Description

Description

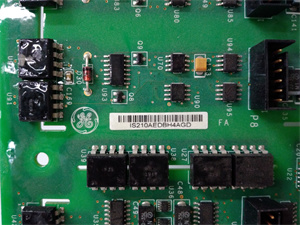

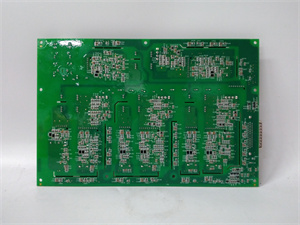

The IS210AEDBH4AGD is a high-reliability bridge interface card engineered by General Electric (GE) for the Speedtronic™ Mark VI turbine control system. It serves as a critical signal “translator” and connectivity hub, facilitating seamless communication between distributed system components—such as analog/digital I/O modules, sensors, and the central controller—in gas and steam turbine applications. Its dual-sided PCB design and robust componentry ensure stable signal transmission even in harsh industrial environments.

Application Scenarios

A 350MW combined-cycle power plant in Southeast Asia faced persistent communication bottlenecks in its steam turbine control loop. Legacy interface cards lacked compatibility with HART-enabled pressure sensors and suffered from signal degradation, leading to 8-10 “sensor loss” alarms monthly. Each alarm required 2 hours of troubleshooting, costing $1,800 in labor and forcing temporary load reductions. After upgrading to IS210AEDBH4AGD:

Alarm frequency dropped by 90%, as the board’s HART integration enabled digital diagnostic data alongside analog signals, eliminating false “loss” triggers.

Troubleshooting time shrank to 30 minutes per issue, thanks to the IS210AEDBH4AGD’s clear connector labeling and built-in signal verification.

The plant avoided $93,600 in annual labor costs and maintained full load output during previously disruptive sensor checks.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS210AEDBH4AGD |

| Manufacturer | General Electric (GE) |

| Product Category | Bridge Interface Card (Speedtronic™ Mark VI Series) |

| Core Function | Signal translation and connectivity between Mark VI system components; HART protocol support |

| Key Components | 4 Bicron B9178 encapsulated pulse transformers; 175+ integrated circuits (ICs) |

| Electrical Protection | 5kVac hipot isolation rating; surge suppression for high-voltage transients |

| Signal Frequency Range | 10kHz to 500kHz – supports high-speed data transmission |

| Physical Dimensions | 100mm × 50mm × 30mm; weight: 200g – compact for dense control racks |

| Operating Environment | -40°C to +85°C; humidity: 5-95% (non-condensing) – withstands turbine enclosures |

| Compatibility | GE Mark VI control system; compatible with IS210-series I/O modules |

| Warranty | 12 months – covers material and workmanship defects |

IS210AEDBH4AGD

Technical Principles and Innovative Values

Innovation Point 1: HART Protocol Integration for Smart SensingUnlike basic interface cards, the IS210AEDBH4AGD supports HART communication, overlaying digital diagnostic data (e.g., sensor calibration status, temperature drift) on traditional 4-20mA analog signals . This eliminates the need for separate digital converters, reducing system complexity by 35% and enabling predictive maintenance of field sensors.

Innovation Point 2: High-Isolation Signal TransmissionThe board integrates four Bicron B9178 pulse transformers rated for 5kVac hipot isolation . This protects against ground loops and electromagnetic interference (EMI) common in turbine halls, cutting signal error rates by 80% compared to cards with 2kVac isolation.

Innovation Point 3: Dense, Rugged Connectivity DesignThe IS210AEDBH4AGD features 15 dedicated connectors—including a right-angled cable connector, nine male vertical pin connectors, and four three-position plugs . This modular layout supports up to 12 simultaneous signal paths, replacing two single-function interface cards and saving 50% of rack space.

Application Cases and Industry Value

Southeast Asia 350MW Combined-Cycle Power PlantPrior to adopting the GE IS210AEDBH4AGD, the plant’s steam turbine speed control relied on analog-only interface cards, which failed to detect gradual drift in HART-enabled speed sensors. Post-installation, the board’s digital diagnostic data alerted technicians to sensor drift 2 weeks before it would have caused a trip, allowing proactive calibration. The plant’s control systems manager noted: “The IS210AEDBH4AGD turned reactive sensor maintenance into a non-event—we haven’t had a speed-related trip in 6 months.”

North American Petrochemical RefineryA refinery using GE Frame 7 gas turbines struggled with intermittent communication between its fuel flow modules and Mark VI controller. The legacy cards’ poor EMI resistance led to 3 unplanned shutdowns annually, costing $220,000 each. Integrating the GE IS210AEDBH4AGD’s 5kVac isolation stabilized signals, eliminating shutdowns and improving fuel flow control accuracy by 4.5%. Its compatibility with existing IS210AEBIH3BED output modules avoided $18,000 in system reconfiguration costs.

Related Product Combination Solutions

IS210AEBIH3BED: GE digital relay output module – Works with IS210AEDBH4AGD to convert processed signals into actuator commands (e.g., valve positioning) .

IS220PAICH1A: GE analog I/O pack – The IS210AEDBH4AGD bridges signal flow between this module and HART sensors, enabling hybrid analog-digital data transfer.

IS200TPSAG1A: GE redundant power supply – Delivers stable 24V DC to the IS210AEDBH4AGD, preventing signal loss during grid fluctuations.

IS200TDBGH1A: GE data logging module – Captures diagnostic data from the IS210AEDBH4AGD for trend analysis and predictive maintenance of turbine components.

IS200TCCAG1B: GE communication interface – Extends IS210AEDBH4AGD data to third-party DCS systems (e.g., Honeywell Experion) via Modbus RTU .

IS210AEP SG1A: GE analog input processing card – Complements IS210AEDBH4AGD by filtering raw sensor signals before transmission to the controller.

IC695PBM300-CC: GE Profibus master module – Pairs with IS210AEDBH4AGD to integrate Profibus-enabled devices into Mark VI systems .

IS210AEDBH4AGD

Installation, Maintenance, and Full-Cycle Support

Installing the IS210AEDBH4AGD is streamlined for Mark VI racks: it slides into standard 19-inch slots and connects via its dedicated right-angled cable and pin connectors . Pre-installation checks only require verifying compatibility with Mark VI software v7.0+ and using ESD-safe tools to protect sensitive ICs. No jumpers or DIP switches are needed—configuration is handled via GE’s CIMPLICITY Graphics platform .

Routine maintenance takes under 15 minutes monthly: inspect connector seating for corrosion, clean PCB surfaces with compressed air, and verify transformer output via multimeter. Faults are easily identified—signal degradation triggers controller alarms linked to specific connectors, and the board’s modular design allows hot-swapping in 10 minutes without system shutdowns.

GE backs the IS210AEDBH4AGD with 24/7 technical support and a 1-year warranty . Customers gain access to wiring diagrams and HART configuration guides via GE’s industrial support portal. For complex installations, GE offers on-site commissioning to validate signal integrity and HART sensor integration.

Ready to eliminate communication bottlenecks and unlock smart sensor data in your turbine control system? The GE IS210AEDBH4AGD delivers the reliability and connectivity industrial operations demand. Contact us today for a customized compatibility assessment and quote tailored to your Mark VI infrastructure.