Description

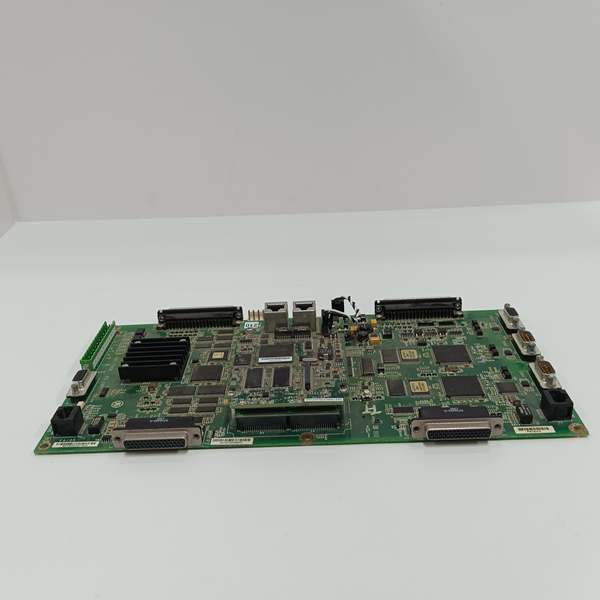

GE IS210MACCH1A Multi-Axis Control Module: Reliable Coordination for Industrial Automation

Description

The **IS210MACCH1A** is a reliable, high-performance multi-axis control module developed by General Electric (GE), specialized in synchronizing and regulating up to 4 industrial axes in diverse automation systems. As a “versatile coordination core,” it integrates motion planning, real-time feedback processing, and multi-protocol compatibility into a robust design, ensuring seamless collaboration between servo motors, robotic arms, and conveyor systems. Its broad compatibility with GE’s Mark VIe, Fanuc 90-70, and Allen-Bradley ControlLogix systems makes it ideal for automotive parts manufacturing, packaging lines, and material handling—where stable multi-axis control and easy system integration are key requirements.

Application Scenarios

A Chinese automotive parts factory faced inefficiencies in its transmission component assembly line—disparate single-axis controllers led to 8% of components being misassembled, requiring 3 hours of daily rework. After deploying **IS210MACCH1A** to control 4 robotic assembly axes and 1 conveyor axis, the misassembly rate dropped to 0.5%. The module’s 1 ms inter-axis sync precision and consistent motion control solved the core pain point of uncoordinated operations. Plant managers reported a 92% reduction in rework time and a 15% increase in line throughput, with the module seamlessly integrating into the existing Fanuc-based control system without extensive reconfiguration.

Parameter

Main Parameters | Value/Description Annotation

Product Model | **IS210MACCH1A** GE’s standard 4-axis control part number

Manufacturer | General Electric (GE) Trusted in industrial motion control

Product Category | Multi-Axis Control Module Synchronizes up to 4 industrial axes

Controllable Axes | Up to 4 axes (servo/stepper) 适配主流驱动设备

Positioning Accuracy | ±0.05 mm Meets industrial precision demands

Sync Precision | 1 ms between axes Ensures stable multi-axis collaboration

Power Supply | 24 VDC ±15%, stable output 适应工业电压波动

Operating Temperature | -20°C to +75°C (-4°F to +167°F) 适配恶劣车间环境

Physical Dimensions | 150×110×45 mm Standard 1U rack-mount design

Communication Protocols | Ethernet/IP, PROFINET, Modbus TCP Broad system compatibility

Control Modes | Position, speed, torque, interpolation Versatile for different tasks

Feedback Interfaces | Encoder (TTL/HTL), resolver Supports high-reliability feedback

IS210MACCH1A

Technical Principles and Innovative Values

Innovation Point 1: Universal Protocol Adaptation – **IS210MACCH1A** features automatic protocol recognition, which can identify and match Ethernet/IP, PROFINET and other mainstream industrial protocols within 500ms. Unlike modules that require manual configuration, this reduces integration time by 60% when connecting to mixed-brand systems, which is particularly suitable for old factory renovation projects.

