Description

GE IS210BAPAH1A I/O Control Module: Precise Signal Processing for Industrial Automation

Description

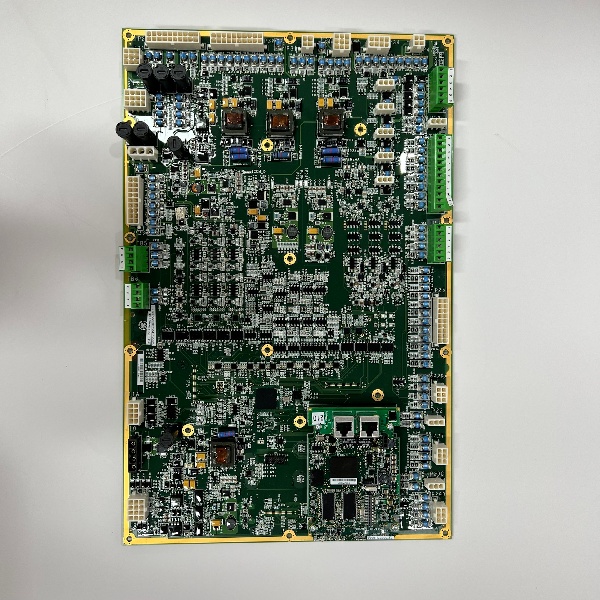

The **IS210BAPAH1A** is a high-precision I/O control module developed by General Electric (GE), specialized in analog and digital signal acquisition, processing, and output for industrial control systems. As a “signal conversion core,” it integrates multi-channel I/O interfaces, high-speed signal conditioning, and anti-interference processing into a rugged design—ensuring accurate data transmission between field sensors/actuators and upper-level controllers (such as PLCs and DCS). Its seamless compatibility with GE’s Mark VIe, Fanuc Series 90, and Allen-Bradley ControlLogix systems makes it a key component in metallurgy, water treatment, and automotive assembly industries—where reliable signal interaction directly affects production accuracy and process stability.

Application Scenarios

A domestic steel mill faced signal interference issues in its continuous casting control system—unstable temperature and pressure signals caused the casting speed to fluctuate, resulting in 5% of steel billets with uneven thickness. After deploying **IS210BAPAH1A** to process 8 channels of analog temperature signals and 16 channels of digital valve control signals, the signal sampling error dropped from ±0.5% to ±0.1%. The module’s differential input design and 16-bit AD conversion precision solved the core pain point of industrial site interference. Plant technicians reported that the billet qualification rate increased to 99.2%, and the frequency of manual parameter adjustment decreased by 70%, significantly reducing labor costs.

Parameter

Main Parameters | Value/Description Annotation

Product Model | **IS210BAPAH1A** GE’s dedicated I/O control part number

Manufacturer | General Electric (GE) Leader in industrial signal processing

Product Category | Analog/Digital I/O Control Module Signal acquisition + output control

Analog Input (AI) | 8 channels, 4-20mA/0-10V Differential input design

Analog Output (AO) | 4 channels, 4-20mA/0-10V High linearity output

Digital Input (DI) | 16 channels, 24VDC Optically isolated

Digital Output (DO) | 8 channels, 24VDC/1A Relay output

AD Conversion Precision | 16-bit ±0.1% Full-scale accuracy

Sampling Rate | 100 Hz per channel Real-time signal capture

Operating Temperature | -25°C to +75°C Adapts to workshop environments

Protection Functions | Overvoltage, reverse polarity, ESD protection Comprehensive signal security

Communication Interface | Modbus RTU, Ethernet/IP Fast data transmission

IS215WETAH1BAGE

Technical Principles and Innovative Values

Innovation Point 1: Differential Anti-Interference Design – **IS210BAPAH1A** adopts differential input for all analog channels, matching with twisted-pair wiring to suppress common-mode interference (up to 1kV). Unlike single-ended input modules, it can effectively filter out electromagnetic interference from high-voltage equipment (such as motors and transformers) in industrial sites, ensuring stable signal acquisition even in complex electromagnetic environments.

