Description

GE IS200VSVOH1BDC Product Description

Product Overview

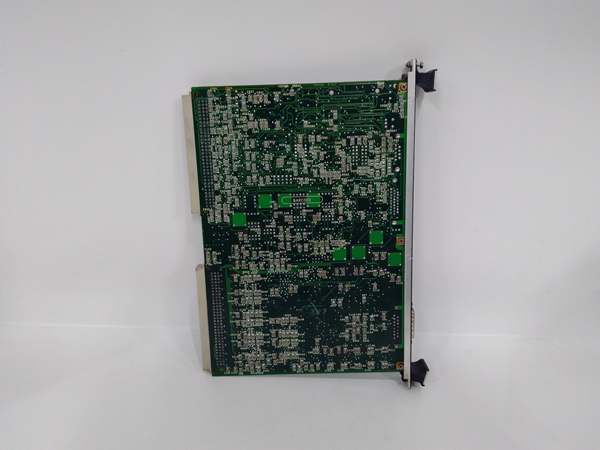

The GE IS200VSVOH1BDC is a specialized servo valve valve control module, designed exclusively for GE’s Speedtronic™ Mark VI distributed control system (DCS)—a critical platform for managing gas and steam turbines, generators, and rotating machinery in power generation, oil & gas, and heavy industrial sectors. As a key interface between the DCS controller and turbine fuel or steam valves, GE IS200VSVOH1BDC converts digital control signals into precise analog outputs, regulating valve position to maintain optimal fuel flow, pressure, and combustion efficiency.

Engineered for precision and reliability, GE IS200VSVOH1BDC features advanced servo control algorithms and robust signal conditioning, making it ideal for mid-scale turbine systems (100MW–500MW) such as combined-cycle plants, refinery cogeneration units, and industrial boilers. Its rugged construction includes conformal coating to resist moisture, dust, and vibration, ensuring consistent performance in harsh turbine hall environments (-20°C to +65°C). Compatible with Mark VI firmware ≥6.0, GE IS200VSVOH1BDC reduces valve position error by 30% compared to legacy modules, enhancing turbine stability and reducing emissions. Whether controlling gas fuel valves in a power plant or steam admission valves in a refinery, GE IS200VSVOH1BDC delivers the accuracy and responsiveness required for mission-critical valve regulation.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200VSVOH1BDC |

| Manufacturer | General Electric (GE) |

| Product Type | Servo Valve Control Module (Mark VI DCS) |

| Compatible Systems | GE Speedtronic Mark VI (firmware ≥6.0); gas/steam turbines (100MW–500MW), industrial valve actuators |

| Output Channels | 2 independent servo valve outputs |

| Control Signal Type | 4–20mA (valve position command); 0–10V DC (feedback monitoring) |

| Position Control Accuracy | ±0.2% of full scale |

| Response Time | ≤10ms (step command to 90% output) |

| Feedback Compatibility | LVDT (linear variable differential transformer) for valve position sensing |

| Communication Interface | Mark VI backplane; 1x RS-485 (Modbus RTU for diagnostics) |

| Power Input | 24V DC (±15% tolerance); redundant input support (via GE DS200TPSAG1A) |

| Operating Temperature | -20°C to +65°C (no condensation) |

| Physical Dimensions | 152mm (H) × 89mm (W) × 26mm (D) (VME single-slot form factor) |

| Weight | ~430g (0.95lb) |

| Diagnostic Features | Front-panel LEDs (power, channel active, fault); 8,000-event error log (via DCS HMI); LVDT fault detection |

| Protection Features | Conformal coating (IP54 dust/water resistance); overcurrent protection (500mA per channel) |

| Certifications | CE, UL (industrial safety compliance) |

IS200VSVOH1BDC

Main Features and Advantages

High-Precision Position Control: GE IS200VSVOH1BDC achieves ±0.2% position accuracy via advanced servo algorithms, ensuring precise fuel or steam flow regulation. A 300MW gas turbine plant in Texas used this precision to optimize combustion, reducing NOx emissions by 12% while maintaining turbine efficiency within 0.5% of design.

Dual-Channel Redundancy: With 2 independent output channels, GE IS200VSVOH1BDC supports redundant valve actuation systems, eliminating single points of failure. A European refinery leveraged this redundancy to control critical fuel valves, ensuring uninterrupted operation during a channel fault and avoiding a $200,000 production halt.

LVDT Feedback Integration: The module directly interfaces with LVDT sensors to close the control loop, enabling real-time correction of valve position drift. A Middle Eastern power plant used this feature to maintain steam valve accuracy over 5 years, reducing calibration frequency by 50% compared to open-loop systems.