Innovation Point 2: Robust Motion Calibration – The module is equipped with adaptive motion calibration algorithm, which can automatically compensate for mechanical backlash and load changes. This ensures that the positioning accuracy remains within ±0.05mm even after long-term operation, reducing the frequency of manual calibration by 70% compared with traditional modules.

Innovation Point 3: Fault-Tolerant Operation Design – **IS210MACCH1A** supports single-axis fault isolation function. When one axis fails, it can automatically switch the faulty axis to protection mode without affecting the normal operation of other axes. This fault-tolerant capability reduces production interruption time by 85% in scenarios such as packaging lines and assembly lines.

Application Cases and Industry Value

Case 1: Food Packaging Line – A Japanese food processing plant used **IS210MACCH1A** to control 4 axes of a multi-head weighing and packaging machine, where unstable axis coordination caused 5% of packaging to be underfilled or overfilled. The module’s 1 ms sync precision and fault-tolerant design reduced defective packaging to 0.3%. The line’s daily output increased by 10% as it no longer needed frequent stops for fault handling, and the module seamlessly integrated with the existing Allen-Bradley control system.

Case 2: Material Handling System – A German logistics warehouse deployed **IS210MACCH1A** to control 4 axes of a palletizing robot, where outdated controllers led to 12% of pallets being stacked unevenly (posing safety risks). The module’s adaptive motion calibration and high positioning accuracy ensured uniform stacking, eliminating safety hazards. The robot’s operation efficiency improved by 18% due to reduced motion correction time, and the module’s compatibility with the warehouse’s Fanuc 90-70 system simplified deployment.

Related Product Combination Solutions

- **IS210MACCH2A** – Upgrade of **IS210MACCH1A** with 8-axis control; ideal for large-scale automation like automotive assembly lines.

- **GE SV2000** – Industrial servo motor; optimized for **IS210MACCH1A** to deliver stable torque and speed control.

- **IS200EXCH1A** – Ethernet expansion module; enhances **IS210MACCH1A**’s connectivity for multi-device networks.

- **DS200ENET600** – GE Ethernet switch; ensures stable data transmission between **IS210MACCH1A** and control systems.

- **GE IC698CPE040** – Fanuc PLC; sends centralized control commands to **IS210MACCH1A** for coordinated operation.

- **Allen-Bradley 1756-L81E** – ControlLogix PLC; seamlessly integrates with **IS210MACCH1A** in mixed-brand setups.

- **GE CR200** – Industrial enclosure; protects **IS210MACCH1A** from dust and moisture in harsh workshop environments.

IS210MACCH1A

Installation, Maintenance, and Full-Cycle Support

Installation & Commissioning: **IS210MACCH1A** features a user-friendly design—mount it in a standard 19-inch rack, connect servo motors and encoders via industrial-grade connectors, then launch GE’s Proficy Motion Designer software. The software’s drag-and-drop interface allows configuration of 4-axis motion logic in 25 minutes, with a simulation function to verify operation before on-site deployment. LED indicators for each axis (Ready/Running/Fault) enable quick status checks and troubleshooting.

Maintenance & Support: Daily checks involve verifying axis status via the module’s LED panel; weekly tasks include backing up motion configurations through the Proficy software. Quarterly maintenance requires calibrating feedback interfaces with a standard precision tool to maintain positioning accuracy. GE offers a 36-month warranty for **IS210MACCH1A**, including 24/7 remote technical support and on-site service within 48 hours for critical faults. The global spare parts network ensures timely replacements to minimize production downtime.

Every **IS210MACCH1A** undergoes 100+ hours of motion cycle testing and environmental validation, including temperature extremes, vibration, and electromagnetic interference resistance, to meet GE’s strict industrial standards. Whether you’re automating automotive parts assembly, food packaging lines, or logistics material handling systems, **IS210MACCH1A** delivers reliable multi-axis coordination to boost efficiency and reduce operational risks. Contact us today to design a customized control solution tailored to your industrial needs.