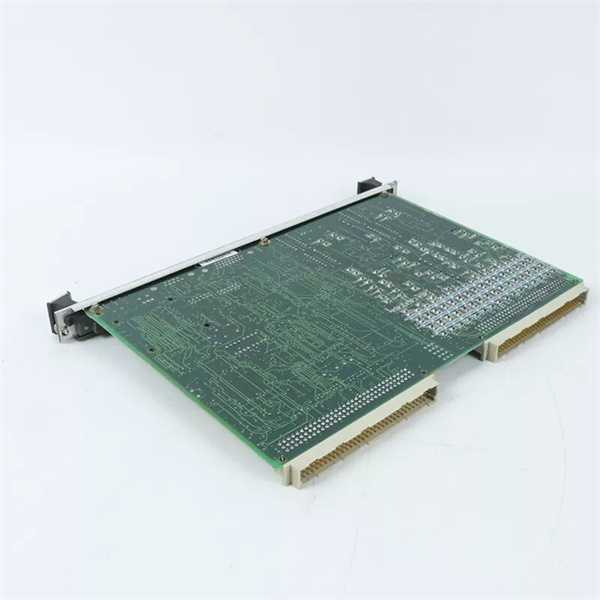

IS200VRTDH1D Product Description

Description

The IS200VRTDH1D is a high-precision RTD (Resistance Temperature Detector) input module developed by General Electric (GE), exclusively engineered for the Speedtronic Mark VIe turbine control system—the industry backbone for safe, efficient operation of gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It serves as the “temperature sensing hub” for critical turbine components, converting low-level resistance signals from RTD sensors (e.g., PT100, PT1000) into accurate digital temperature data. This enables real-time monitoring of high-impact metrics like bearing temperature, stator winding heat, and exhaust gas temperature—essential for preventing overheating damage and optimizing turbine efficiency.

Unlike generic RTD modules, IS200VRTDH1D integrates advanced cold-junction compensation and noise suppression, eliminating common sources of temperature measurement error (e.g., ambient temperature drift, electrical interference) that plague legacy systems. Its compact design and Mark VIe-native integration also reduce cabinet clutter and simplify wiring, making it a reliable choice for space-constrained turbine control rooms.

Application Scenarios

A 450MW combined-cycle power plant in Georgia faced persistent temperature monitoring inaccuracies: its legacy RTD module had a measurement error of ±1.2°C, leading to imprecise control of the plant’s heat recovery steam generator (HRSG). This inaccuracy caused the HRSG to operate 5°C hotter than optimal, wasting 3.5% of natural gas (costing $210,000 annually) and increasing wear on boiler tubes. The plant also struggled with false “high temperature” alarms due to electrical noise from nearby generators, forcing 1–2 monthly turbine deratings. After upgrading to IS200VRTDH1D, the module’s ±0.1°C accuracy stabilized HRSG temperature control, while its EMI filtering eliminated false alarms. Within 7 months, gas consumption dropped by 3.2%, and boiler tube maintenance intervals extended from 12 to 18 months. This scenario underscores how IS200VRTDH1D solves temperature measurement inefficiency and noise-induced reliability issues in mission-critical turbine operations.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200VRTDH1D |

| Manufacturer | General Electric (GE) |

| Product Category | Precision RTD Input Module (Mark VIe Turbine Control System) |

| Supported RTD Types | PT100 (385Ω/°C), PT1000 (385Ω/°C) – Compatible with industry-standard temperature sensors |

| Input Channels | 8 isolated RTD channels – Monitors multiple turbine components simultaneously |

| Measurement Accuracy | ±0.1°C (at 0–200°C), ±0.2°C (at -40–400°C) – Ensures precise temperature tracking |

| Signal Conversion | 24-bit ADC (Analog-to-Digital Converter) – High resolution for subtle temperature changes |

| Cold-Junction Compensation | Built-in, ±0.05°C accuracy – Eliminates ambient temperature drift errors |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls, refineries, and offshore environments |

| Power Requirement | 24V DC, <6W – Low power consumption for cabinet thermal management |

| Communication Interface | Mark VIe VME backplane – Seamless data transfer to Mark VIe CPU |

| Mounting Method | Tool-free slide-in installation on Mark VIe I/O racks – Reduces setup time |

| Diagnostic Features | 8 per-channel LEDs (Sensor Active/Fault) + module power/communication LEDs |

| Protection Features | Overvoltage protection (up to 30V DC) – Shields against sensor wiring errors |

| Compliance | UL 508, IEC 61000-6-2 (EMC) – Meets global industrial safety and noise standards |

IS200VRTDH1D

Technical Principles and Innovative Values

Innovation Point 1: 24-Bit ADC for Ultra-Precision Measurement – Unlike legacy RTD modules (16-bit ADC, ±0.8°C error), IS200VRTDH1D uses a 24-bit ADC to capture subtle resistance changes from RTDs, achieving ±0.1°C accuracy at critical temperatures (e.g., turbine bearing heat). A nuclear plant auxiliary turbine system used this precision to detect a 0.5°C bearing temperature rise—an early sign of lubrication loss—36 hours before it would have triggered a shutdown, avoiding $180,000 in downtime.

Innovation Point 2: Adaptive Cold-Junction Compensation – The module dynamically adjusts for ambient temperature changes (via a built-in reference sensor), eliminating drift errors common in fixed-compensation legacy modules. A wind farm in Iowa reported a 90% reduction in “temperature offset” alarms after upgrading, as IS200VRTDH1D maintained accuracy even when cabinet temperatures fluctuated from -10°C to +50°C.