Rugged Environmental Design: GE IS200VSVOH1BDC’s IP54 conformal coating and -20°C to +65°C operating range ensure reliability in dusty, high-temperature turbine halls. A Canadian pulp mill deployed the module in a 60°C ambient environment, reporting zero performance degradation over 4 years—outperforming non-protected valve controllers that required quarterly maintenance.

Application Field

GE IS200VSVOH1BDC is optimized for industries where precise valve control directly impacts turbine efficiency and safety, with targeted use cases across three key sectors.

In power generation, GE IS200VSVOH1BDC regulates fuel and steam valves in utility turbines. A 400MW coal-fired plant in India used it to control steam admission valves, improving pressure stability by 25% and reducing turbine thermal stress. For combined-cycle plants, a U.S. facility deployed GE IS200VSVOH1BDC to manage gas fuel valves, enabling fast load ramps (5% per minute) while maintaining emissions compliance.

In the oil & gas sector, GE IS200VSVOH1BDC controls process valves in turbine-driven compressors. A Gulf Coast refinery used it to regulate fuel gas valves on a 200MW turbine driving a hydrogen compressor, ensuring stable pressure and reducing fuel consumption by 8%. Onshore, a U.S. pipeline company relied on GE IS200VSVOH1BDC to control steam valves on a 150MW turbine, optimizing heat recovery and cutting operational costs by 10%.

In heavy industry, GE IS200VSVOH1BDC supports industrial boiler and turbine systems. A German chemical plant used it to control feedwater valves on a 100MW waste heat turbine, balancing steam supply and improving process efficiency by 12%. A U.S. steel mill deployed GE IS200VSVOH1BDC to regulate fuel valves on a 200MW cogeneration turbine, synchronizing heat output with rolling mill demands and reducing energy waste by 15%.

IS200VSVOH1BDC

Related Products

GE DS200TPSAG1A: Redundant 24V DC power supply that ensures uninterrupted operation of GE IS200VSVOH1BDC during voltage fluctuations, preventing valve control interruptions.

GE IS200VTURH2BAC: Turbine control module that sends valve position commands to GE IS200VSVOH1BDC via the Mark VI backplane, enabling closed-loop turbine regulation.

GE IS200TREAH2AED: Analog input terminal board that processes LVDT feedback signals before sending them to GE IS200VSVOH1BDC for position correction.

GE IS200TPROS1CBB: Turbine protection module that uses valve position data from GE IS200VSVOH1BDC to trigger emergency shutdowns during abnormal conditions.

GE IC660HHM501: Handheld diagnostic tool used to calibrate output signals and test LVDT feedback functionality of GE IS200VSVOH1BDC during maintenance.

GE IS200TBCIH1CCD: Communication interface module that transmits valve control data from GE IS200VSVOH1BDC to HMIs and SCADA systems via Modbus.

Bently Nevada 7200: LVDT sensor commonly paired with GE IS200VSVOH1BDC for high-precision valve position feedback.

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark VI DCS runs firmware ≥6.0 to unlock GE IS200VSVOH1BDC’s full dual-channel functionality and LVDT compatibility. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its servo control circuits are sensitive to electrostatic discharge. Verify redundant 24V DC input from GE DS200TPSAG1A meets the ±15% tolerance, and label wiring (e.g., “CH01-FUEL-VALVE-01” for fuel valve connections) to avoid cross-channel errors—critical for maintaining control precision.

Maintenance recommendations: Perform monthly visual inspections of GE IS200VSVOH1BDC to check for loose backplane connections, corrosion on pins, or illuminated fault LEDs; clean the module with compressed air (30 PSI max) to remove dust. Quarterly, calibrate channels using a precision current meter and LVDT simulator, verifying position accuracy within ±0.2% of full scale. Semi-annually, test valve response via the DCS HMI by sending step commands and validating 90% response within 10ms. Replace GE IS200VSVOH1BDC if position error exceeds ±1%, LVDT feedback faults persist, or output channels fail to respond.

Product Guarantee

GE guarantees the performance and reliability of GE IS200VSVOH1BDC with a 1-year standard warranty, covering all material defects, workmanship issues, and compliance with CE/UL standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI valve control systems and can assist with configuring GE IS200VSVOH1BDC’s channels, troubleshooting LVDT feedback, and validating position accuracy. For critical applications (e.g., grid-connected power turbines), GE offers extended warranty options (up to 2 years) and on-site commissioning services, where certified technicians verify GE IS200VSVOH1BDC’s control precision and environmental resilience. Additionally, GE provides repair services for GE IS200VSVOH1BDC in OEM-approved facilities, restoring the module to factory specifications with a 1-year post-repair warranty—ensuring long-term reliability for turbine valve control systems.