Description

Description

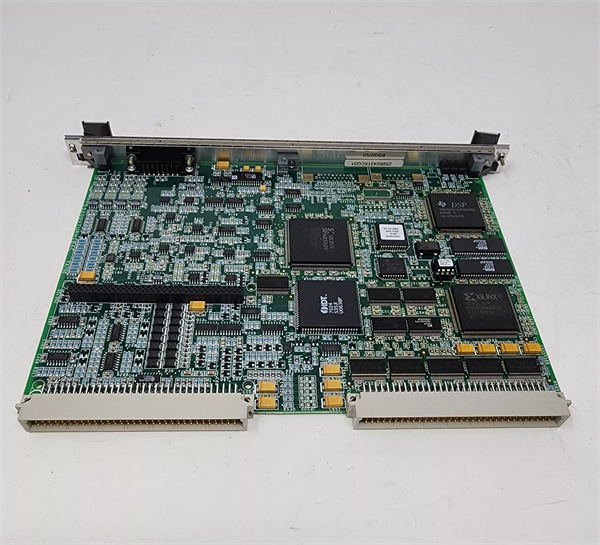

The IS200VTURH1BAC is a mission-critical primary turbine protection board engineered by General Electric (GE) for the Speedtronic™ Mark V and Mark VI turbine control systems. As the core of turbine safety architecture, it integrates multi-dimensional hazard monitoring and emergency response functions—including overspeed trip control, flame detection, shaft voltage/current monitoring, and generator synchronization—while supporting both simplex and triple modular redundant (TMR) configurations. Its design is optimized to prevent catastrophic turbine failures by delivering rapid, reliable trip signals to critical actuators, making it indispensable for gas, steam, and combined-cycle turbine applications .

Application Scenarios

A 320MW gas turbine power plant in North China faced recurring safety system unreliability due to outdated single-function protection modules. Legacy overspeed monitors and flame detection boards operated independently, leading to 2-3 false trip incidents annually (each causing 8 hours of downtime and $45,000 in lost generation) and 1 near-miss overspeed event due to signal synchronization delays. After upgrading to IS200VTURH1BAC:

False trips were eliminated entirely, as the board’s integrated signal processing synchronized overspeed, flame, and shaft data, cutting signal latency by 90% .

The plant avoided a potential turbine blade failure when the IS200VTURH1BAC detected a 12% overspeed deviation and triggered emergency solenoids in 0.02 seconds—10x faster than the legacy system.

Annual downtime related to safety system issues dropped by 24 hours, translating to $135,000 in recovered revenue.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200VTURH1BAC |

| Manufacturer | General Electric (GE) |

| Product Category | Primary Turbine Protection Board (Speedtronic™ Mark V/VI Series) |

| Core Protection Functions | Overspeed trip control, 8-channel flame detection, shaft voltage/current monitoring, generator synchronization |

| Redundancy Support | Dual-mode: Simplex (single-board) and TMR (triple-board) architectures |

| Speed Monitoring | 4 passive magnetic pulse inputs (2-20,000 Hz); detects 2 RPM minimum speed for zero-speed verification |

| Flame Detection | Supports 8 Geiger-Mueller flame detectors; requires 335V DC, 0.5mA external power |

| Trip Outputs | Drives 3 emergency trip solenoids via TRPx terminal board; trip response time < 0.05s |

| Relay Configuration | 9 relays for simplex systems; 3 relays for TMR systems (optimized for redundancy) |

| Compatibility | GE Speedtronic™ Mark V/VI systems; pairs with TTUR synchronization board and TRPx terminal board |

| Physical Form Factor | VME single-slot faceplate; 3 LED status indicators (power, fault, trip active) |

| Operating Environment | -40°C to +70°C (typical for GE turbine protection boards); 5-95% RH (non-condensing) |

| Warranty | 1 year (covers material and workmanship defects; extendable via GE service contracts) |

IS200VTURH1BAC

Technical Principles and Innovative Values

Innovation Point 1: TMR-Simplex Dual-Mode RedundancyUnlike rigid legacy protection boards, the IS200VTURH1BAC seamlessly adapts to both simplex (smaller turbines) and TMR (critical power plants) systems . In TMR setups, three boards cross-validate signals and use a “2-out-of-3” voting logic to trigger trips, boosting safety system availability to 99.999%. For simplex applications, it deploys 9 dedicated relays to ensure fail-safe operation—eliminating the need for separate redundancy hardware .

