Description

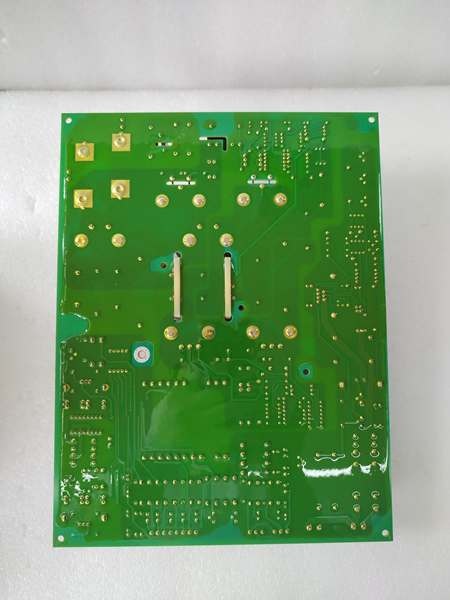

GE IS210AEPSG2B Mark VIe Power System Monitoring Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS210AEPSG2B** Manufacturer | GE General Electric Product Category | Industrial Power System Monitoring Module Series | Mark VIe (Turbine Control System) Monitoring Channels | 4 Power Module Inputs, 4 Power Module Outputs Monitored Parameters | Voltage, Current, Power Consumption, Temperature, Efficiency Input Voltage Range | 0-300V AC/DC (for monitoring) Output Current Monitoring Range | 0-50A DC Measurement Accuracy | ±0.2% of Full Scale (Voltage/Current) Communication Interface | GE SRTP, Modbus TCP (Mark VIe Backplane Compatible) Power Supply | 24V DC (from Mark VIe Power Module) Operating Temperature | 0°C to 60°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 12 (Chassis Mount) Physical Dimensions | 140mm × 100mm × 30mm Certifications | UL 508, CE, CSA, IEC 61010-1

Product Introduction

The **GE IS210AEPSG2B** is a dedicated power system monitoring module designed for GE’s Mark VIe turbine control system, focusing on real-time supervision and fault diagnosis of the system’s power supply infrastructure. As a critical “power guardian” in GE’s industrial portfolio, the **GE IS210AEPSG2B** continuously tracks key operating parameters of Mark VIe power modules (such as the **IS210BPPBH2B**), including input/output voltage, load current, internal temperature, and energy efficiency. It converts these monitoring data into actionable insights for Mark VIe control modules (like the **IS210MACCH1A**), enabling proactive fault handling and ensuring the stable power supply that is vital for turbine control systems in power plants and industrial facilities.

What makes the **GE IS210AEPSG2B** stand out is its deep integration with the Mark VIe ecosystem and its focus on predictive power management. Leveraging GE’s expertise in industrial power monitoring and turbine control, the **GE IS210AEPSG2B** not only collects real-time power data but also analyzes trends to predict potential failures—such as abnormal voltage fluctuations or overheating in power modules. By transmitting early warning signals to the control system, it avoids unplanned turbine shutdowns caused by power supply issues, directly improving the reliability and operational efficiency of the entire turbine control system.

IS210AEPSG2B

Core Advantages and Technical Highlights

Multi-Channel Comprehensive Monitoring: The **IS210AEPSG2B** features 4 dedicated channels for monitoring power module inputs and 4 channels for outputs, supporting simultaneous supervision of up to 4 Mark VIe power modules. This enables centralized management of the entire power supply system, eliminating the need for separate monitoring devices and simplifying system integration while ensuring full visibility of power flows.

High-Precision Measurement: With ±0.2% full-scale accuracy for voltage and current measurements, the **IS210AEPSG2B** captures subtle changes in power parameters—such as minor voltage drops under peak loads or slight current increases indicating potential module degradation. This precision ensures the **IS210MACCH1A** control module receives reliable data for accurate power system assessment and timely intervention.

Proactive Fault Warning and Diagnosis: The **IS210AEPSG2B** is preloaded with GE’s proprietary power system fault diagnosis algorithms. It triggers immediate alerts for abnormal conditions—including over-voltage, under-voltage, over-current, and over-temperature—and provides diagnostic information (such as fault location and severity) to the Mark VIe HMI. This allows maintenance teams to address issues before they escalate into critical power failures.

