Description

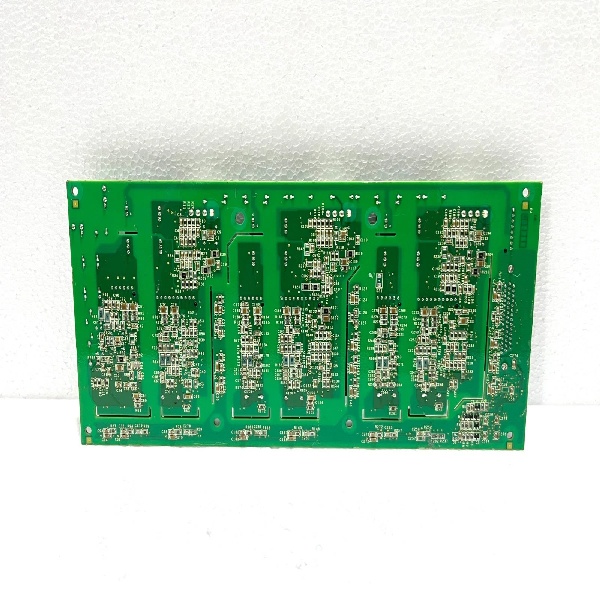

GE IS210AEBIH1BAA Mark VIe Digital Input Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS210AEBIH1BAA** Manufacturer | GE General Electric Product Category | Industrial Digital Input Module Series | Mark VIe (Turbine Control System) Input Channels | 16 Isolated Differential Channels Input Type | Dry Contact (NO/NC), 24V DC Wet Contact Input Voltage Range | 18-30V DC (Wet Contact) Response Time | ≤1ms Isolation Voltage | 500V AC (Channel to Channel, Channel to Ground) Input Current | 5mA @ 24V DC (Wet Contact) Power Supply | 24V DC (from Mark VIe Power Module) Operating Temperature | 0°C to 60°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 12 (Chassis Mount) Physical Dimensions | 140mm × 100mm × 30mm Certifications | UL 508, CE, CSA, IEC 61131-2

Product Introduction

The **GE IS210AEBIH1BAA** is a high-reliability digital input module engineered for GE’s Mark VIe turbine control system, specializing in the collection and transmission of discrete signals from critical turbine components. As a core discrete data acquisition unit in GE’s industrial portfolio, the **GE IS210AEBIH1BAA** captures on/off status signals—such as turbine valve position switches, emergency stop contacts, bearing temperature limit switches, and pump running status—and converts them into standardized digital data for Mark VIe control modules (like the **IS210MACCH1A**). Its 16-channel isolated design and dual-input compatibility make it indispensable for power plants and industrial turbine systems where accurate discrete status monitoring is crucial for safe and reliable operation.

What distinguishes the **GE IS210AEBIH1BAA** is its robust isolation design and seamless integration with the Mark VIe ecosystem. Leveraging GE’s expertise in turbine control and discrete signal processing, the **GE IS210AEBIH1BAA** features channel-to-channel isolation to prevent signal crosstalk and interference—critical in the high-electromagnetic environment near turbine generators. By delivering fast and accurate discrete data to the control system, it enables real-time status monitoring, immediate fault response, and compliance with industrial safety standards, directly enhancing the operational safety and reliability of the entire turbine control system.

Core Advantages and Technical Highlights

Multi-Channel Isolated Design: The **IS210AEBIH1BAA** is equipped with 16 fully isolated differential channels, each capable of independent configuration for dry or wet contact inputs. Channel-to-channel isolation (500V AC) eliminates signal interference between channels, ensuring accurate data collection even when monitoring multiple high-voltage or high-noise discrete signals simultaneously—such as turbine fuel valve switches and generator breaker statuses.

Dual-Input Compatibility: The module supports both dry contact (NO/NC) and 24V DC wet contact inputs, adapting to a wide range of turbine discrete sensors and switches. Dry contact mode is ideal for monitoring mechanical limit switches (e.g., turbine shaft position), while wet contact mode is suitable for active sensors with 24V DC output—eliminating the need for additional signal converters and simplifying system integration.

Fast Response and High Reliability: With a response time of ≤1ms, the **IS210AEBIH1BAA** captures rapid discrete signal changes—such as emergency stop button presses or valve fault triggers—ensuring the **IS210MACCH1A** control module receives immediate status updates to execute protective actions. Its rugged design and wide input voltage range (18-30V DC) ensure stable operation even in voltage-fluctuating industrial environments.

