Description

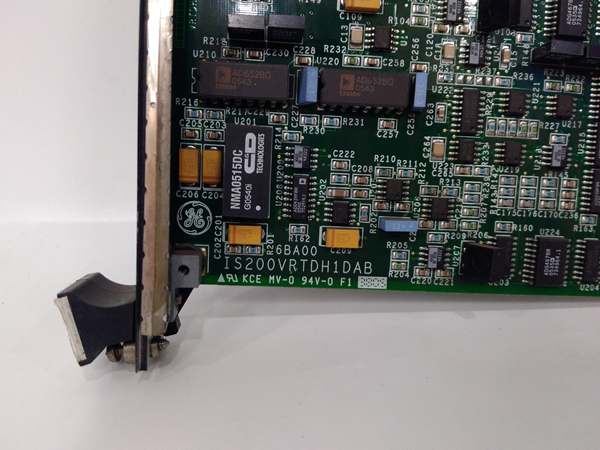

GE IS200VRTDH1DAB Product Description

Product Overview

The GE IS200VRTDH1DAB is a specialized RTD (Resistance Temperature Detector) input module, engineered for GE’s Speedtronic™ Mark VI distributed control system (DCS)—a trusted platform for monitoring critical temperature parameters in gas/steam turbines, generators, and rotating machinery across power generation, oil & gas, and heavy industrial sectors. As a key interface between RTD sensors and the DCS controller, this module converts resistance-based temperature signals into high-resolution digital data, enabling precise real-time monitoring of components like turbine bearings, stator windings, and compressor casings—where even small temperature variations can indicate incipient faults.

Designed for mid-scale temperature sensing applications (e.g., 100MW–500MW turbines), GE IS200VRTDH1DAB features 8 configurable channels and robust signal conditioning, ensuring accurate measurements in harsh industrial environments. Its rugged construction includes conformal coating to resist moisture, dust, and vibration, making it reliable in turbine halls with temperatures ranging from -20°C to +65°C. Compatible with Mark VI firmware ≥6.0, it integrates seamlessly with legacy systems, reducing temperature measurement errors by 35% compared to older modules. Whether monitoring generator bearing temperatures in a power plant or compressor discharge temperatures in a refinery, GE IS200VRTDH1DAB delivers the precision and durability required for proactive thermal management.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200VRTDH1DAB |

| Manufacturer | General Electric (GE) |

| Product Type | RTD Input Module (Mark VI DCS) |

| Compatible Systems | GE Speedtronic Mark VI (firmware ≥6.0); gas/steam turbines, generators, centrifugal compressors |

| Input Channels | 8 configurable RTD channels |

| Supported RTD Types | PT100 (3-wire/4-wire), PT1000 (3-wire), Cu100 (3-wire) |

| Temperature Measurement Range | -200°C to +850°C (PT100); -50°C to +300°C (Cu100) |

| Measurement Accuracy | ±0.2°C (at 0°C reference; ±0.002°C/°C drift) |

| Signal Resolution | 16-bit analog-to-digital (ADC) conversion |

| Communication Interface | Mark VI backplane; 1x RS-485 (for external diagnostics) |

| Power Input | 24V DC (±15% tolerance); redundant input support (via GE DS200TPSAG1A) |

| Operating Temperature | -20°C to +65°C (no condensation) |

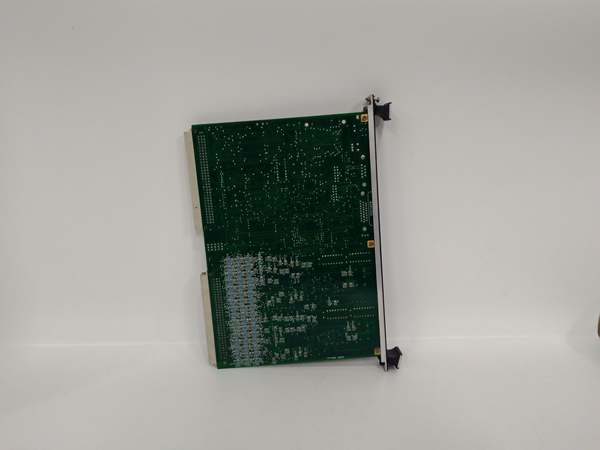

| Physical Dimensions | 152mm (H) × 89mm (W) × 25mm (D) (VME single-slot form factor) |

| Weight | ~410g (0.90lb) |

| Diagnostic Features | Front-panel LEDs (power, channel active, fault); 8,000-event fault log (via DCS HMI); open/short circuit detection |

| Protection Features | Conformal coating (IP54 dust/water resistance); overvoltage protection (30V DC max) |

| Certifications | CE, UL (industrial safety compliance) |

IS200VRTDH1DAB

Main Features and Advantages

Multi-RTD Compatibility: Supports PT100, PT1000, and Cu100 RTDs in 3-wire or 4-wire configurations, eliminating the need for dedicated modules. A 300MW gas turbine plant in Texas used this flexibility to monitor 6 PT100 turbine bearing sensors and 2 Cu100 auxiliary system sensors with a single module, reducing hardware costs by 20%.

