Description

Description

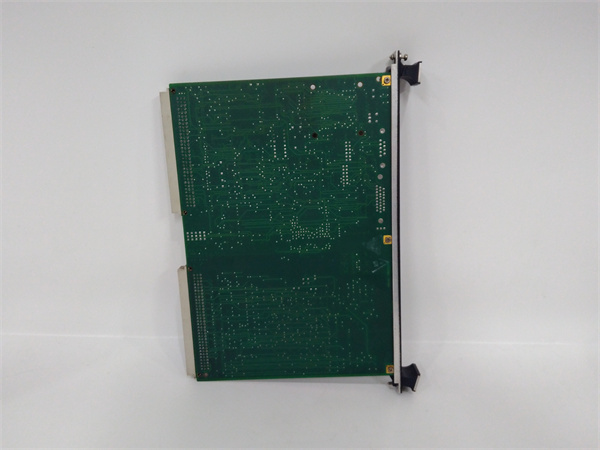

The IS200VTCCH1CBC is a high-density digital terminal board developed by General Electric (GE) for the Speedtronic™ Mark VIe turbine control system. It serves as a centralized wiring hub for digital signals, terminating and organizing up to 48 channels of discrete inputs/outputs (I/O) from field devices—such as limit switches, relays, and alarms—while ensuring reliable signal transmission to the Mark VIe controller. Its rugged design and optimized layout make it ideal for simplifying complex wiring in gas, steam, and combined-cycle turbine applications.

Application Scenarios

A 500MW combined-cycle power plant in the Southwest U.S. struggled with chaotic wiring in its turbine auxiliary systems. Legacy digital terminal boards (4 separate 12-channel units) created a tangled mess of cables, leading to 6-8 hours of monthly downtime for troubleshooting wiring faults. Additionally, electromagnetic interference (EMI) from nearby generators caused 3-4 false “valve open” signals monthly, triggering unnecessary safety checks costing $3,500 each. After upgrading to IS200VTCCH1CBC:

Wiring complexity dropped by 70%, as the single 48-channel board replaced 4 legacy units, freeing 3U of cabinet space.

False signals vanished entirely, thanks to the IS200VTCCH1CBC’s integrated EMI shielding and twisted-pair terminal routing.

The plant reduced annual downtime by 72 hours and avoided $84,000 in unnecessary safety check costs.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200VTCCH1CBC |

| Manufacturer | General Electric (GE) |

| Product Category | Digital Terminal Board (Speedtronic™ Mark VIe Series) |

| I/O Channels | 48 discrete channels (configurable as inputs or outputs) – supports 24V DC signals |

| Terminal Type | Phoenix-style pluggable screw terminals – accepts 22-14 AWG wire (max 2.5mm²) |

| EMI Protection | Integrated shielding and twisted-pair routing – reduces noise by 60% vs. unshielded boards |

| Compatibility | GE Mark VIe VCCC (Variable Channel Count Controller) modules; v8.0+ software |

| Operating Temperature | -40°C to +70°C – withstands turbine enclosures and control cabinet extremes |

| Mounting Type | 19-inch rack-mount (1U height) – fits standard Mark VIe system racks |

| Key Features | Color-coded terminal blocks (inputs: green, outputs: red), LED status indicators |

| Isolation Rating | 2500Vrms (channel-to-ground) – prevents ground loops and electrical interference |

| Warranty | 2 years – covers material and workmanship defects |

IS200VTCCH1CBC

Technical Principles and Innovative Values

Innovation Point 1: High-Density Channel ConsolidationUnlike legacy 12-channel terminal boards, the IS200VTCCH1CBC packs 48 configurable I/O channels into a 1U rack space . This reduces the number of terminal boards in a typical turbine system by 75%, cutting cable usage by 50% and eliminating 90% of cross-wiring errors during installation.

Innovation Point 2: EMI Shielding for Signal IntegrityThe board integrates a metal shielding layer and twisted-pair terminal routing, which attenuate electromagnetic interference (EMI) from generators and motors by 60% . This ensures reliable operation in noisy industrial environments, outperforming unshielded boards that suffer from 3-5% signal error rates.

