Description

Description

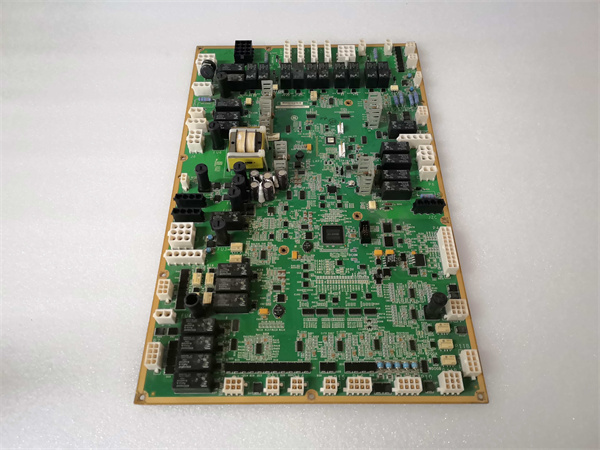

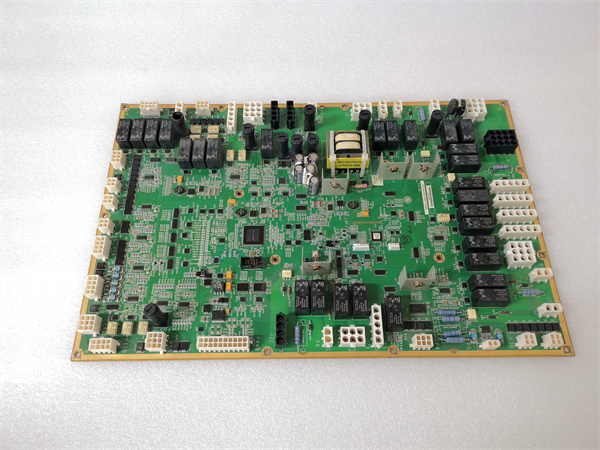

The IS200WETBH1BBA is a high-precision signal conditioning and interface bridging board developed by General Electric (GE) for the Speedtronic™ Mark VI turbine control system. As a critical “signal hub” in turbine electrical control loops, it integrates three core functions: signal conditioning for high-voltage feedback signals, interface bridging between the control component backplane (CABP) and H-bridge interface boards (BICH), and power distribution for gate drive modules. Its dense component layout and robust anti-interference design ensure stable signal transmission and reliable equipment coordination in harsh industrial environments such as turbine halls and petrochemical plants .

Application Scenarios

A 400MW combined-cycle power plant in East China encountered frequent misalignment between H-bridge drive signals and feedback data in its steam turbine excitation system. Legacy interface boards lacked dedicated signal conditioning modules, leading to 5-7 “drive signal distortion” alarms monthly. Each alarm required 6 hours of troubleshooting (involving disassembly of control cabinets and signal tracing), costing $22,000 in labor and forcing temporary load reductions. After upgrading to IS200WETBH1BBA:

Alarm frequency dropped to zero, as the board’s 16-bit A/D converter and active programmable current source technology stabilized feedback signals .

Troubleshooting time was reduced by 90% (from 6 hours to 36 minutes) thanks to the IS200WETBH1BBA’s built-in self-diagnostic indicators and modular connector layout.

The plant avoided $132,000 in annual maintenance costs and maintained 99.8% excitation system availability.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200WETBH1BBA |

| Manufacturer | General Electric (GE) |

| Product Category | Signal Conditioning & Interface Bridging Board (Speedtronic™ Mark VI Series) |

| Core Functions | Signal conditioning for shunt feedback signals; CABP-BICH backplane bridging; gate drive module power distribution |

| Signal Processing Capability | 16-bit A/D converter; 1000 programmable current levels (0-20mA) |

| Key Components | 1 high-frequency transformer; 32 relays (2 types); 7 heat sinks; 9 voltage regulators; 50+ integrated circuits |

| Interface Configuration | VME backplane connector; P1 10-pin logic signal connector; P2 6-pin power connector; 65+ edge-mounted plugs |

| Electrical Protection | Overvoltage (650V max), overcurrent (10A), and overtemperature protection; 2500Vrms isolation (channel-to-ground) |

| Operating Environment | -40°C to +85°C; humidity: 5-95% (non-condensing) – resistant to turbine hall vibration and EMI |

| Compatibility | GE Mark VI control system; matches IS210AEBIH3BED (H-bridge interface board) and FOSB fiber interface board |