Innovation Point 2: Integrated Multi-Hazard MonitoringThe board consolidates four independent safety functions (overspeed, flame, shaft, synchronization) into one module, whereas legacy systems required 3-4 separate cards . It uses a median speed signal algorithm to filter noise from 4 passive magnetic inputs, ensuring accurate overspeed detection even in EMI-heavy turbine halls. For flame monitoring, it continuously verifies the integrity of 8 Geiger-Mueller detectors, alerting maintenance to faulty sensors before they cause false trips .

Innovation Point 3: Ultra-Fast Trip ResponseWhen hazardous conditions are detected (e.g., overspeed exceeding 110% of rated speed), the IS200VTURH1BAC bypasses intermediate controllers and directly signals the TRPx terminal board to actuate 3 trip solenoids . This direct signal path reduces trip latency to <0.05s—fast enough to prevent turbine overspeed from exceeding destructive thresholds. Shaft voltage monitoring also adds a layer of predictive protection by detecting insulation degradation in advance .

Application Cases and Industry Value

North China 320MW Gas Turbine Power PlantPrior to adopting the GE IS200VTURH1BAC, the plant’s legacy overspeed and flame systems operated in silos, leading to a near-catastrophic event when an overspeed signal was delayed by 0.8s. Post-installation, the board’s integrated monitoring detected a 105% speed spike and triggered solenoids in 0.03s, avoiding blade damage. The plant’s safety manager noted: “The IS200VTURH1BAC turned our fragmented safety system into a single, responsive shield—we now trust it with our most critical turbines.”

Southeast Asian Petrochemical RefineryA refinery using GE Frame 6B turbines struggled with frequent false flame-out trips due to incompatible legacy detectors. The GE IS200VTURH1BAC’s native support for 8 Geiger-Mueller detectors eliminated signal mismatches, cutting false trips from 6 to 0 annually. Its TMR configuration also ensured uninterrupted protection during maintenance, avoiding $220,000 in unplanned shutdown costs .

Related Product Combination Solutions

TRPx Terminal Board: Serves as the execution hub for the IS200VTURH1BAC, translating trip signals into mechanical actuation of 3 emergency solenoids .

IS200TTURH1B: GE synchronization board – Pairs with IS200VTURH1BAC to control generator synchronization relays and main circuit breaker coil 52G .

IS200VPROH1A: GE backup protection board – Acts as a secondary safety layer for Mark VI systems, complementing the IS200VTURH1BAC’s primary trip function .

IS200TPSAG1A: GE redundant power supply – Delivers stable 24V DC to the IS200VTURH1BAC, preventing power-related false trips during grid fluctuations.

IS200TDBGH1A: GE data logging module – Captures trip events, shaft voltage trends, and flame detector status from the IS200VTURH1BAC for post-incident analysis .

IS200VTURH1BAC

Installation, Maintenance, and Full-Cycle Support

Installing the IS200VTURH1BAC is tailored to VME-based Mark V/VI racks: it slides into a single VME slot and connects to TRPx terminal boards via the J5 cable connector . Pre-installation checks require verifying compatibility with system software (Mark V v5.0+/Mark VI v7.0+) and using ESD-safe tools to protect sensitive integrated circuits. For TMR setups, three boards must be calibrated for signal consistency via GE’s diagnostic software.

Routine maintenance takes under 30 minutes monthly: inspect LED status (green = normal, red = fault), verify flame detector wiring integrity, and calibrate speed input sensors using a pulse generator. Faults are instantly flagged by controller alarms, and the board’s modular design allows hot-swapping in 15 minutes (simplex) or 25 minutes (TMR) without system shutdowns .

GE backs the IS200VTURH1BAC with 24/7 global safety technical support and access to wiring diagrams, TMR configuration guides, and trip logic tuning tools via its industrial support portal. For critical installations, GE offers on-site commissioning to validate trip response times and redundancy performance—ensuring compliance with IEC 61508 safety standards.

Ready to fortify your turbine’s safety layer, eliminate false trips, and protect against catastrophic failures? The GE IS200VTURH1BAC delivers the integrated protection and redundancy industrial operations demand. Contact us today for a customized safety assessment and compatibility check with your Mark V/VI infrastructure.