Seamless Ecosystem Integration: The **IS210AEPSG2B** communicates directly with the Mark VIe backplane via GE SRTP protocol and supports Modbus TCP for integration with plant-wide SCADA systems. It synchronizes power monitoring data with the **IS210MACCH1A** and HMI interfaces in real time, ensuring consistent data sharing across the control system and enabling unified power management and remote monitoring.

Typical Application Scenarios

In large-scale gas turbine power plants, the **IS210AEPSG2B** serves as the core power monitoring unit for the Mark VIe system. It simultaneously monitors 4 **IS210BPPBH2B** power modules, tracking input voltage from the plant’s main AC grid, output current to control modules (like the **IS210MACCH1A**), and internal temperatures of each power module. When a voltage fluctuation exceeds the threshold, it immediately alerts the control system to switch to backup power, preventing turbine control interruptions.

For industrial cogeneration facilities with redundant power systems, the **IS210AEPSG2B** monitors both main and backup power modules, ensuring seamless power switching. It tracks the load distribution between redundant modules, alerting operators if one module bears excessive current—helping balance loads and extend the service life of power equipment. This is critical for maintaining continuous thermal and electrical supply to manufacturing processes.

In hydroelectric power plants with remote operation, the **IS210AEPSG2B** transmits real-time power module data to the central SCADA system via Modbus TCP. It monitors the efficiency of power modules powered by on-site diesel generators or renewable energy sources, identifying inefficient operation to optimize energy consumption. Its over-temperature alert function also protects power modules from damage in the high-humidity environment of hydro plants.

Related Model Recommendations

**IS210AEPSG1B**: 2-channel variant of **IS210AEPSG2B**, ideal for small Mark VIe systems with fewer power modules, such as compact turbine control setups.

**IS210MACCH1A**: Mark VIe control module that processes monitoring data from **IS210AEPSG2B**, executing fault response strategies for power system anomalies.

**IS210BPPBH2B**: Mark VIe power supply module monitored by **IS210AEPSG2B**, forming a reliable “supply-monitoring” combination for turbine control systems.

**IC754VSF12CTD-JH**: GE VersaMax HMI that displays real-time power monitoring data from **IS210AEPSG2B**, enabling operators to track module status and fault alerts.

**IS210MCCPG1A**: Mark VIe communication module that extends **IS210AEPSG2B**’s connectivity to legacy SCADA systems, facilitating data integration in system upgrades.

**IS210BAPAH1A**: Mark VIe analog input module that complements **IS210AEPSG2B** by collecting sensor data, providing comprehensive system status visibility.

**IS210BDAOH1A**: Mark VIe digital output module that works with **IS210AEPSG2B**, executing control commands (e.g., switching backup power) based on monitoring data.

IS210AEPSG2B

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS210AEPSG2B**, power off the Mark VIe chassis and verify compatibility with the system backplane. Ensure the module receives stable 24V DC power from a dedicated Mark VIe power module. Connect monitoring channels to the input/output terminals of the target power modules using shielded cables to avoid interference. Configure communication parameters (e.g., SRTP address) via Mark VIe Configuration Studio, and set threshold values for fault alerts (e.g., over-voltage limit) according to the power system design.

Maintenance suggestions: Conduct monthly visual inspections of **IS210AEPSG2B**, checking for loose wiring, damaged connectors, and dust accumulation—clean the module with a dry anti-static brush. Calibrate the measurement channels quarterly using a precision voltage/current source to ensure ±0.2% accuracy. Verify fault alert functions semi-annually by simulating abnormal conditions (e.g., low voltage) and confirming system responses. Ensure the control cabinet maintains 0°C to 60°C and good ventilation, and update the module’s firmware annually via GE’s technical support platform.

Service and Guarantee Commitment

GE General Electric provides a 36-month quality guarantee for the **IS210AEPSG2B**, covering manufacturing defects, measurement inaccuracies beyond specifications, and communication failures under normal operating conditions. Our global technical support team offers 24/7 assistance, including remote calibration guidance, fault diagnosis, and firmware update support. Customers receive access to GE’s Mark VIe Configuration Studio and power monitoring system design documentation for the **IS210AEPSG2B** throughout the guarantee period. Priority service clients benefit from 48-hour replacement of defective modules to minimize power system monitoring downtime.