Description

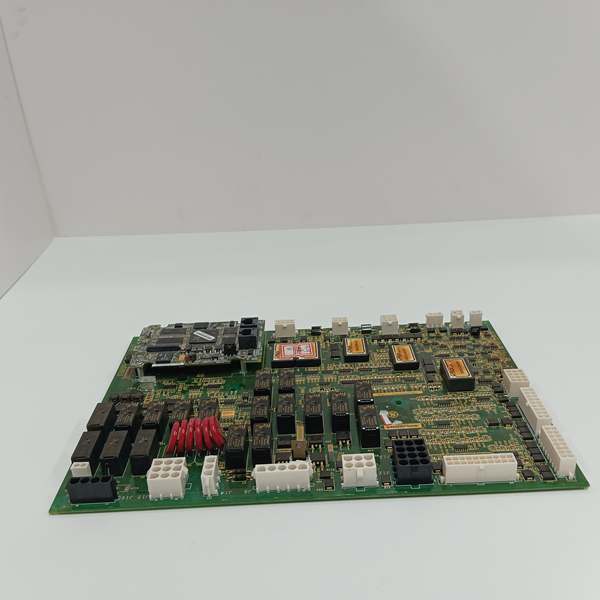

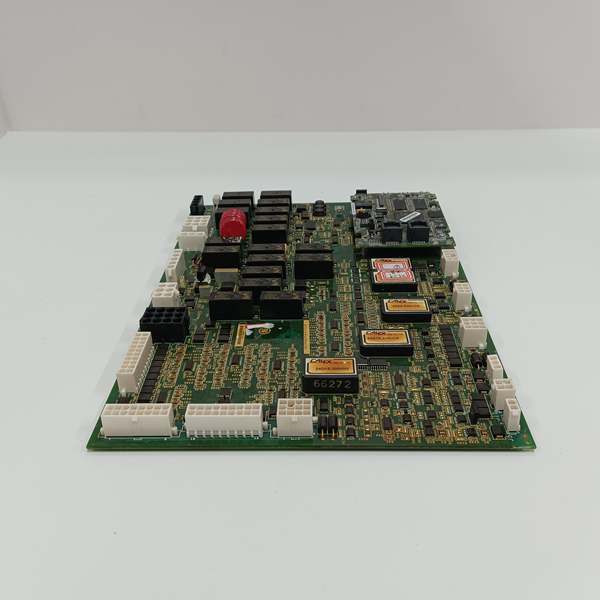

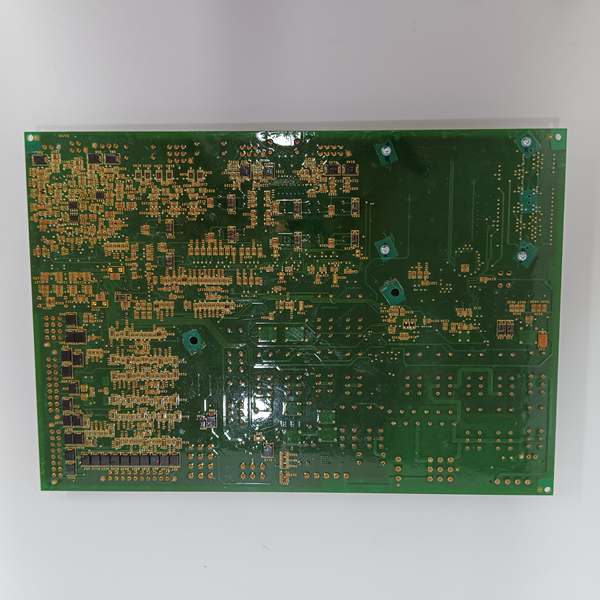

GE IS210BPPBH2B Mark VIe Power Supply Module

Detailed Parameter Table

Parameter Name | Parameter Value ———|——– Product Model | **IS210BPPBH2B** Manufacturer | GE General Electric Product Category | Industrial Power Supply Module Series | Mark VIe (Turbine Control System) Input Voltage | 110/220V AC (Auto-Ranging), 125/250V DC Output Voltage | 24V DC (Regulated) Output Current | 15A (Continuous), 25A (Peak) Efficiency | ≥90% @ Full Load Protection Features | Over-Voltage, Over-Current, Short-Circuit, Over-Temperature Operating Temperature | 0°C to 60°C Storage Temperature | -40°C to 85°C Protection Rating | IP20 (Module), NEMA 12 (Chassis Mount) Physical Dimensions | 150mm × 110mm × 35mm Certifications | UL 508, CE, CSA

Product Introduction

The **GE IS210BPPBH2B** is a reliable power supply module designed for GE’s Mark VIe turbine control system, serving as the stable energy backbone for critical control components in conventional industrial environments. As a cost-effective power management solution in GE’s industrial portfolio, the **GE IS210BPPBH2B** delivers regulated 24V DC power to Mark VIe control modules (such as the **IS210MACCH1A**), I/O modules, and safety systems—ensuring uninterrupted operation of turbine control functions. Its auto-ranging input design and robust protection features make it adaptable to standard power grid conditions, a key requirement for onshore power plants, manufacturing cogeneration facilities, and industrial turbine applications.

What distinguishes the **GE IS210BPPBH2B** is its seamless integration with the Mark VIe ecosystem and focus on practical, cost-efficient performance. Leveraging GE’s expertise in power electronics and industrial system design, the **GE IS210BPPBH2B** maintains precise voltage regulation even during typical load fluctuations—common scenarios during turbine start-up and grid load changes. By providing consistent power in standard operating conditions, it enhances the reliability of the entire control system, reducing the risk of unplanned downtime and associated costs—ideal for mid-sized generation facilities and industrial turbine applications with conventional environmental demands.