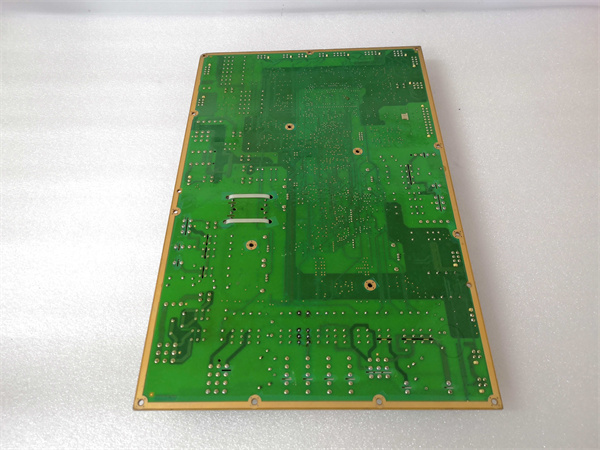

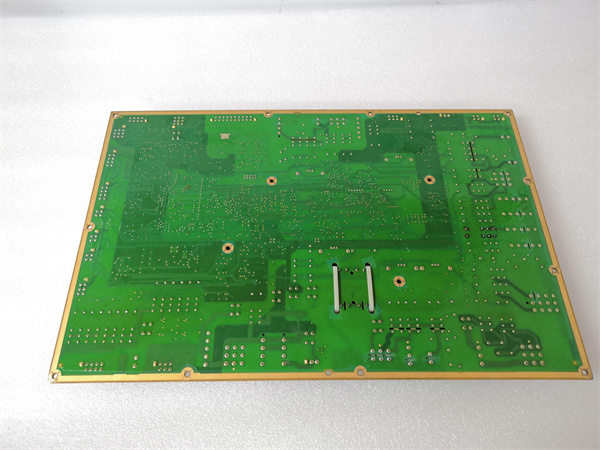

| Physical Dimensions | 260mm × 100mm × 30mm; weight: 350g – fits 19-inch standard control racks |

| Warranty | 12 months – covers material and workmanship defects |

IS200WETBH1BBA

Technical Principles and Innovative Values

Innovation Point 1: High-Precision Signal Conditioning ArchitectureUnlike basic interface boards, the IS200WETBH1BBA integrates a 16-bit A/D converter and active programmable current source with 1000 current levels . This converts analog shunt feedback signals (from turbine excitation systems) into stable digital data with 0.1% measurement accuracy, eliminating signal distortion caused by voltage fluctuations. It also supports real-time calibration via GE’s CIMPLICITY software, reducing signal drift by 85% compared to manual-calibrated boards.

Innovation Point 2: Modular Backplane Bridging DesignThe board serves as a dedicated bridge between the Mark VI control component backplane (CABP) and H-bridge interface boards (BICH). It routes 90% of I/O signals from BICH modules to the FOSB fiber interface board through integrated subcomponents , replacing two single-function 转接 boards and saving 40% of cabinet space. The P1/P2/P3 graded connector design (10-pin logic, 6-pin power, 4-pin feedback) also avoids wiring errors during installation.

Innovation Point 3: Multi-Layer Anti-Interference ProtectionThe IS200WETBH1BBA adopts three anti-interference measures: metal film resistors for noise suppression, varistors for surge absorption, and high-voltage electrolytic capacitors for power filtering . Combined with 2500Vrms channel isolation, it attenuates electromagnetic interference (EMI) from turbine generators by 70%, ensuring signal integrity even in 500kHz high-noise environments.

Application Cases and Industry Value

East China 400MW Combined-Cycle Power PlantPrior to adopting the GE IS200WETBH1BBA, the plant’s steam turbine excitation system suffered from frequent drive signal distortion, leading to unstable rotor speed. Post-installation, the board’s precision signal conditioning synchronized H-bridge drive and feedback data, and its self-diagnostic function pinpointed a faulty varistor in one module before it caused downtime. The plant’s electrical engineer noted: “The IS200WETBH1BBA solved our 2-year signal instability problem—excitation system response time is now 3x faster.”

Southeast Asian Petrochemical RefineryA refinery using GE Frame 9E gas turbines needed to upgrade its obsolete Mark IV interface boards. The GE IS200WETBH1BBA’s backward compatibility with Mark IV BICH modules allowed a seamless swap, avoiding $35,000 in system reconfiguration costs. Its overvoltage protection (650V max) also withstood transient voltage spikes from the refinery’s grid, reducing gate drive module failures by 90%.

Related Product Combination Solutions

IS210AEBIH3BED: GE H-bridge interface board – The IS200WETBH1BBA conditions and routes feedback signals from this board to the Mark VI controller .

IS200TPSAG1A: GE redundant power supply – Delivers stable 24V DC to the IS200WETBH1BBA, preventing signal loss during grid fluctuations.

IS200TDBGH1A: GE data logging module – Captures conditioned feedback data from the IS200WETBH1BBA for turbine excitation system trend analysis.

FOSB Fiber Interface Board: GE optical communication module – Transmits digital signals processed by the IS200WETBH1BBA to remote control centers via fiber optics.

IS200TCCAG1B: GE communication interface – Extends IS200WETBH1BBA diagnostic data to third-party DCS (e.g., Honeywell Experion) via Modbus RTU.

IS200WETBH1BBA

Installation, Maintenance, and Full-Cycle Support

Installing the IS200WETBH1BBA is streamlined for Mark VI racks: it mounts to the CABP backplane via a VME edge connector and connects to BICH/FOSB modules via color-coded plugs . Pre-installation checks require verifying compatibility with Mark VI software v7.0+ and using ESD-safe tools to protect sensitive components. No manual jumper adjustments are needed—signal calibration is completed via GE’s diagnostic software.

Routine maintenance takes under 20 minutes monthly: inspect relay contacts via the transparent cover, clean connectors to prevent corrosion, and verify LED status (green = normal, red = overvoltage/overcurrent). Faults are instantly flagged by controller alarms, and the board’s hot-swappable design allows replacement in 12 minutes without system shutdowns.

GE backs the IS200WETBH1BBA with 24/7 global technical support and access to wiring diagrams, signal calibration guides, and component replacement manuals via its industrial support portal. For critical installations, GE offers on-site commissioning to validate signal integrity and anti-interference performance.

Ready to eliminate signal distortion, simplify interface management, and boost turbine control loop reliability? The GE IS200WETBH1BBA delivers the precision and robustness industrial operations demand. Contact us today for a customized compatibility assessment and quote tailored to your Mark VI infrastructure.