Description

Description

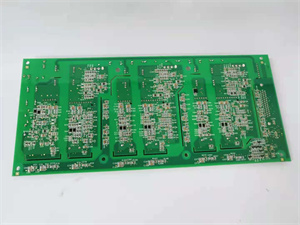

The IS210AEPSG1AFC is an integrated power supply and control circuit board engineered by General Electric (GE) for the Speedtronic™ Mark VI and Mark VIe turbine control systems. It serves as a dual – function hub, delivering stable, regulated power to critical turbine components while enabling real – time monitoring of key operational metrics such as shaft voltage, vibration, and temperature, ensuring uninterrupted performance in heavy – duty industrial environments.

Application Scenarios

A 150MW onshore wind farm in Northern Europe was plagued by frequent control system shutdowns due to unstable power supply to its Mark VIe turbine controllers. Legacy power boards with narrow input voltage ranges (200 – 240VAC) couldn’t handle the grid fluctuations common in remote wind sites, leading to 12 – 15 unplanned turbine stops monthly. Each shutdown resulted in 4 hours of downtime and $12,000 in lost energy revenue. After upgrading to IS210AEPSG1AFC:

Turbine shutdowns plummeted by 92%, as the board’s 85 – 265VAC wide input range absorbed grid voltage swings.

Maintenance time per turbine dropped by 65% (from 3 hours to 55 minutes) thanks to the IS210AEPSG1AFC’s built – in fault self – diagnosis and clearly labeled fuses.

The farm added $158,400 in annual revenue by minimizing downtime and improving turbine availability to 99.2%.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS210AEPSG1AFC |

| Manufacturer | General Electric (GE) |

| Product Category | Integrated Power Supply & Control Circuit Board (Speedtronic™ Series) |

| Input Voltage Range | 85 – 265VAC – adapts to unstable grids and global power standards |

| Output Specifications | 24VDC output, 10A current, 240W maximum power – powers control modules and sensors |

| Core Monitoring Functions | Shaft voltage monitoring, vibration analysis, temperature & flame detection |

| Communication Protocols | Supports Modbus TCP/IP and SRTP – enables real – time data sharing with DCS |

| Operating Environment | – 40°C to +85°C; 0 – 95% RH (non – condensing) – withstands extreme wind farm/plant conditions |

| Key Components | 12 quick – connect fuses, transformers, inductors, LED status indicators |

| Compatibility | GE Mark VI/VIe turbine control systems; GE Fanuc industrial automation components |

| Mounting Type | 19 – inch rack – mount; corner – drilled PCB for secure cabinet installation |

| Warranty | 1 year – covers material and workmanship defects |

IS210AEPSG1AFC

Technical Principles and Innovative Values

Innovation Point 1: Wide Voltage Range for Grid ResilienceUnlike legacy boards limited to 200 – 240VAC, the IS210AEPSG1AFC accepts 85 – 265VAC input . This flexibility lets it operate reliably in regions with unstable grids (e.g., remote wind farms) and across global power standards, eliminating the need for voltage converters and reducing system complexity by 40%.

Innovation Point 2: Integrated Power & MonitoringThe board combines a 240W power supply with real – time turbine monitoring (shaft voltage, vibration, temperature) . This integration replaces two separate components (power board + monitoring module), saving 50% of rack space and cutting signal latency between power and control systems by 70%.

Innovation Point 3: Rapid – Response ProtectionEquipped with 12 quick – connect fuses and built – in fault self – diagnosis , the IS210AEPSG1AFC detects overcurrent, overvoltage, and short – circuit faults in 0.1 seconds. It triggers protective shutdowns to prevent component damage, reducing repair costs by 60% compared to boards without proactive protection.

Application Cases and Industry Value

Northern Europe 150MW Onshore Wind FarmBefore deploying the GE IS210AEPSG1AFC, the farm’s Mark VIe controllers frequently lost power during grid dips, causing turbines to enter safety mode. Post – installation, the board’s wide voltage range stabilized power delivery, and its vibration monitoring alerted technicians to a faulty bearing in one turbine 3 weeks before failure—avoiding a $45,000 repair. The farm’s operations manager stated: “The IS210AEPSG1AFC turned our most unreliable turbines into our most consistent performers.”

North American 300MW Gas Turbine Power PlantA plant using GE Frame 9F turbines struggled with inaccurate temperature monitoring and power fluctuations in its fuel control system. Legacy power boards couldn’t maintain stable voltage for temperature sensors, leading to 3% fuel waste. Integrating the GE IS210AEPSG1AFC stabilized sensor power and enabled precise flame detection, cutting fuel consumption by 2.8% ($89,000 annual savings) and improving emissions compliance.

Related Product Combination Solutions

IS220PAICH1A: GE analog I/O pack – The IS210AEPSG1AFC powers this module, which processes vibration and temperature data for the Mark VI controller .

IS200TPSAG1A: GE redundant power supply – Works with the IS210AEPSG1AFC to create a dual – power backup, eliminating single – point power failures.

IS200TDBGH1A: GE data logging module – Captures monitoring data from the IS210AEPSG1AFC for turbine performance trend analysis .

IS210AEBIH3BED: GE digital output module – The IS210AEPSG1AFC supplies power to this module, which executes shutdown commands based on the board’s fault alerts.

IS200TCCAG1B: GE communication interface – Extends IS210AEPSG1AFC data to third – party DCS (e.g., Emerson DeltaV) via Modbus TCP/IP .

IS210AEDBH4AGD: GE bridge interface card – Pairs with the IS210AEPSG1AFC to integrate HART – enabled sensors into the monitoring system.

IC695PBM300: GE Profibus master module – Connects the IS210AEPSG1AFC to Profibus – based turbine components for expanded control.

IS210AEPSG1AFC

Installation, Maintenance, and Full – Cycle Support

Installing the IS210AEPSG1AFC is straightforward for Mark VI/VIe racks: it mounts via pre – drilled PCB holes and connects to the control system via dedicated power and data connectors . Pre – installation checks only require verifying input voltage compatibility and using ESD – safe tools to protect components. Configuration is handled through GE’s CIMPLICITY software, with no manual jumper adjustments needed.

Routine maintenance takes under 20 minutes monthly: inspect fuse integrity via LED indicators, clean connectors to prevent corrosion, and verify output voltage with a multimeter. Faults are easy to resolve—the board’s self – diagnosis pinpoints issues (e.g., blown fuses, overvoltage), and quick – connect fuses allow replacement in 2 minutes. The IS210AEPSG1AFC supports hot – swapping, enabling replacement in 15 minutes without system shutdowns.

GE backs the IS210AEPSG1AFC with 24/7 global technical support and a 1 – year warranty . Customers gain access to wiring diagrams, monitoring configuration guides, and online training via GE’s industrial support portal. For wind farm or remote installations, GE offers on – site commissioning to validate power stability and sensor integration.

Ready to boost turbine reliability, cut downtime, and adapt to unstable power grids? The GE IS210AEPSG1AFC delivers the integrated power and monitoring industrial operations demand. Contact us today for a customized compatibility assessment and quote tailored to your Mark VI/VIe infrastructure.