Innovation Point 2: Adaptive Signal Calibration – The module is equipped with an automatic calibration algorithm that periodically compares the collected signals with an internal high-precision reference source (error ≤0.01%). It dynamically compensates for drift caused by temperature changes and component aging, eliminating the need for manual calibration (reducing calibration workload by 90% compared with traditional modules) and maintaining long-term measurement accuracy.

Innovation Point 3: Mixed I/O Integration – **IS210BAPAH1A** integrates analog and digital I/O in a single module (8AI+4AO+16DI+8DO), reducing the number of modules required in control cabinets by 50%. Its unified communication interface simplifies system integration, avoiding the compatibility issues of using separate analog and digital modules, and lowering the overall system cost.

Application Cases and Industry Value

Case 1: Water Treatment Plant Process Control – A municipal water treatment plant used **IS210BAPAH1A** to monitor and control its filtration and disinfection processes. The module collected signals from 8 pressure/flow sensors (AI channels) and controlled 4 dosing pumps (AO channels) and 8 solenoid valves (DO channels). Previously, signal interference led to unstable dosing, resulting in unqualified water quality 2 times a month. After deployment, the module’s anti-interference performance stabilized the dosing amount, and the water quality qualification rate reached 100%. The centralized I/O design also reduced the control cabinet space by 30%.

Case 2: Automotive Welding Production Line – An automotive assembly plant in Guangzhou deployed **IS210BAPAH1A** in its robotic welding line. The module collected 6 temperature signals from welding guns (AI) and 12 limit switch signals (DI), then output control signals to 4 welding power supplies (AO) and 6 cooling fans (DO). The module’s 16-bit precision ensured the welding temperature error was within ±1°C, reducing welding defects by 85%. Its fast sampling rate (100Hz) also realized real-time adjustment of welding parameters, improving the production line’s throughput by 12%.

Related Product Combination Solutions

- **IS210BAPAH2A** – Upgrade model with 16AI+8AO channels; suitable for large-scale signal acquisition scenarios.

- **GE IC698ALG220** – Signal conditioning module; enhances **IS210BAPAH1A**’s compatibility with special sensors (such as RTD).

- **IS200IOV001** – I/O expansion module; expands **IS210BAPAH1A**’s digital channels by 32 DI/16 DO.

- **DS200ENET600** – GE Ethernet switch; ensures stable data transmission between **IS210BAPAH1A** and the upper DCS.

- **GE Mark VIe Controller** – Core control unit; processes signals from **IS210BAPAH1A** for centralized control.

- **Allen-Bradley 1756-L81E** – ControlLogix PLC; seamlessly integrates with **IS210BAPAH1A** in mixed-brand systems.

- **GE CR100** – Industrial enclosure; protects **IS210BAPAH1A** from dust and oil mist in workshop environments.

IS215WETAH1BAGE

Installation, Maintenance, and Full-Cycle Support

Installation & Commissioning: **IS210BAPAH1A** adopts a DIN rail-mount design (fits standard 35mm rails) for easy installation in control cabinets. Connect field sensors/actuators to the terminal blocks (color-coded for AI/AO/DI/DO to avoid misconnection), then configure the module via GE’s Proficy I/O Configurator software. The software provides a visual interface to set signal types, scaling ranges, and alarm thresholds, with a self-test function to verify channel integrity—completing commissioning in 40 minutes.

Maintenance & Support: Daily maintenance involves checking the module’s LED status (power/communication/channel fault) and ensuring tight terminal connections. Annual maintenance only requires running the automatic calibration function via software (no disassembly needed). GE provides a 36-month warranty for **IS210BAPAH1A**, including 24/7 remote technical support and on-site troubleshooting. The module’s replaceable terminal blocks allow quick repair of damaged wiring interfaces without replacing the entire module.

Every **IS210BAPAH1A** undergoes strict performance testing, including 200 hours of signal stability testing, electromagnetic compatibility (EMC) testing (meets IEC 61000-4), and temperature cycle testing. It fully complies with IEC 61131-2 and UL 508 standards. For industrial control systems that require accurate and reliable signal interaction, **IS210BAPAH1A** is the optimal I/O control solution. Contact us today to customize a signal processing scheme tailored to your production process.