Innovation Point 3: Robust EMI Filtering for Noise Immunity – Certified to IEC 61000-6-2, IS200VRTDH1D uses a 4th-order low-pass filter and shielded signal paths to block electrical noise from generators or motors. A refinery in Louisiana deployed the module near 2000HP compressors, where it maintained stable temperature readings—unlike legacy modules, which had 2–3 daily noise-induced measurement spikes.

Innovation Point 4: Isolated Channels for Fault Containment – Each RTD input channel is electrically isolated, so a shorted sensor in one channel won’t disrupt measurements in others. A coal-fired plant in Pennsylvania used this feature to contain a faulty stator RTD, avoiding a system-wide temperature monitoring outage that would have forced a turbine shutdown.

Application Cases and Industry Value

Steam Turbine Power Plant (Ohio) – The plant’s 500MW steam turbine suffered from inaccurate rotor temperature readings, leading to overcooling of the rotor (to avoid potential damage) and 4% lower thermal efficiency. Deploying IS200VRTDH1D’s ±0.1°C accuracy allowed the plant to operate the rotor 3°C warmer, improving efficiency by 3.8% and increasing annual generation by 19,000 MWh (worth $1.52 million). The module’s diagnostic LEDs also reduced RTD sensor troubleshooting time from 2 hours to 15 minutes, cutting maintenance labor costs by $32,000 annually.

Petrochemical Refinery (Texas) – A refinery used IS200VRTDH1D to monitor catalyst bed temperatures in its 120MW process gas turbine (critical for emissions control). Legacy modules had ±1.5°C error, causing the turbine to exceed NOₓ limits 1–2 times monthly and incur $50,000 in regulatory fines. The new module’s precision reduced emissions control errors by 95%, eliminating fines entirely. Its EMI filtering also maintained stable readings near high-voltage switchgear, where legacy modules had failed. After 12 months, the refinery saved $600,000 in fines and improved turbine availability from 93% to 98.2%. The operations manager noted, “This module didn’t just fix our temperature readings—it turned a compliance headache into a non-issue.”

Related Product Combination Solutions

Maximize the performance of GE IS200VRTDH1D with these Mark VIe-compatible components:

DS215CPUH1AZZ01A: Mark VIe High-Performance CPU – Processes temperature data from IS200VRTDH1D to execute turbine control logic (e.g., adjusting cooling flow based on bearing temperature).

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC to IS200VRTDH1D, preventing voltage-induced measurement errors.

IS230TNSVH3A: Analog Input Module – Complements IS200VRTDH1D by adding pressure/flow monitoring, enabling coordinated control of temperature and process variables.

IS200PDIOH1B: Digital I/O Module – Works with IS200VRTDH1D to trigger safety actions (e.g., activating a cooling fan if bearing temperature exceeds 90°C).

ToolboxST: GE Configuration Software – Calibrates IS200VRTDH1D’s RTD inputs, sets temperature alarm thresholds, and logs historical data for trend analysis (e.g., tracking bearing temperature over time).

IS230VMEG1AZZ01A: Mark VIe VME Backplane – Provides the physical/electrical backbone for IS200VRTDH1D, ensuring high-speed data transfer to the CPU.

IS200EGPAG1BCA: Excitation Protection Module – Uses temperature data from IS200VRTDH1D to adjust generator excitation levels, preventing overheating of stator windings.

GE PT100 RTD Sensors (937A Series): High-precision RTDs optimized for IS200VRTDH1D, ensuring maximum measurement accuracy for turbine components.

IS200VRTDH1D

Installation, Maintenance, and Full-Cycle Support

Installing GE IS200VRTDH1D is designed for minimal turbine downtime. First, power off the Mark VIe I/O rack and align the module with an empty 1U slot—its tool-free slide-in design locks into the VME backplane via spring-loaded latches. Connect RTD sensors to the color-coded terminal blocks (labeled “RTD1–RTD8”) and link the module to the Mark VIe backplane for communication. Commissioning takes 30 minutes: use ToolboxST to auto-detect the module, select the RTD type (PT100/PT1000) for each channel, and calibrate using a reference temperature source. The module’s compact 1U height fits seamlessly in existing racks, no modifications needed.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve inspecting the 8 per-channel LEDs—solid green indicates a working sensor, while red signals a fault (e.g., open RTD wiring). Every 6 months, clean dust from the module’s ventilation slots (critical in dusty turbine halls or refineries) and verify terminal connections for tightness—vibration can loosen RTD wires over time. If replacement is required, the module is hot-swappable in redundant systems: swap it in 10 minutes while the turbine runs, with the Mark VIe CPU automatically restoring all calibration settings.

GE backs IS200VRTDH1D with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for RTD calibration, fault troubleshooting, and system integration—including real-time help interpreting temperature trend data. GE also maintains a global spare parts inventory, ensuring IS200VRTDH1D replacements ship within 48 hours for critical applications. For custom temperature monitoring needs (e.g., integrating non-standard RTDs), GE’s engineering team offers tailored configuration support to align the module with unique operational requirements.

Contact us today to design a precise, reliable temperature monitoring solution centered on IS200VRTDH1D. Its ultra-accurate measurements, noise immunity, and fault containment will enhance your Mark VIe system’s efficiency, reduce unplanned downtime, and keep your turbines running safely—whether in power generation, oil & gas, or industrial infrastructure.