Seamless Mark VIe Integration: The **IS210AEBIH1BAA** communicates directly with the Mark VIe backplane via GE’s proprietary protocol, synchronizing discrete data with the **IS210MACCH1A** and HMI interfaces in real time. It supports online configuration and diagnostic testing via Mark VIe Configuration Studio, allowing maintenance teams to troubleshoot channel faults without powering down the entire control system—minimizing maintenance downtime.

IS210AEBIH1BAA

Typical Application Scenarios

In large-scale steam turbine power plants, the **IS210AEBIH1BAA** serves as the primary discrete input module for the Mark VIe system. It monitors 16 critical discrete signals, including turbine start/stop status, high-pressure valve position switches, bearing temperature high-limit contacts, and generator breaker status. When a bearing temperature limit switch triggers, the module transmits the fault signal to the **IS210MACCH1A** in ≤1ms, prompting the control system to initiate a protective shutdown and prevent equipment damage.

For industrial gas turbine systems, the **IS210AEBIH1BAA** monitors discrete signals from fuel supply systems, including fuel pump running status, fuel filter clogging alerts, and emergency fuel cutoff valve positions. Its isolated channels prevent interference from fuel system electrical components, ensuring accurate status reporting. The module’s compatibility with both dry and wet contacts allows it to integrate with legacy mechanical switches and modern active sensors seamlessly.

In hydroelectric power plants, the **IS210AEBIH1BAA** collects discrete signals from turbine governor systems, such as wicket gate limit switches, emergency stop button status, and water intake valve position contacts. Its wide operating temperature range and rugged design withstand the high-humidity environment of hydro plants, while fast response time ensures immediate transmission of critical status changes—such as a sudden water level drop triggering a valve closure signal.

Related Model Recommendations

**IS210AEBIH2BAA**: 32-channel variant of **IS210AEBIH1BAA**, ideal for large Mark VIe systems requiring extended discrete signal monitoring, such as multi-turbine power plants or complex industrial processes.

**IS210MACCH1A**: Mark VIe control module that processes discrete data from **IS210AEBIH1BAA**, executing protective actions and status monitoring for turbine systems.

**IS210BPPBH2B**: Mark VIe power supply module that provides stable 24V DC power to **IS210AEBIH1BAA**, ensuring reliable discrete signal acquisition and data transmission.

**IS210BAPAH1A**: Mark VIe analog input module that complements **IS210AEBIH1BAA**, collecting continuous sensor data to provide comprehensive turbine status visibility.

**IS210BDAOH1A**: Mark VIe digital output module that works with **IS210AEBIH1BAA**, executing discrete control commands (e.g., valve actuation) based on input status signals.

**IC754VSF12CTD-JH**: GE VersaMax HMI that displays real-time discrete status data from **IS210AEBIH1BAA**, enabling operators to monitor switch positions and fault alerts intuitively.

**IS210MCCPG1A**: Mark VIe communication module that extends **IS210AEBIH1BAA**’s connectivity to plant-wide SCADA systems, facilitating remote monitoring of discrete signals.

IS210AEBIH1BAA

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS210AEBIH1BAA**, power off the Mark VIe chassis and verify backplane compatibility. Ensure the module receives stable 24V DC power from a dedicated Mark VIe power module (e.g., **IS210BPPBH2B**). Use shielded twisted-pair cables for sensor connections to minimize electromagnetic interference. Configure each channel’s input type (dry/wet contact) and fault detection thresholds via Mark VIe Configuration Studio, and label wires clearly according to the turbine signal schematic.

Maintenance suggestions: Conduct monthly visual inspections of **IS210AEBIH1BAA**, checking for loose wiring, damaged connectors, and dust accumulation—clean the module with a dry anti-static brush. Test each channel quarterly using a signal simulator to verify response time and input accuracy, ensuring no channels are faulty. Verify isolation integrity annually using a megohmmeter (500V DC) to confirm channel-to-channel and channel-to-ground insulation. Ensure the control cabinet maintains 0°C to 60°C and adequate ventilation, and update the module’s firmware annually via GE’s technical support platform.

Service and Guarantee Commitment

GE General Electric provides a 36-month quality guarantee for the **IS210AEBIH1BAA**, covering manufacturing defects, channel failures, response time degradation, and isolation integrity issues under normal operating conditions. Our global technical support team offers 24/7 assistance, including remote configuration guidance, channel fault diagnosis, and firmware update support. Customers receive access to GE’s Mark VIe Configuration Studio and calibration documentation for the **IS210AEBIH1BAA** throughout the guarantee period. Priority service clients benefit from 48-hour replacement of defective modules to minimize turbine discrete monitoring downtime.