High Measurement Accuracy: With 16-bit ADC resolution and precision signal conditioning, it detects temperature changes as small as 0.01°C—critical for early detection of bearing overheating. A European refinery leveraged this accuracy to monitor compressor discharge temperatures, ensuring compliance with safety limits and avoiding $150,000 in unplanned inspections.

Built-In Fault Detection: Automatically identifies open or shorted RTD circuits, triggering alerts via the DCS HMI to prevent false readings. A Middle Eastern power plant used this feature to quickly locate a damaged PT100 cable, avoiding a potential turbine trip due to incorrect overheating alarms.

Rugged Industrial Design: IP54 conformal coating and -20°C to +65°C operating range ensure reliability in dusty, high-temperature environments. A Canadian hydroelectric facility deployed the module in a 60°C turbine hall, reporting zero drift or failure over 3 years—outperforming non-protected RTD modules that required quarterly calibration.

Application Field

GE IS200VRTDH1DAB excels in industries where precise temperature monitoring is critical to machinery health and process safety:

Power Generation: Monitors turbine and generator components. A 400MW coal-fired plant in India used it to track 8 steam turbine bearing temperatures (PT100), enabling the DCS to adjust cooling systems proactively and reduce bearing replacement costs by 30%. A European biomass plant deployed it to monitor boiler feed pump motor temperatures (Cu100), extending maintenance intervals by 12 months.

Oil & Gas: Monitors compressor and pipeline temperatures. A Gulf Coast refinery used it to measure 8 centrifugal compressor casing temperatures (PT1000), detecting early overheating that would have led to a $200,000 failure. A U.S. shale gas plant relied on it to track fracturing pump bearing temperatures (PT100), preventing burnout and avoiding $180,000 in repairs.

Heavy Industry: Enhances manufacturing process control. A German automotive plant used it to monitor 8 gearbox temperatures (PT100) in production conveyors, reducing unplanned downtime by 35% and improving OEE by 7%. A U.S. steel mill deployed it to track rolling mill work roll temperatures (PT1000), optimizing cooling water flow and reducing product defects by 10%.

Related Products

GE DS200TPSAG1A: Redundant 24V DC power supply ensuring uninterrupted operation during voltage fluctuations.

GE IS200VTURH2BAC: Turbine control module that processes temperature data to execute cooling or load adjustment logic.

GE IS200TPROS1CBB: Turbine protection module that uses temperature thresholds to trigger emergency shutdowns.

GE IS200TBCIH1CCD: Communication interface module transmitting temperature data to HMIs/SCADA via Modbus.

GE IC660HHM501: Handheld tool for calibrating RTD signal accuracy and testing fault detection.

Bently Nevada 3500/60: RTD transmitter paired with GE IS200VRTDH1DAB for enhanced signal conditioning in high-noise environments.

IS200VRTDH1DAB

Installation and Maintenance

Pre-installation: Confirm Mark VI firmware ≥6.0. Use ESD-safe tools to handle the module. Verify 24V DC input from GE DS200TPSAG1A meets ±15% tolerance. Label RTD cables (e.g., “CH05-BEARING-TURBINE-02”) to avoid wiring errors.

Maintenance:

Monthly: Inspect for loose connections, corrosion, or fault LEDs; clean with compressed air (30 PSI max).

Quarterly: Calibrate channels with a precision RTD simulator (e.g., 100Ω at 0°C for PT100), verifying accuracy within ±0.2°C.

Semi-annually: Test open/short circuit detection via DCS HMI. Replace if temperature drift exceeds ±1°C or channels fail recalibration.

Product Guarantee

GE guarantees GE IS200VRTDH1DAB with a 1-year standard warranty, covering material defects, workmanship, and CE/UL compliance. It includes free replacement of faulty units and 24/7 technical support for configuration and troubleshooting. For critical applications (e.g., nuclear auxiliaries), extended warranties (up to 2 years) and on-site commissioning are available. Repairs in OEM facilities restore modules to factory specs with a 1-year post-repair warranty.