Core Advantages and Technical Highlights

Dual-Input Auto-Ranging: The **IS210BPPBH2B** supports both AC (110/220V) and DC (125/250V) input with automatic voltage sensing, eliminating manual configuration and adapting to standard power grid variations. This flexibility allows deployment in regions with different mains voltages, from 110V AC (North America) to 220V AC (Europe/Asia), simplifying global procurement and installation.

Stable Regulated Output: Delivering 24V DC with ±0.5V precision, the **IS210BPPBH2B** maintains consistent power to Mark VIe components even under 15A continuous load. Its advanced switching topology ensures minimal voltage ripple (<50mV), protecting sensitive electronics in control modules like the **IS210MACCH1A** from signal interference and performance degradation—critical for precise turbine speed and load control.

Comprehensive Protection Mechanisms: The **IS210BPPBH2B** integrates multi-layer protection, including over-voltage (28V DC cutoff), over-current (25A peak limit), short-circuit, and over-temperature safeguards. In fault conditions, it triggers rapid current limiting or shutdown, preventing damage to both the power supply and connected control components—avoiding cascading failures in the turbine control system.

Efficient Thermal Performance: With ≥90% efficiency at full load and an operating temperature range of 0°C to 60°C, the **IS210BPPBH2B** minimizes energy waste and heat generation. Its passive heat dissipation design, using high-conductivity aluminum housing, eliminates fan-related maintenance and failure risks—ensuring reliable operation in standard turbine control cabinets with adequate ventilation.

Typical Application Scenarios

In onshore gas and steam power plants, the **IS210BPPBH2B** acts as the primary power source for Mark VIe control cabinets. It supplies regulated 24V DC to the **IS210MACCH1A** control module, I/O modules, and HMI interfaces, adapting to standard 110/220V AC mains. Its stable output ensures precise turbine control during load changes, while over-current protection safeguards against electrical faults from on-site auxiliary equipment.

For industrial manufacturing cogeneration facilities, the **IS210BPPBH2B** powers Mark VIe systems controlling on-site steam turbines, balancing electrical output and thermal energy for production processes. It integrates with both main AC power and backup DC battery systems, switching seamlessly during grid outages to maintain power to safety controls—ensuring uninterrupted thermal supply for manufacturing lines.

In small to mid-sized hydroelectric power plants (onshore), the **IS210BPPBH2B** provides stable power to Mark VIe turbine governor controls. It operates reliably within the 0°C to 60°C range of typical hydro plant environments, powering the **IS210MACCH1A** and sensor modules that adjust turbine blades based on water flow. Its auto-ranging AC input adapts to local mains voltages, simplifying installation in regional hydro facilities.

Related Model Recommendations

**IS210BPPBH1B**: 10A variant of **IS210BPPBH2B**, ideal for small-scale Mark VIe systems with lower power demands, such as compact turbine control setups.

**IS210MACCH1A**: Mark VIe control module directly powered by **IS210BPPBH2B**, forming the core control-power combination for mid-sized onshore turbines.

**IS210BPPBH2B-R**: Redundant power supply kit with two **IS210BPPBH2B** modules, ensuring 100% power availability for critical onshore turbine systems.

**IS210MCPMG1A**: Power monitoring module that pairs with **IS210BPPBH2B** to track voltage, current, and efficiency, enabling predictive maintenance for on-site teams.

**IS210IAIH1A**: Analog input module, receiving stable power from **IS210BPPBH2B** to collect pressure, temperature, and vibration data from turbine sensors.

**IS210BPPBH3B**: 20A high-capacity variant of **IS210BPPBH2B**, designed for large Mark VIe systems with multiple control and I/O modules in onshore power plants.

**IC754VSF12CTD-JH**: Standard GE VersaMax HMI, powered by **IS210BPPBH2B** to display real-time turbine data in onshore control rooms.

IS210BPPBH2B

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing **IS210BPPBH2B**, disconnect all primary power sources and verify the input voltage matches the plant’s supply (110/220V AC or 125/250V DC). Ensure the Mark VIe chassis has a dedicated power slot and use wiring sized for 15A continuous current (16 AWG minimum for DC outputs). Use insulated tools for terminal connections, secure the module with mounting screws to prevent vibration-induced loosening, and label wires clearly to avoid polarity errors.

Maintenance suggestions: Conduct monthly visual inspections of **IS210BPPBH2B**, checking for loose terminals, discolored components, and dust accumulation—clean ventilation slots with compressed air (max 0.3 MPa). Measure output voltage quarterly using a calibrated multimeter to ensure it remains within 23.5-24.5V DC. Replace the module if efficiency drops below 85% or if protection alarms trigger frequently. Ensure the control cabinet maintains adequate ventilation to keep the module within its 0°C to 60°C operating range.

Service and Guarantee Commitment

GE General Electric provides a 30-month quality guarantee for the **IS210BPPBH2B**, covering manufacturing defects, output regulation failures, and protection system malfunctions under normal operating conditions. Our global technical support team offers 24/7 assistance, including remote troubleshooting, installation guidance, and firmware updates. Customers receive access to GE’s Power Supply Configuration Tool and technical documentation for the **IS210BPPBH2B** throughout the guarantee period. Priority service clients benefit from 48-hour replacement of defective modules to minimize turbine control system downtime.