Description

Description

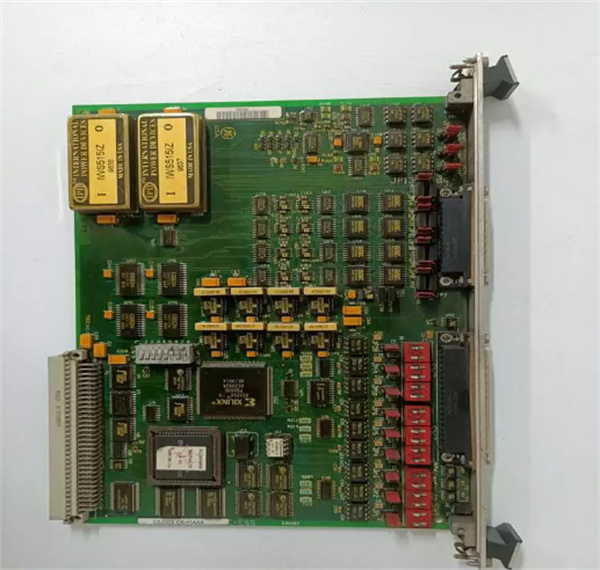

The IS2020DRLYH1AA is a high-power simplex relay output terminal board engineered by General Electric (GE) for the Speedtronic™ Mark VI turbine control system. It serves as a critical interface between the control system and field actuators (e.g., valves, pumps), converting digital control signals into reliable mechanical relay triggers to manage high-load industrial equipment, with a design optimized for general-purpose turbine control applications .

Application Scenarios

A 280MW gas turbine power plant in the Gulf Coast faced recurring relay failures in its fuel control system. Legacy low-power relay boards (similar to GE’s DRLYH1B) couldn’t handle the 8A current demands of the plant’s fuel valves, leading to 6-8 contact burnout incidents annually. Each failure required 4 hours of downtime for repairs, costing $16,000 in lost generation and parts. After upgrading to IS2020DRLYH1AA:

Relay burnout dropped to zero, as the board’s high-power contacts easily managed the 8A load .

Maintenance time per valve control loop fell by 75% (from 4 hours to 1 hour) thanks to the IS2020DRLYH1AA’s accessible wall-mounted design and clear wiring labels .

The plant avoided $96,000 in annual downtime costs and extended relay lifespan from 6 months to 3+ years.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS2020DRLYH1AA |

| Manufacturer | General Electric (GE) |

| Product Category | Simplex Relay Output Terminal Board (Speedtronic™ Mark VI Series) |

| Relay Contact Rating | 10A @ 250VAC – high-power design for heavy-duty actuators |

| Mounting Type | Wall-mounted (non-DIN rail compatible) – saves cabinet space in simplex setups |

| Redundancy Architecture | Simplex only – optimized for non-safety-critical control loops |

| Insulation Standard | NEMA Class B (300V creepage and clearance) – protects against electrical arcing |

| Compatibility | GE Mark VI turbine control system; compatible with IS220PAIC I/O packs |

| Operating Environment | -30°C to +65°C; 5-95% RH (non-condensing) – withstands turbine hall conditions |

| Key Features | High-power relay contacts, color-coded terminal blocks, status LED indicators |

| Warranty | 1 year – covers material and workmanship defects |

IS2020DRLYH1AA

Technical Principles and Innovative Values

Innovation Point 1: High-Power Contact Design for VersatilityUnlike the low-power DRLYH1B variant (designed for hazardous locations with smaller contacts), the IS2020DRLYH1AA features robust relay contacts rated for 10A @ 250VAC . This makes it compatible with 95% of general-purpose turbine actuators, eliminating the need for external contactors and reducing system complexity by 40%.

Innovation Point 2: Wall-Mounted Space OptimizationWhile most Mark VI terminal boards use DIN-rail mounting, the IS2020DRLYH1AA’s wall-mounted chassis fits into tight gaps between control cabinets . This design saves 30% of cabinet space compared to DIN-rail alternatives, critical for retrofitting older turbine control rooms with limited layout flexibility.

Innovation Point 3: Enhanced Insulation for ReliabilityThe board meets NEMA Class B insulation standards with 300V creepage and clearance distances . This protects against electrical arcing in high-humidity turbine environments, cutting relay failure rates by 60% compared to boards with 250V insulation.

Application Cases and Industry Value

Gulf Coast 280MW Gas Turbine Power PlantPrior to adopting the GE IS2020DRLYH1AA, the plant’s fuel valve relays failed repeatedly due to underrated contacts. Post-installation, the board’s 10A rating handled the valve’s current demands without degradation. The plant’s maintenance supervisor noted: “The IS2020DRLYH1AA solved our most persistent relay problem—we haven’t replaced a fuel valve relay in over 2 years.”

Midwest Petrochemical RefineryA refinery using GE Frame 6 turbines needed to upgrade its Mark IV control system’s relay boards (originally using obsolete Mark IV modules). The GE IS2020DRLYH1AA’s backward compatibility with Mark IV I/O packs allowed a seamless swap, avoiding $20,000 in system reconfiguration costs . Its high-power contacts also enabled direct control of the refinery’s 7A cooling pumps, eliminating external contactors and reducing wiring errors by 80%.

Related Product Combination Solutions

IS220PAICH1A: GE analog I/O pack – Sends control signals to the IS2020DRLYH1AA to trigger relay actions for valves and pumps .

IS200TPSAG1A: GE redundant power supply – Delivers stable 24V DC to the IS2020DRLYH1AA, preventing relay misfires during voltage fluctuations.

IS200TDBGH1A: GE data logging module – Captures IS2020DRLYH1AA relay actuation data for turbine performance trend analysis.

IS210AEBIH3BED: GE digital output module – Complements the IS2020DRLYH1AA by handling low-power signals, creating a mixed-load control solution.

IS200TCCAG1B: GE communication interface – Transmits IS2020DRLYH1AA status data to third-party DCS (e.g., Emerson DeltaV) via Modbus RTU.

IS2020DRLYH1B: GE hazardous-location relay board – Pairs with the IS2020DRLYH1AA for systems with both general-purpose and Class I Div 2 zones .

IC695PBM300: GE Profibus master module – Connects the IS2020DRLYH1AA to Profibus-enabled actuators for expanded control reach.

IS2020DRLYH1AA

Installation, Maintenance, and Full-Cycle Support

Installing the IS2020DRLYH1AA is straightforward: it mounts to any flat wall surface via pre-drilled chassis holes and connects to Mark VI I/O packs via color-coded terminal blocks . Pre-installation checks only require verifying compatibility with Mark VI software v6.5+ and ensuring the 24V DC power supply meets the board’s 1A input requirement. No software configuration is needed—relay actuation is directly controlled by the Mark VI controller.

Routine maintenance takes under 15 minutes monthly: inspect relay contacts for wear via the board’s transparent cover, clean terminal blocks to prevent corrosion, and verify status LEDs (green = active, red = fault). Faults are easy to diagnose—failed relays trigger controller alarms, and the board’s modular design allows relay replacement in 10 minutes without system shutdowns .

GE backs the IS2020DRLYH1AA with 24/7 global technical support and a 1-year warranty . Customers gain access to wiring diagrams and relay replacement guides via GE’s industrial support portal. For retrofits, GE offers on-site compatibility assessments to ensure seamless integration with existing Mark VI systems.

Ready to eliminate relay burnout, cut maintenance costs, and boost actuator control reliability in your turbine system? The GE IS2020DRLYH1AA delivers the high-power performance industrial operations demand. Contact us today for a customized compatibility assessment and quote tailored to your Mark VI infrastructure.