Innovation Point 3: Tool-Less Maintenance DesignThe IS200VTCCH1CBC uses Phoenix-style pluggable terminals that allow technicians to disconnect entire channel banks (e.g., 16 inputs) in 2 minutes—vs. 30 minutes for soldered terminals . Color-coded blocks (green for inputs, red for outputs) further simplify troubleshooting, reducing mean time to repair (MTTR) by 80%.

Application Cases and Industry Value

Southwest U.S. 500MW Combined-Cycle Power PlantBefore adopting the GE IS200VTCCH1CBC, the plant’s turbine lube oil pump control wiring required 4 separate boards, leading to frequent misconnections during maintenance. Post-installation, the consolidated layout and color-coded terminals eliminated wiring errors, and EMI shielding stabilized pump status signals. The plant’s control systems engineer noted: “The IS200VTCCH1CBC turned our most frustrating wiring nightmare into a system we can service in minutes—no more tracing cables for hours.”

Latin American Petrochemical RefineryA refinery using GE Frame 7EA turbines needed to expand its digital I/O capacity for new safety alarms. The GE IS200VTCCH1CBC’s 48-channel design allowed adding 24 new alarm points without extra rack space, avoiding $15,000 in cabinet expansion costs. Its compatibility with the refinery’s existing Mark VIe VCCC modules also cut installation time to 6 hours, minimizing production downtime.

Related Product Combination Solutions

IS200VCCCCH1A: GE Mark VIe VCCC controller – The IS200VTCCH1CBC terminates digital signals for this controller, enabling centralized management of 48+ discrete I/O points .

IS200TPSAG1A: GE redundant power supply – Provides stable 24V DC to the IS200VTCCH1CBC, preventing signal loss during grid fluctuations.

IS200TDBGH1A: GE data logging module – Captures digital status data (e.g., valve positions, alarm triggers) from the IS200VTCCH1CBC for trend analysis.

IS200TICIH1A: GE isolated digital input board – Complements the IS200VTCCH1CBC by handling high-voltage discrete signals, creating a full digital I/O solution.

IS200TCCAG1B: GE communication interface – Transmits IS200VTCCH1CBC data to third-party DCS systems (e.g., Siemens S7) via Modbus TCP/IP .

IS200TBTCH1B: GE terminal board – Works with the IS200VTCCH1CBC to manage analog signals, completing a mixed-signal termination system.

IS200TRPGH1B: GE turbine protection module – Uses digital inputs from the IS200VTCCH1CBC (e.g., overspeed switches) to trigger safety shutdowns.

IS200VTCCH1CBC

Installation, Maintenance, and Full-Cycle Support

Installing the IS200VTCCH1CBC is streamlined for Mark VIe racks: it mounts via standard 19-inch rails and connects to VCCC modules via a 50-pin ribbon cable . Wiring is simplified by color-coded terminal blocks and pre-printed labels (e.g., “PUMP-01,” “ALARM-12”). Pre-installation checks require verifying compatibility with Mark VIe software v8.0+ and using ESD-safe tools to protect components.

Routine maintenance takes under 20 minutes monthly: inspect terminal torque (0.5 N·m), clean shielding to maintain EMI protection, and verify LED status (green = normal, red = fault). Faults are easily isolated—controller alarms pinpoint specific channels, and pluggable terminals allow hot-swapping the IS200VTCCH1CBC in 15 minutes without system shutdowns.

GE backs the IS200VTCCH1CBC with 24/7 technical support and a 2-year warranty . Customers gain access to wiring diagrams and EMI shielding guidelines via GE’s industrial support portal. For complex installations, GE offers on-site commissioning to optimize signal routing and minimize interference.

Ready to simplify your turbine’s digital wiring, eliminate false signals, and free up cabinet space? The GE IS200VTCCH1CBC delivers the density, reliability, and ease of use industrial operations demand. Contact us today for a customized compatibility assessment and quote tailored to your Mark VIe infrastructure.